Anti-precipitation aliphatic thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and aliphatic technology, which is applied in the field of anti-separation aliphatic thermoplastic polyurethane elastomer and its preparation, can solve the problems of increasing the molecular weight and length of the chain extender, reducing the physical properties of the final product, and increasing the cost of the chain extender. Precipitation problem, improve the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

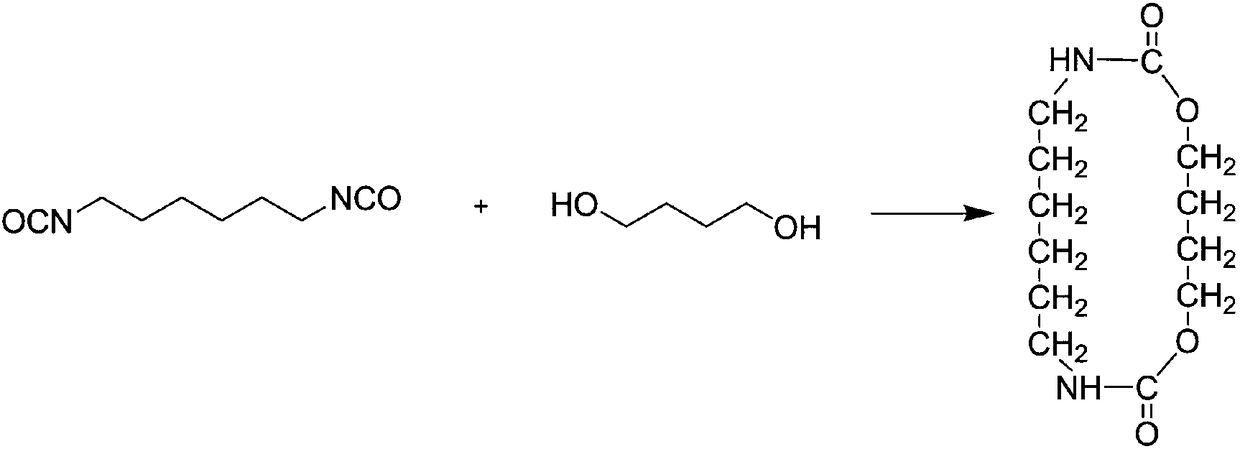

Method used

Image

Examples

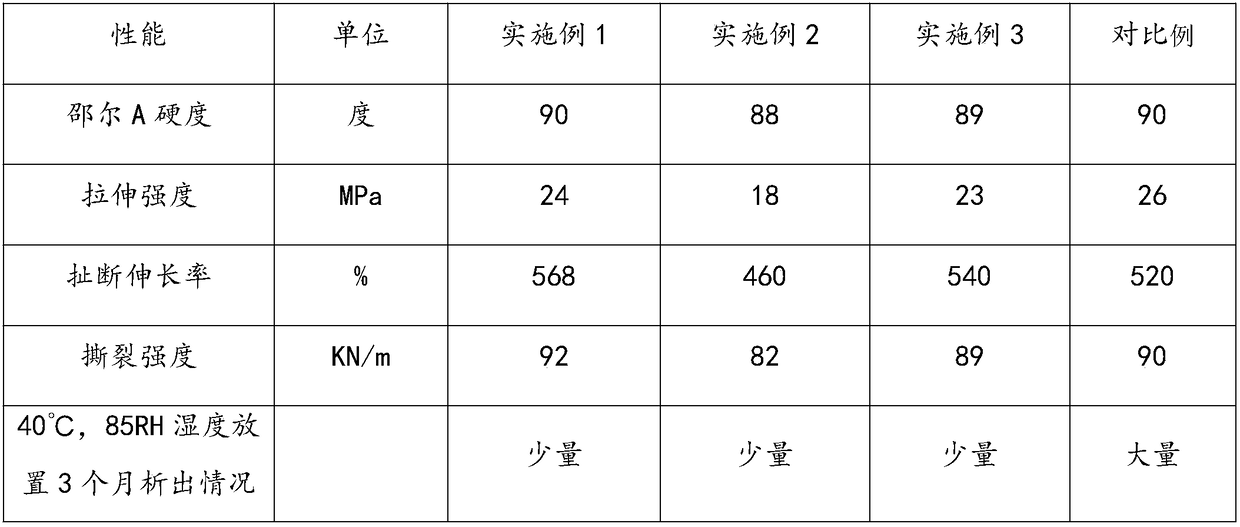

Embodiment 1

[0031] The raw materials are PTMG1000 (polytetrahydrofuran ether glycol, molecular weight 1000), HD I (hexamethylene diisocyanate) and BDO (1,4-butanediol), the molar ratio of HDI and PTMG1000 is 1.8:1, and the R value Set to 1.02 (R value is the molar ratio of isocyanate group to hydroxyl), and the hard segment content is set to 30% (the hard segment content is the total mass of isocyanate and chain extender in the total mass of isocyanate, chain extender and polyol The ratio), dibutyltin dilaurate dosage is 0.03%, antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester) is 0.15%, Antioxidant 264 (2,6-di-tert-butyl-p-cresol) is 0.1%, 2-(2'-hydroxy-3'-5'-di-tert-amylphenyl) benzotriazole is 0.3%, Polyethylene wax is 0.15%. Combine PTMG1000 with dibutyltin dilaurate, antioxidant 1010, antioxidant 264, 2-(2'-hydroxy-3'-5'-di-tert-amylphenyl) benzo The triazole was mixed uniformly to obtain the mixture, which was vacuum dehydrated at 110°...

Embodiment 2

