Modified sulfoaluminate cement waterproof material and preparation technique thereof

A technology of sulfoaluminate cement and waterproof material, which is applied in the field of cement-based waterproof material, can solve the problems of poor ductility base layer of rigid waterproof material, poor ductility and toughness of waterproof material, and inability to be activated twice, so as to improve the performance of the waterproof material. Base adaptability, improved dispersion and rheological properties, high ductility and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

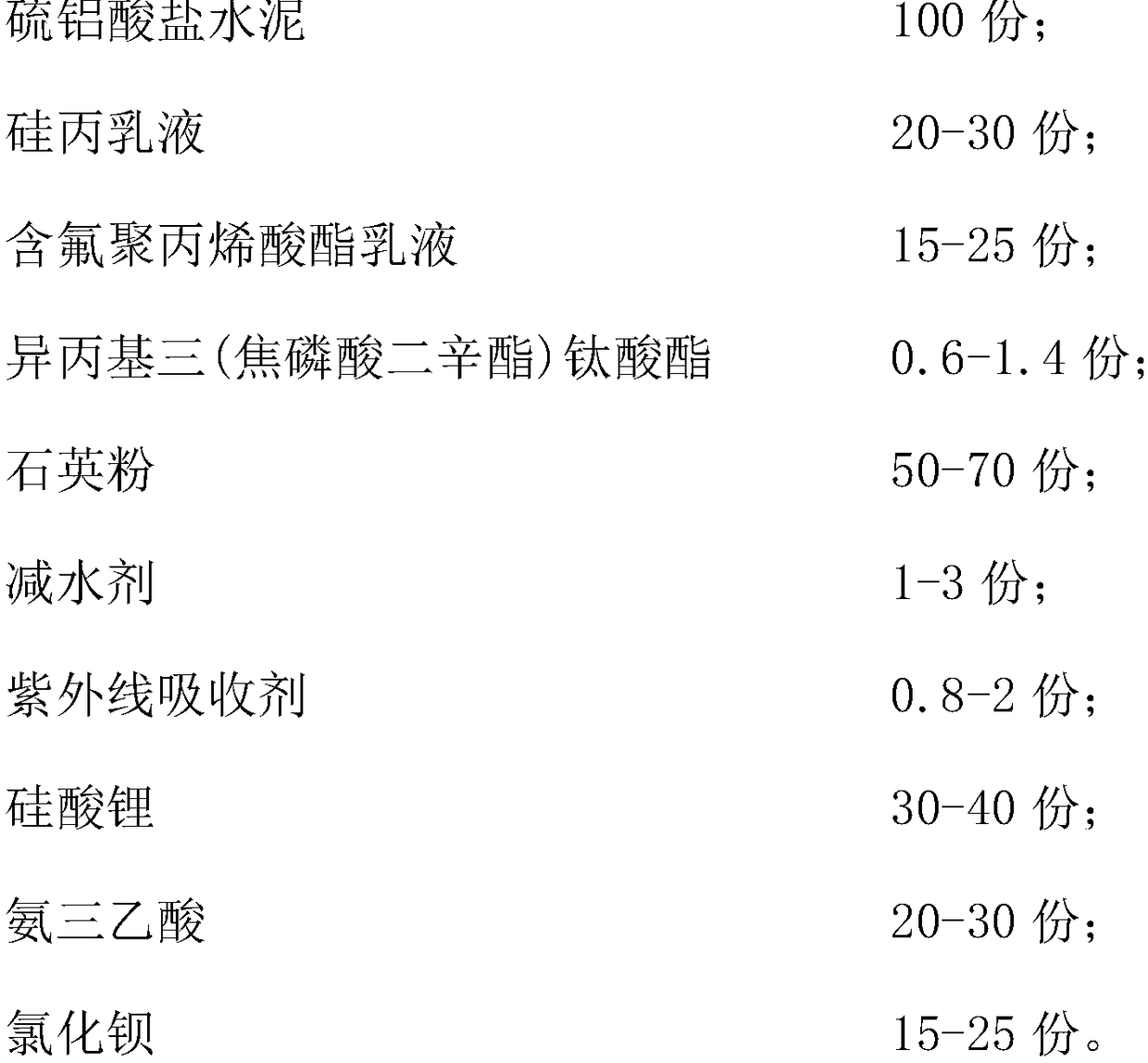

[0020] A modified sulphoaluminate cement waterproof material, comprising the following raw materials in parts by weight:

[0021]

[0022]

[0023] The preparation process of the above-mentioned modified sulphoaluminate cement waterproof material comprises the following steps:

[0024] S1: Add isopropyl tri(dioctyl pyrophosphate) titanate to sulphoaluminate cement and stir for 1 hour to obtain surface chelated sulphoaluminate cement, then add silicon acrylic emulsion and fluorine-containing polyacrylic acid In the mixed emulsion of ester emulsion, heat it to 60°C, keep it warm and stir for 3 hours to get modified sulfoaluminate cement;

[0025] S2: After cooling the modified sulfoaluminate cement to normal temperature, mix it with quartz powder, sodium lignosulfonate, phenyl o-hydroxybenzoate, lithium silicate, nitrilotriacetic acid and barium chloride to obtain the obtained The above waterproof material.

