Sludge gas heat carrier graded low-temperature pyrolysis system and method

A technology of gas heat carrier and low-temperature pyrolysis, which is applied in the fields of pyrolysis treatment of sludge, dehydration/drying/thickened sludge treatment, special form of dry distillation, etc. Problems such as high tar dust content, to achieve the effect of shortening the pyrolysis time, shortening the pyrolysis time, and efficient heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

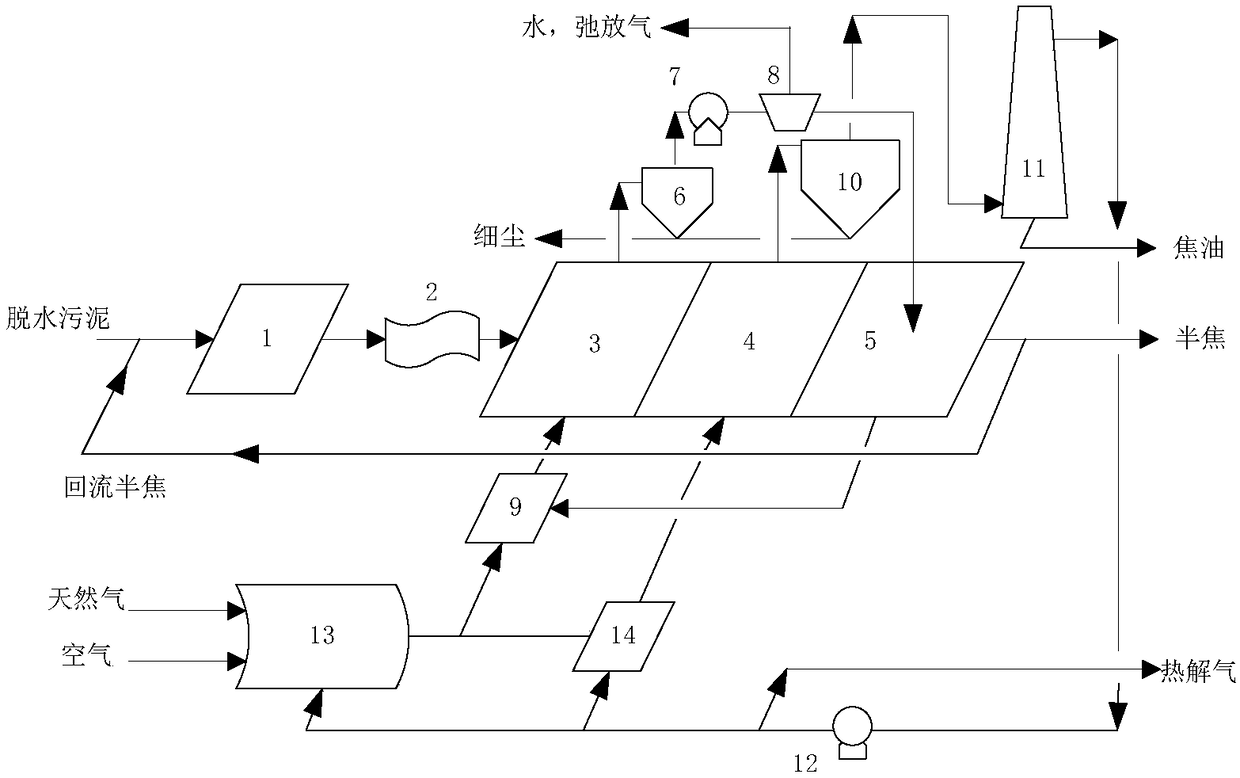

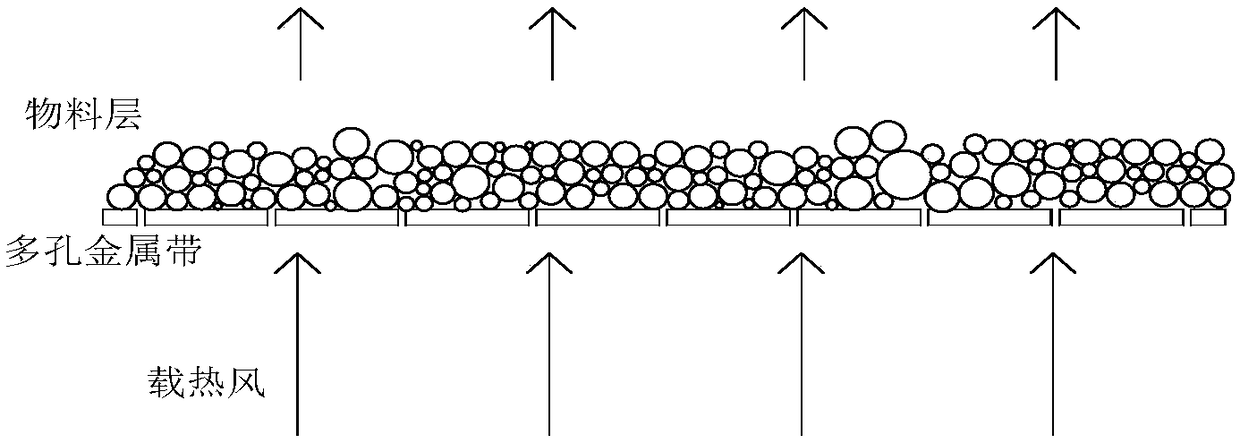

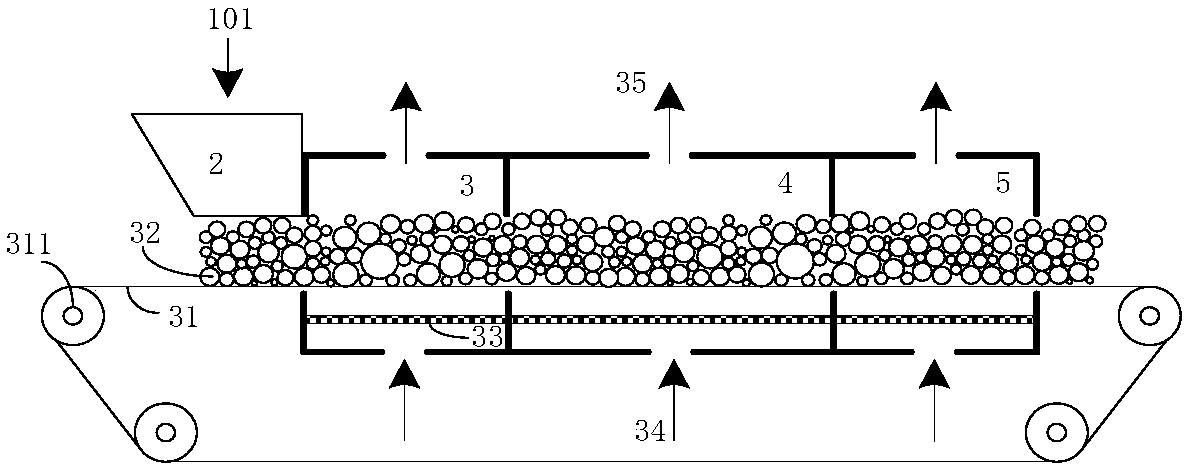

[0027] The present invention includes forming-distributing system, drying-coke CDQ system, pyrolysis system and separation-recovery system, wherein, in the forming-distributing system, the dehydrated sludge and non-spontaneous semi-coke after dry quenching are fully Stir and mix to form spherical particles, which are distributed on the porous metal belt driven by rollers with a certain thickness, and then enter the drying-CDQ system. The hot flue gas passes through the air distribution chamber and the porous metal belt under the drying reactor, and passes through the The material layer takes away moisture and fine dust particles; the water-containing and dust-containing hot flue gas passes through the indirect water-cooled cyclone separator, is pressurized by the fan, and is sent from the upper part to the air distribution cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com