Energy storage film with high breakdown field strength and preparation method thereof

A high-breakdown and thin-film technology, which is applied to fixed capacitor components and fixed capacitor dielectrics, can solve problems such as low energy storage density, complex performance regulation process, and low breakdown field strength of energy storage films, reaching the annealing temperature The effect of reducing, simple process, and small interlayer stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

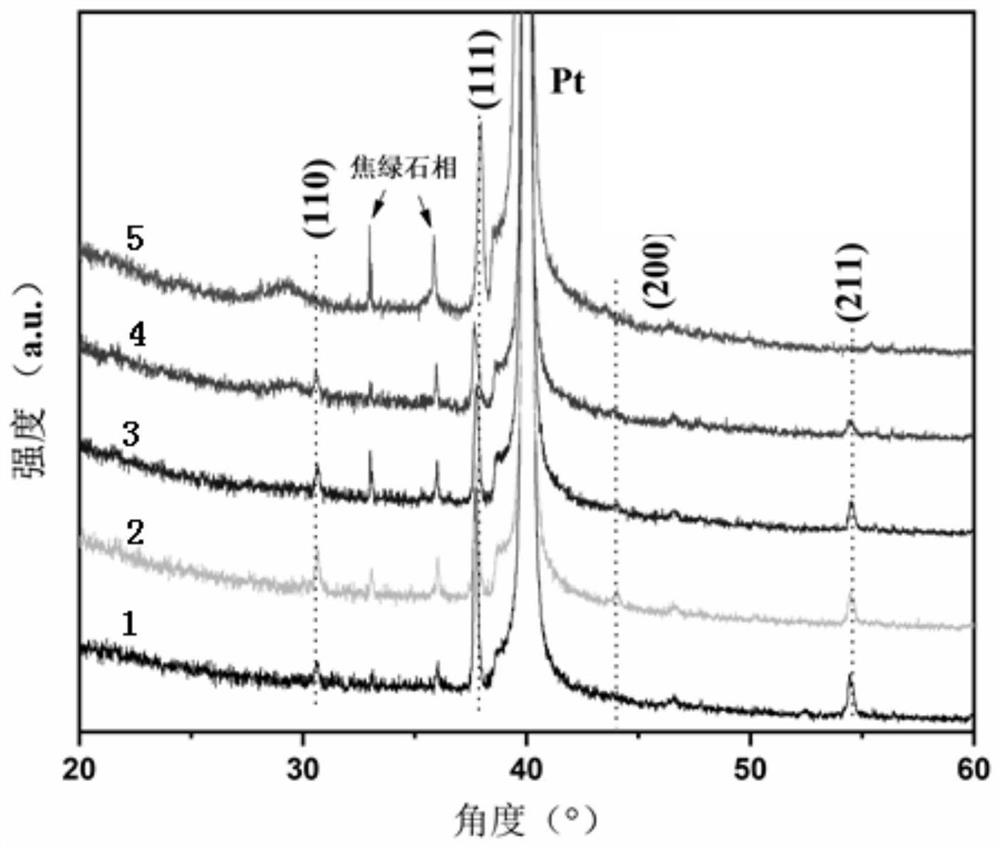

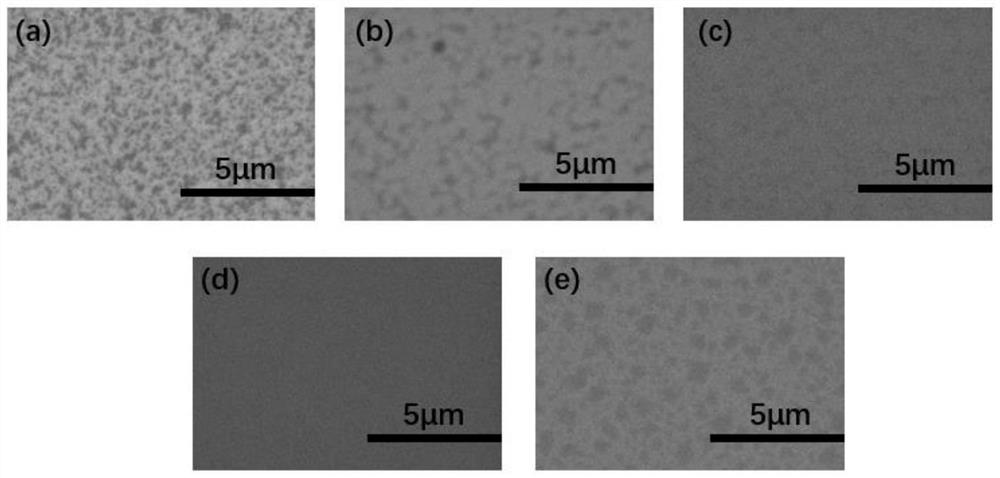

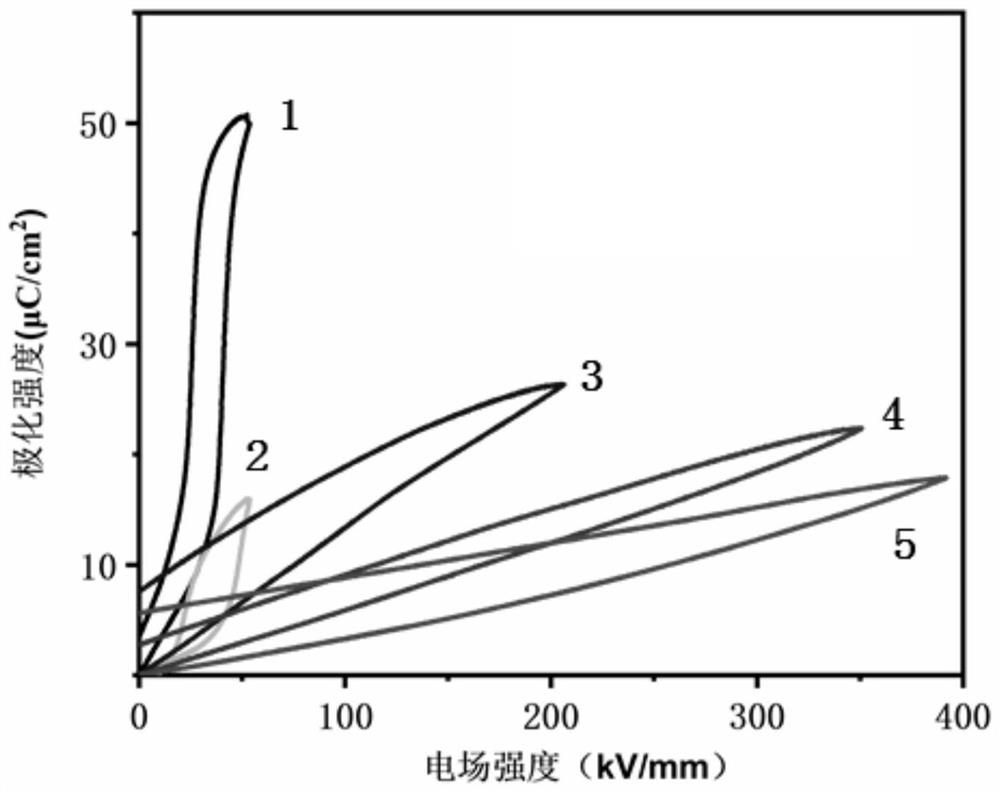

Embodiment 1

[0043] 1. Remove 2.5261g of lead acetate trihydrate (10% excess) in an oven at 125°C for 1 hour to remove crystal water, transfer it to an Erlenmeyer flask, then add 15.3ml of ethylene glycol methyl ether as a solvent, 2ml of acetic acid as a cosolvent, and magnetically Stir at 350r / min for 2h, then cool to room temperature, add 2.7ml of zirconium n-propoxide solution and continue stirring at 350r / min for 2h. Then filter with 0.22 μm pore filter paper and age for 24 hours to obtain 0.3 mol / L lead zirconate sol.

[0044] 2. Pt(111) / Ti / SiO after ultrasonic treatment for 15 minutes, acetone wiping, blast oven drying and heating at 400°C for 3 minutes to remove stress 2 / Si(100) substrate, drop 8-11 drops of the lead zirconate colloid obtained in step 1, and homogenize the colloid at a low speed of 800r / min for 15s, and thin the colloid at a high speed of 4000r / min for 10s to obtain a thickness of 60nm film, and then transfer the film to a flat heater and heat at 400°C for 5min t...

Embodiment 2

