Cerium dioxide nanoparticle reinforced tin silver copper composite soldering paste and preparation method thereof

A nanoparticle and cerium oxide technology, which is applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of poor mechanical strength, insufficient fatigue resistance, and poor wettability of the interface metal connection layer, and achieve improved mechanical properties. Performance, inhibition of grain growth, and the effect of reducing production and preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add nano-cerium oxide powder (particle size: 10-30nm) with a mass fraction of 0.10% to tin-silver-copper lead-free solder paste with a mass ratio of 99.0:0.3:0.7, and mechanically stir for more than 45 minutes to ensure that the nano-cerium oxide The particles are uniformly distributed in the tin-silver-copper lead-free solder paste, and the cerium dioxide nanoparticle-enhanced tin-silver-copper composite solder paste is obtained. Take a small amount of solder paste on the copper plate, and make a sample after 30s of industrial reflow process, and observe its cross-sectional electron microscope scanning image (such as figure 1 ), the average thickness of the IMC is 1.606 μm, and the shape tends to be stable, indicating that ceria doping plays a role in inhibiting the growth and refinement of IMC.

Embodiment 2

[0025] Add nano-cerium oxide powder (particle size: 10-30nm) with a mass fraction of 0.25% to tin-silver-copper lead-free solder paste with a mass ratio of 99.0:0.3:0.7, and mechanically stir for more than 45 minutes to ensure that the nano-cerium oxide The particles are uniformly distributed in the tin-silver-copper lead-free solder paste, and the cerium dioxide nanoparticle-enhanced tin-silver-copper composite solder paste is obtained. Take a small amount of solder paste on the copper plate, and make a sample after 30s of industrial reflow process, and observe its cross-sectional electron microscope scanning image (such as figure 2 ), the average thickness of its IMC is 2.038 μm. In the case of the same reflow time, the inhibitory effect of higher content of ceria doping may not be so obvious.

Embodiment 3

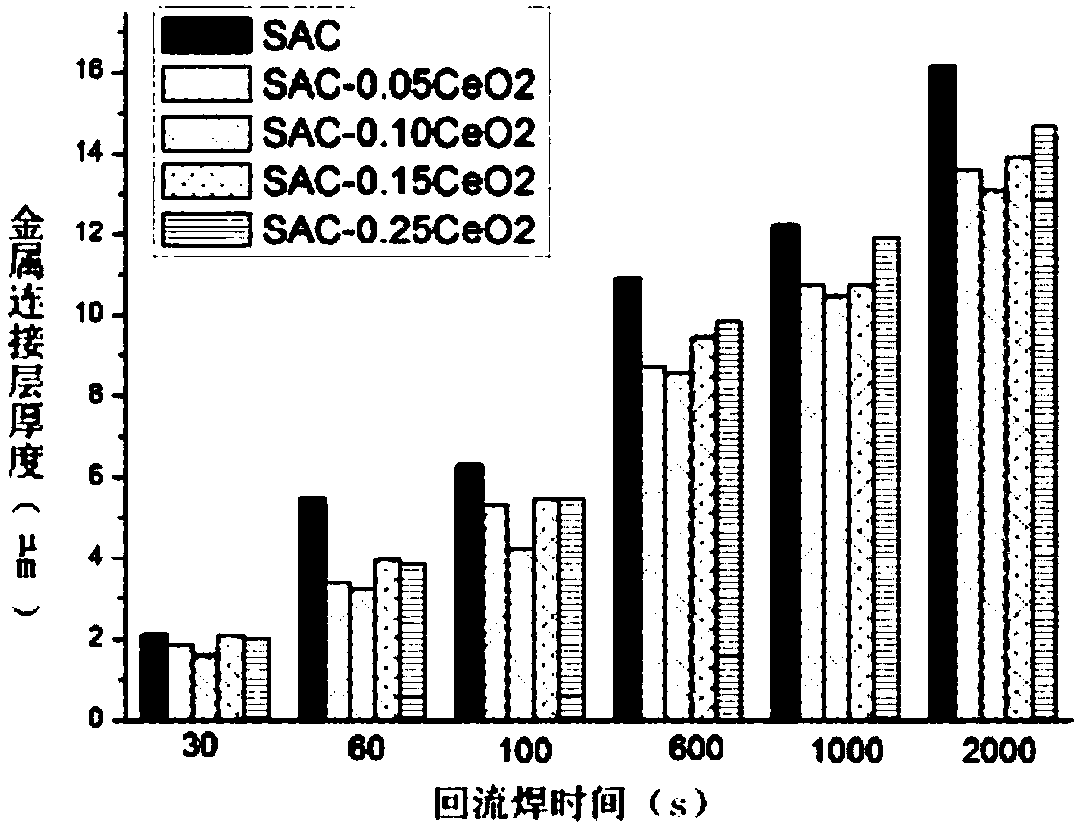

[0027] Add 0.05%, 0.10%, 0.15%, 0.20%, 0.25% nanometer ceria powder (particle size: 10-30nm) to the tin-silver-copper lead-free solder paste with a mass ratio of 99.0:0.3:0.7 During the process, the mechanical stirring was performed for more than 45 minutes to ensure that the cerium dioxide nanoparticles were uniformly distributed in the tin-silver-copper lead-free solder paste, and the cerium dioxide nanoparticle-enhanced tin-silver-copper composite solder paste was obtained.

[0028] Then reflow soldering for 60s, 100s, 600s, 1000s, 2000s respectively.

[0029] Calculate the thickness of the IMC and make a bar graph such as image 3 shown. Among them, SAC indicates that CeO was not added 2 Nanoparticle SnAgCu solder paste; SAC-x (x=0.05, 0.10, 0.15, 0.20, 0.25) CeO 2 Indicates that the mass fraction x% of CeO is added to the SnAgCu solder paste 2 nanoparticles.

[0030] It can be seen that when the added content is 0.10%, the inhibitory effect of nano-cerium oxide parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com