Preparation method and application of a nano flower-like polypyrrole manganese oxide composite material

A composite material, a technology of manganese oxide is applied in the field of preparation of nano-flower-like polypyrrole-manganese oxide composite materials, which can solve the problems of difficult protonation, insoluble in organic solutions, difficult processing, etc., and improve the ability to store electric charges. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

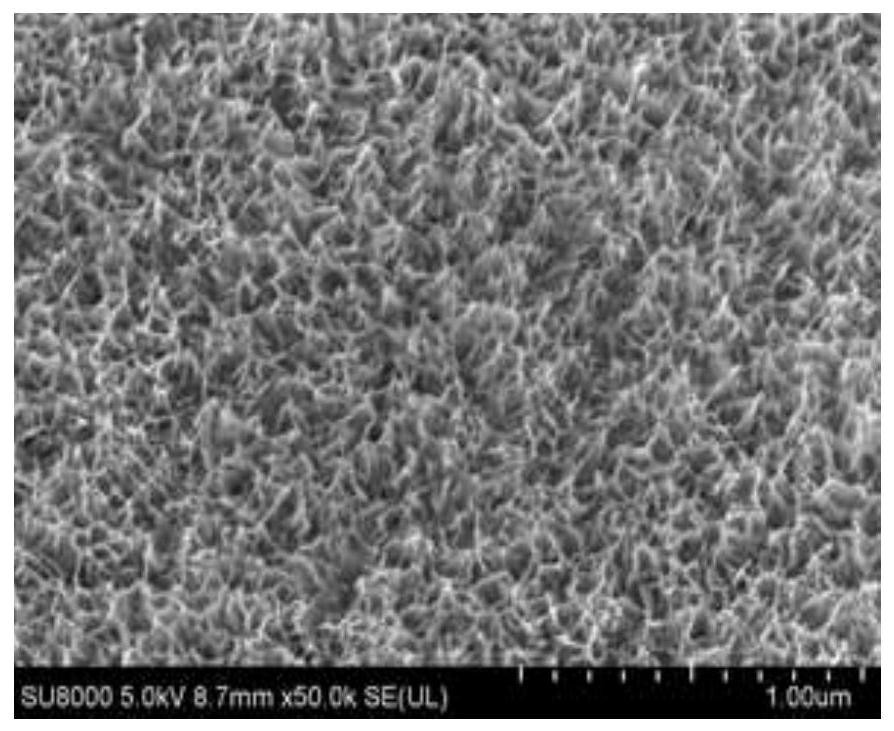

[0021] Take 0.03M manganese acetate, 0.05M ammonium acetate and 0.2mL pyrrole, and react for 45 minutes under the condition of constant potential 0.9Vvs. manganese composite; then rinsed with deionized water and dried. That is, the electrochemical co-deposition of polypyrrole and manganese oxide can use the nano-flower-like structure of manganese oxide to further guide the structure of the electrode surface during pyrrole polymerization, and then prepare nano-flower-like polypyrrole-manganese oxide composite materials, such as figure 1 .