[0059] 1. Remove 1.79919 g of lead acetate trihydrate (10% excess) in an oven at 125° C. for 1 hour to remove crystal water, and transfer it to an Erlenmeyer flask. Add 11.6ml of ethylene glycol methyl ether as a solvent, 1ml of acetic acid as a co-solvent, magnetically stir at room temperature at 350r / min for 2h, then cool to room temperature, add 1ml of zirconium n-propoxide solution and 0.7ml of tetrabutyl titanate solution and continue to stir at 350r / min / min speed stirring for 2h. After filtering with 0.22 μm pore filter paper and aging for 24 hours, a 0.3 mol / L PZT sol was obtained.

[0060] 2. Pt(111) / Ti / SiO after ultrasonic treatment for 15 minutes, acetone wiping, blast oven drying and heating at 400°C for 3 minutes to remove stress 2 / Si(100) substrate, drop 8-11 drops of lead zirconate titanate colloid, and uniform glue at 800r / min low speed for 15s, thin the colloid at 4000r / min high speed for 10s, transfer to the flat heater for 400 Heat at ℃ for 5 min to remov...

Embodiment 3

[0064] 1. Remove 2.4755g of lead acetate trihydrate (10% excess) and 0.0520g of lanthanum nitrate in an oven at 125°C to remove crystal water for 1h, transfer them to a conical flask, add 15.3ml of ethylene glycol methyl ether as a solvent, and 2ml of acetic acid as an auxiliary Solvent, magnetically stir at room temperature at 350r / min for 2h, then cool to room temperature, add 2.7ml of zirconium n-propoxide solution and continue stirring at 350r / min for 2h. After filtering with 0.22 μm pore filter paper and aging for 24 hours, a 0.3 mol / L PLZO-2 sol was obtained.

[0065] 2. Pt(111) / Ti / SiO after ultrasonic treatment for 15 minutes in advance, acetone wiping, blast oven drying and heating at 400°C for 3 minutes to remove stress 2 / Si(100) substrate, drop 8-11 drops of lead zirconate colloid, and homogenize the colloid at a low speed of 800r / min for 15s, thin the colloid at a high speed of 4000r / min for 10s, and transfer to a flat heater at 400°C Heat for 5 min to remove solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com