Embodiment 2

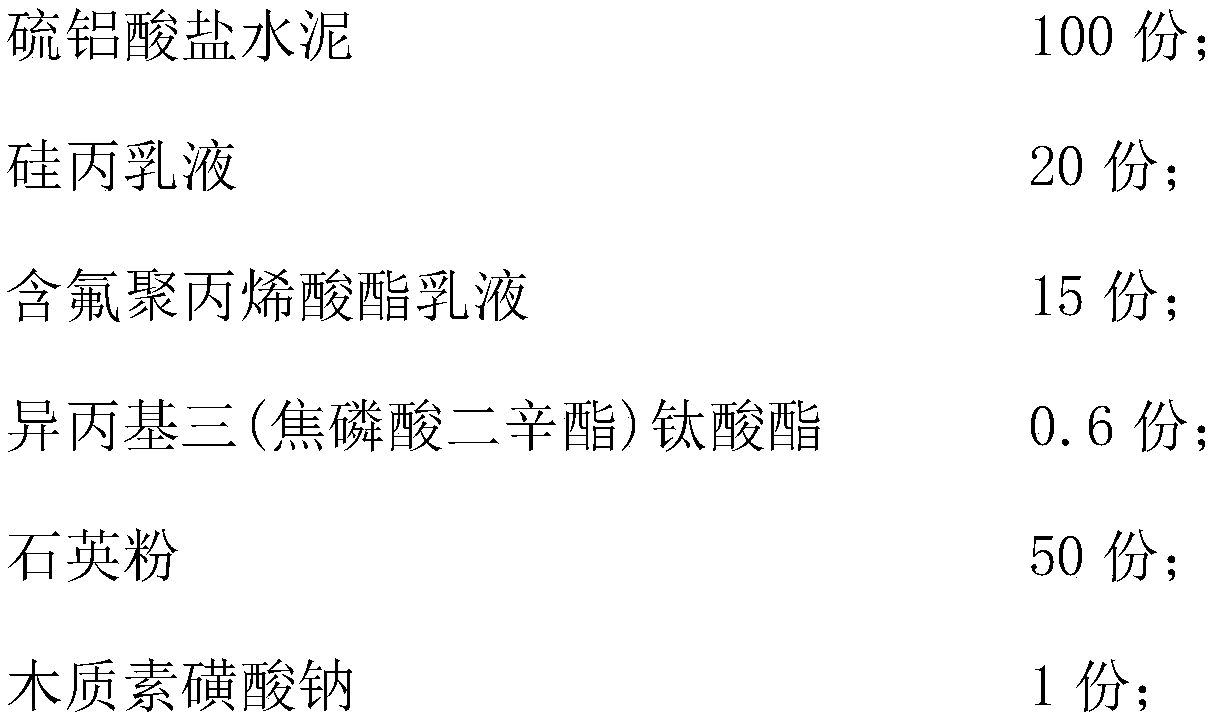

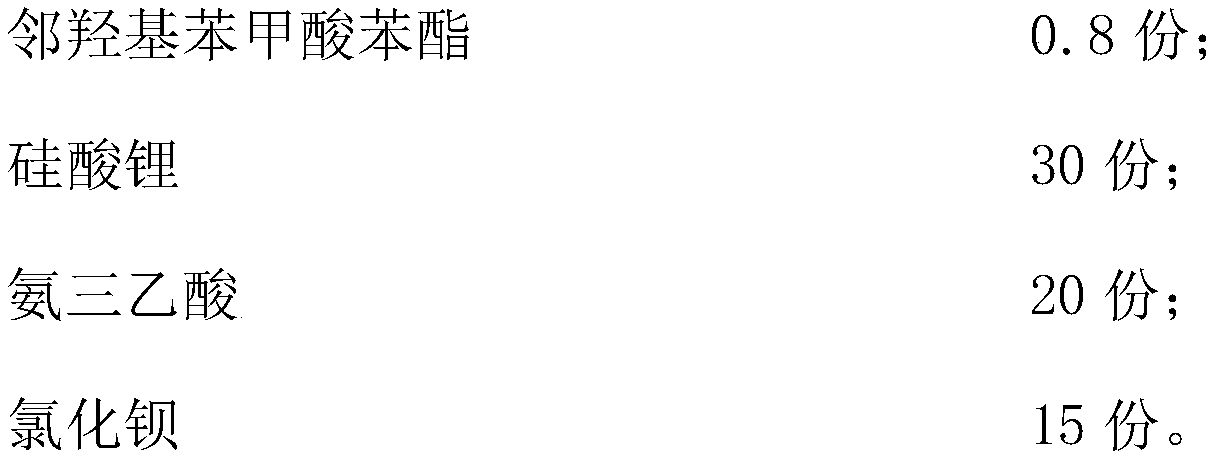

[0027] A modified sulphoaluminate cement waterproof material, comprising the following raw materials in parts by weight:

[0028]

[0029]

[0030] The preparation process of the above-mentioned modified sulfoaluminate cement waterproof material is the same as that in Example 1, except that: S1: the co-heating temperature is 70°C, and the heat preservation and stirring time is 4 hours.

Embodiment 3

[0032] A modified sulphoaluminate cement waterproof material, comprising the following raw materials in parts by weight:

[0033]

[0034] The preparation process of the above-mentioned modified sulfoaluminate cement waterproof material is the same as that in Example 1, except that: S1: the co-heating temperature is 80° C., and the heat preservation and stirring time is 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com