Preparation method of graphene/molybdenum disulfide/cadmium sulfide composite sensing material

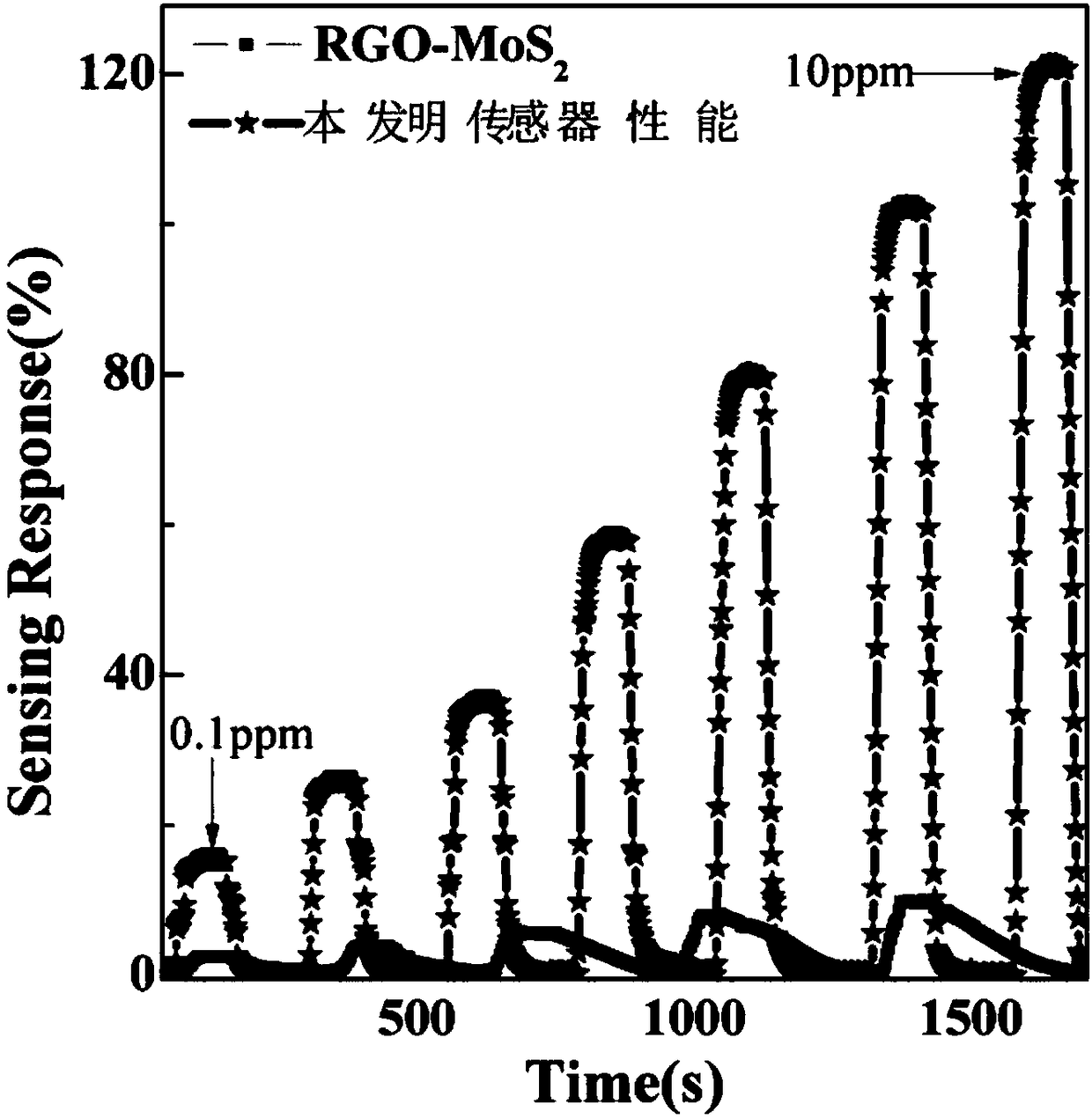

A molybdenum disulfide and composite material technology, which is applied in the material field to achieve the effects of convenient operation, strong thermal stability and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 5 grams of graphite powder and 6 grams of potassium nitrate were put into 230 milliliters of concentrated sulfuric acid for gentle mechanical stirring. 20 g of potassium permanganate was gradually added to the stirred mixture, which was maintained at 40°C for 6 hours. Then add 160 milliliters of distilled water to mix and dilute, keep at 70°C for 30 minutes, then dilute with 500 milliliters of distilled water, then add 6 milliliters of 30% hydrogen peroxide in the mixture to form a brown-yellow product. The mixture was centrifuged and washed with distilled water to remove metal ions and acids. Afterwards, the mixture was dialyzed for a week, and the graphene oxide samples were vacuum-dried at 60°C.