[0033] The raw materials are PCL2000 (polycaprolactone diol, molecular weight 2000), HDI (hexamethylene diisocyanate), BDO (1,4-butanediol), HMDI (dicyclohexylmethane diisocyanate) HDI and HMDI The molar ratio is 4:1, the molar ratio of diisocyanate (HDI, HMDI) to PCL2000 is 1.8:1, the R value is set to 1.02, the hard segment content is set to 30%, and the amount of dibutyltin dilaurate is 0.03% , Antioxidant 1010 (tetra [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester) is 0.15%, antioxidant 264 (2,6-di-tert-butyl pair Cresol) is 0.1%, polyethylene wax is 0.15%, PCL2000 and dibutyltin dilaurate, antioxidant 1010, antioxidant 264 are mixed uniformly to obtain the mixture, vacuum dehydration at 110 ℃ for 3h; pass the casting machine The above mixture is mixed with HD I and HMD I and then injected into the first pouring port of the twin-screw reactive extruder, and BDO is injected into the second pouring port (the seventh zone), and the temperature of e...

Embodiment 3

[0035] The raw materials are PCL2000 (polycaprolactone diol, molecular weight 2000), HD I (hexamethylene diisocyanate), BDO (1,4-butanediol) and MPO (1,3-butanediol), HD The molar ratio of I and PCL2000 is 1.8:1, the mass ratio of BDO to MPO is 4:1, the R value is set to 1.02, the hard segment content is set to 30%, the amount of dibutyltin dilaurate is 0.03%, and the Oxygen agent 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester) is 0.15%, antioxidant 264 (2,6-di-tert-butyl-p-cresol ) Is 0.1%, 2-(2'-hydroxy-3'-5'-di-tert-amylphenyl) benzotriazole is 0.3%, polyethylene wax is 0.15%, and PCL2000 is combined with dibutyltin dilaurate , Antioxidant 1010, Antioxidant 264, 2-(2'-hydroxy-3'-5'-di-tert-amylphenyl) benzotriazole are mixed uniformly to obtain the mixture, and vacuum dehydration at 110℃ for 3h; The above mixture is mixed with HD I through a casting machine and then injected into the first pouring port of the twin-screw reactive extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com