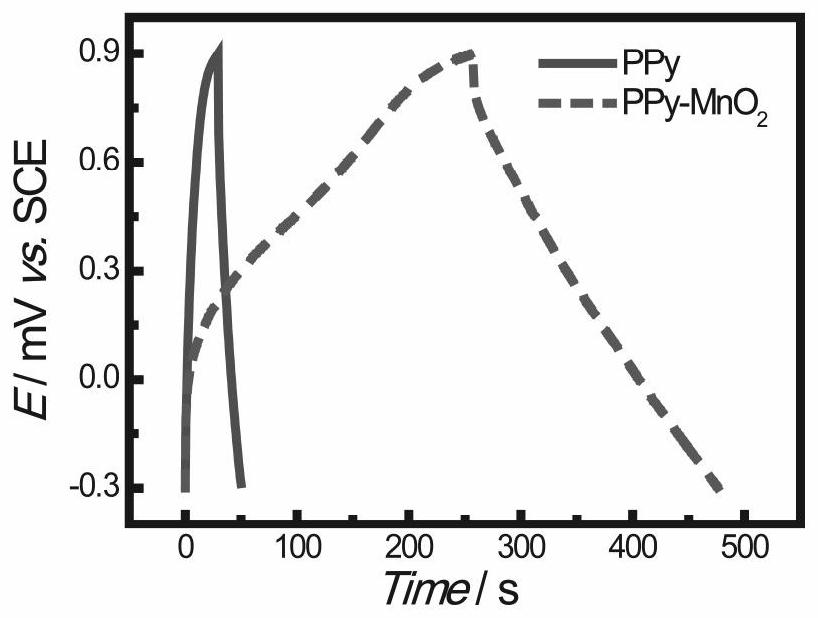

[0022] at 0.5M Na 2 SO 4 In the solution, the nano flower-like polypyrrole-manganese oxide composite material and polypyrrole are used for constant potential charge and discharge at 2mA / cm2, such as figure 2 As shown, the nanoflower-like polypyrrole-manganese oxide composite has a longer discharge time, and its ability to store charges is far superior to that of polypyrrole. The nanoflower-like composite structure increases the specific...

Embodiment 2

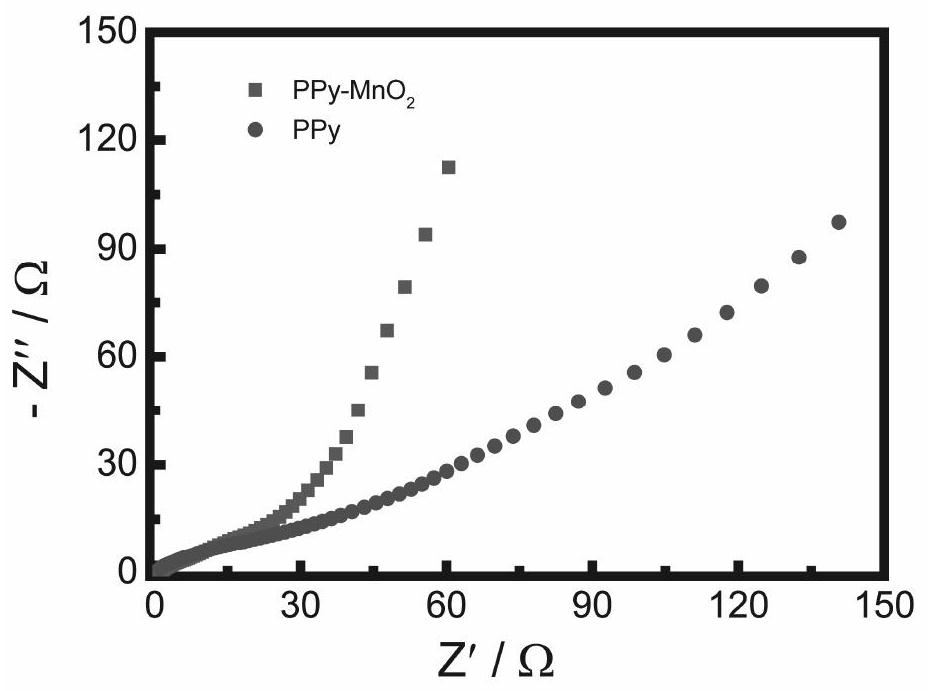

[0024] at 0.5M Na 2 SO 4 AC impedance applications of nanoflower-like polypyrrole-manganese oxide composites and polypyrrole in solution, such as image 3 As shown, no semicircle appears in the high-frequency domain, indicating that the charge transfer resistance at the electrode-electrolyte interface is negligible. In the low-frequency domain, the nanoflower-like PPyrrole-manganese oxide composite shows a steep slope, which means it has a smaller ion diffusion resistance than PPyrrole.

Embodiment 3

[0026] The nano-flower-like polypyrrole-manganese oxide composite material prepared in Example 1 and polypyrrole are assembled into a symmetrical supercapacitor, and the device assembled with the nano-flower-like polypyrrole-manganese oxide composite material and polypyrrole is charged in less than 1 minute In the case of , you can power the LED bulb for 7 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com