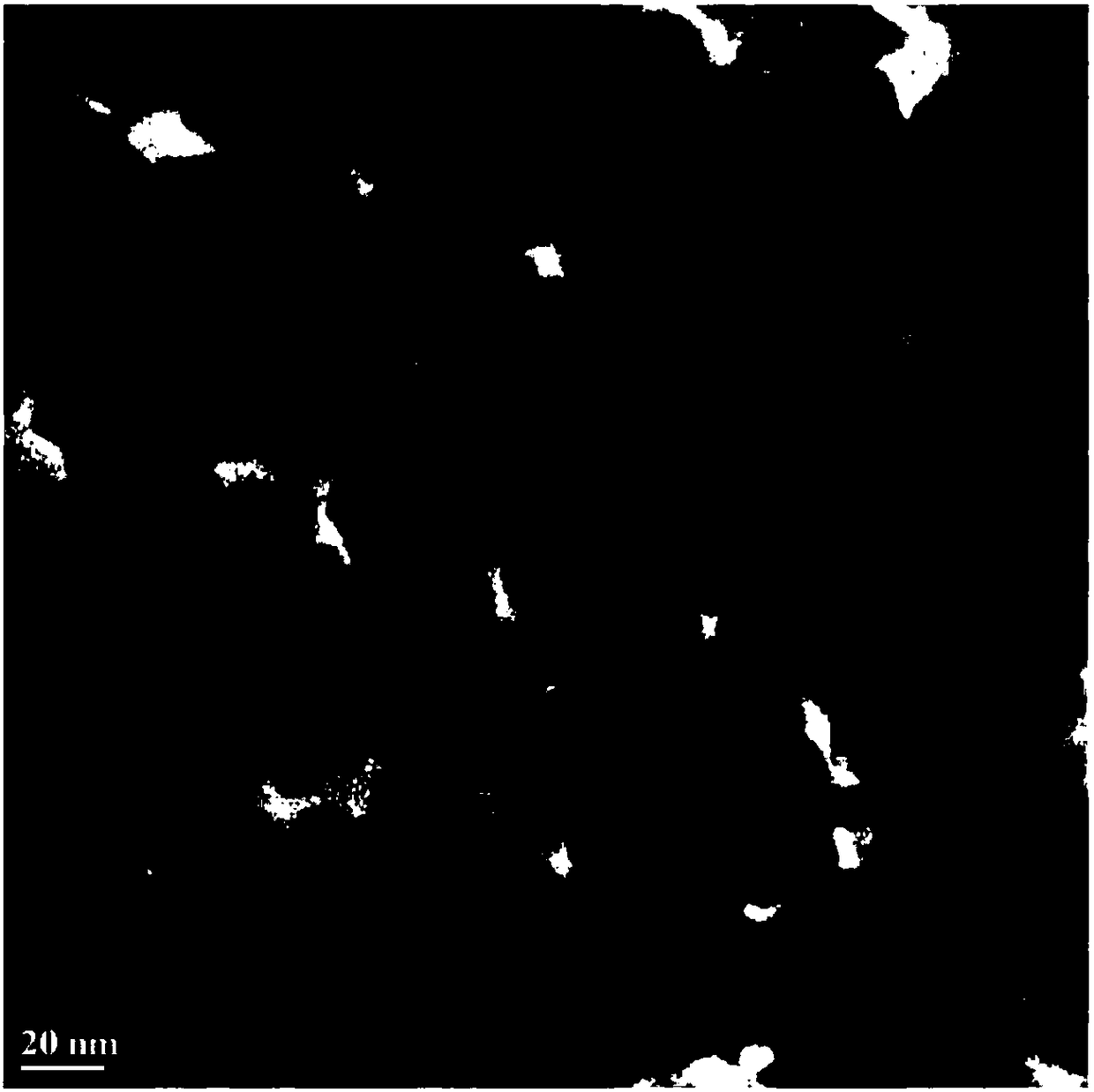

[0024] Graphene oxide-molybdenum disulfide composites were synthesized by hydrothermal method. Weigh 0.1 g of graphene oxide and add 80 ml of distilled water for ultrasonic dispersion. Then, sodium molybdate and thiourea were weighed and added to the above mixture at a m...

Embodiment 2

[0028] 3 grams of graphite powder and 5 grams of potassium nitrate were put into 180 milliliters of concentrated sulfuric acid for gentle mechanical stirring. 18 g of potassium permanganate were gradually added to the stirred mixture, which was maintained at 40°C for 12 hours. Then add 180 milliliters of distilled water to mix and dilute, keep at 70° C. for 60 minutes, then dilute with 500 milliliters of distilled water, then add 6 milliliters of 30% hydrogen peroxide in the mixture to form a brown-yellow product. The mixture was centrifuged and washed with distilled water to remove metal ions and acids. Afterwards, the mixture was dialyzed for two weeks, and the graphene oxide samples were vacuum-dried at 60°C.

[0029] Graphene oxide-molybdenum disulfide composites were synthesized by hydrothermal method. Weigh 0.15 g of graphene oxide and add 100 ml of distilled water for ultrasonic dispersion. Then, sodium molybdate and thiourea were weighed and added to the above mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com