Preparation method of reduced graphene oxide/manganese ferrite nano-composite wave absorbing material

A nano-composite material, manganese ferrite technology, applied in chemical instruments and methods, other chemical processes, magnetic/electric field shielding, etc. Excellent, improve the effect of interface polarization relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Take a 150mL beaker, add 30mL deionized water and 10mL GO water dispersion with a concentration of 2mg / mL. Vigorously stir for 2h, ultrasonic for 30min.

[0028] 2. Add 0.4mmol ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 0.2 mmol manganous chloride tetrahydrate (MnCl 2 4H 2 O), vigorously stirred for 90min.

[0029] 3. Add ammonia water drop by drop to adjust the pH of the mixed dispersion to 11, and then vigorously stir for 10 minutes.

[0030] 4. Pour the mixed dispersion into a 50mL reactor, and conduct a hydrothermal reaction at 180°C for 24 hours.

[0031] 5. After the reaction, cool to room temperature, repeat centrifugation and wash with water for several times to make the pH of the product reach neutral.

[0032] 6. Put it into a vacuum drying oven, dry at 40°C for 24 hours, and grind to obtain the final product, which is designated as S1.

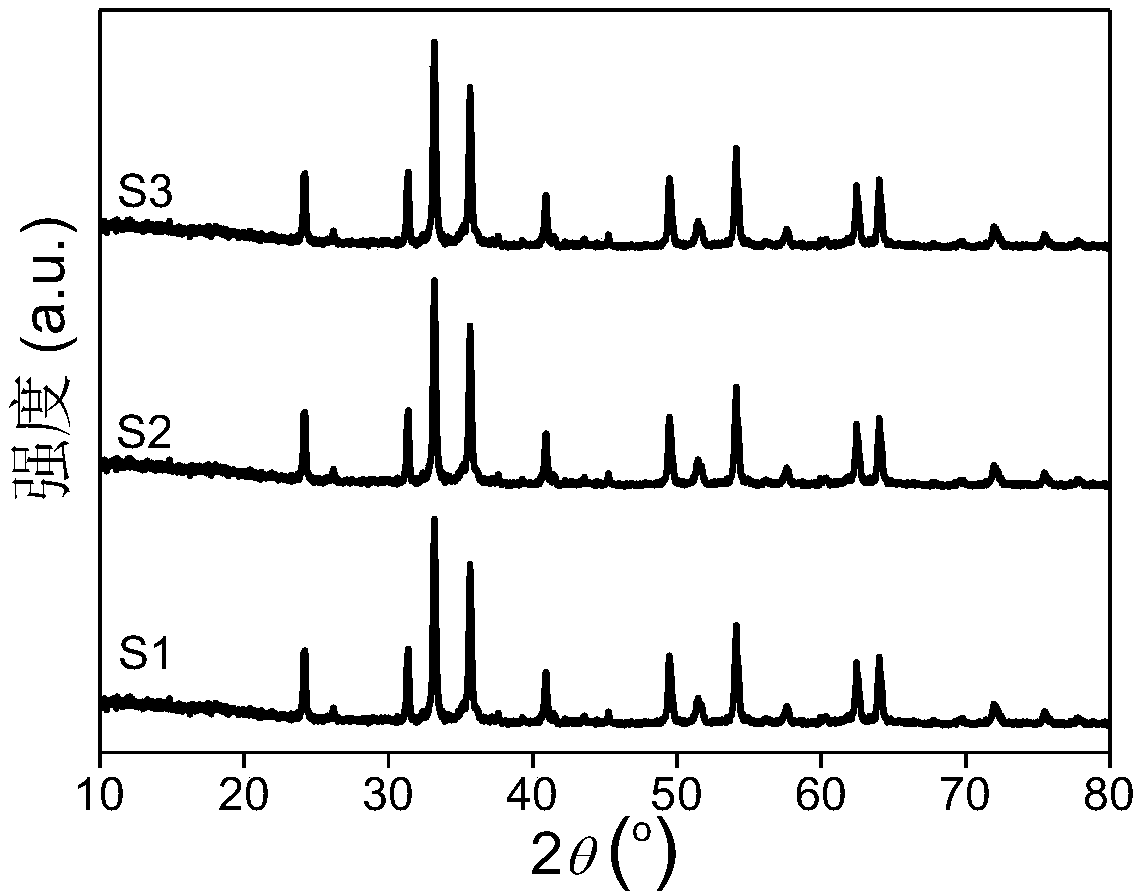

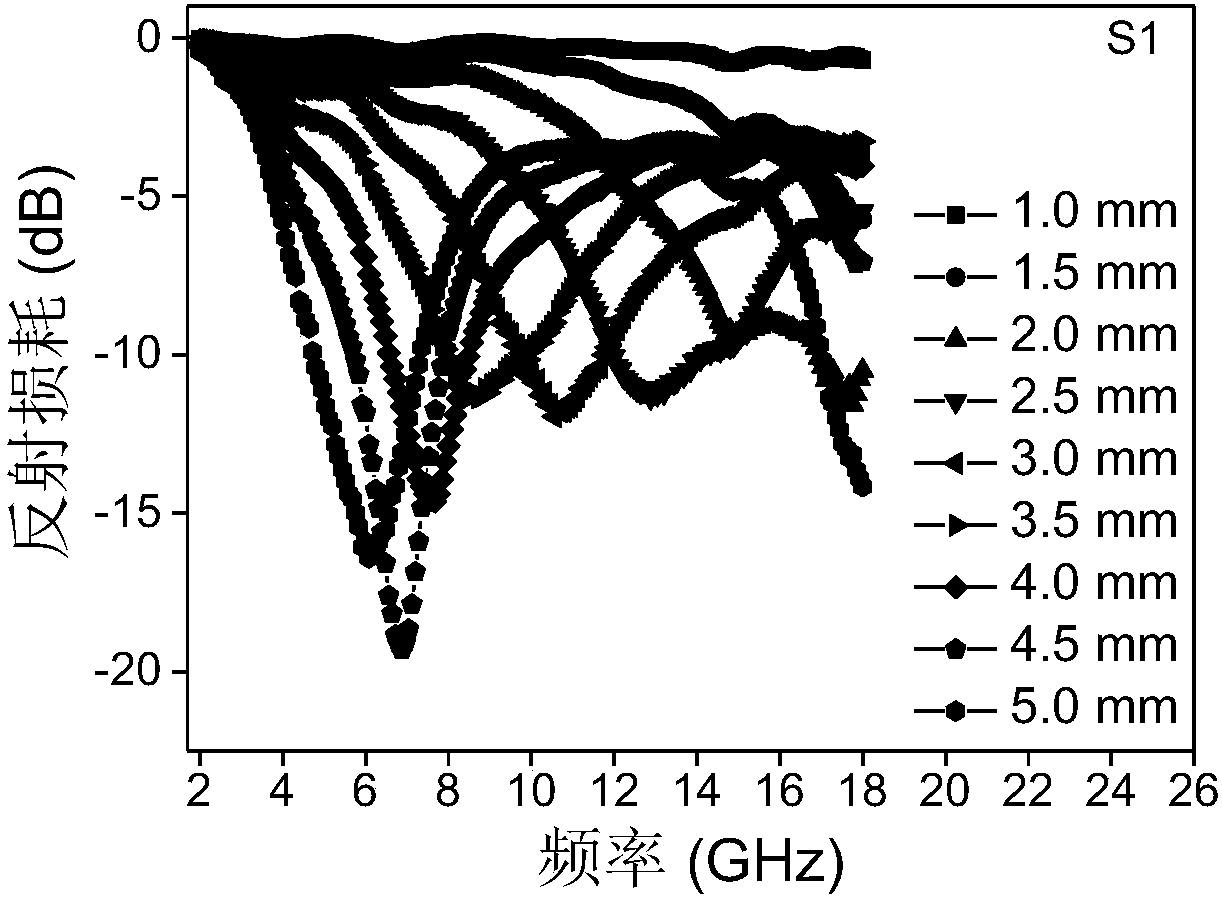

[0033] The XRD spectrogram of embodiment 1 product sees figure 1 . The powder product and paraffin in...

Embodiment 2

[0035] 1. Take a 150mL beaker, add 30mL deionized water and 10mL GO water dispersion with a concentration of 2mg / mL. Vigorously stir for 2h, ultrasonic for 30min.

[0036] 2. Add 0.8mmol ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 0.4 mmol manganous chloride tetrahydrate (MnCl 2 4H 2 O), vigorously stirred for 90min.

[0037] 3. Add ammonia water drop by drop to adjust the pH of the mixed dispersion to 11, and then vigorously stir for 10 minutes.

[0038] 4. Pour the mixed dispersion into a 50mL reactor, and conduct a hydrothermal reaction at 180°C for 24 hours.

[0039] 5. After the reaction, cool to room temperature, repeat centrifugation and wash with water for several times to make the pH of the product reach neutral.

[0040] 6. Put it into a vacuum drying oven, dry at 40°C for 24 hours, and grind to obtain the final product, which is designated as S2.

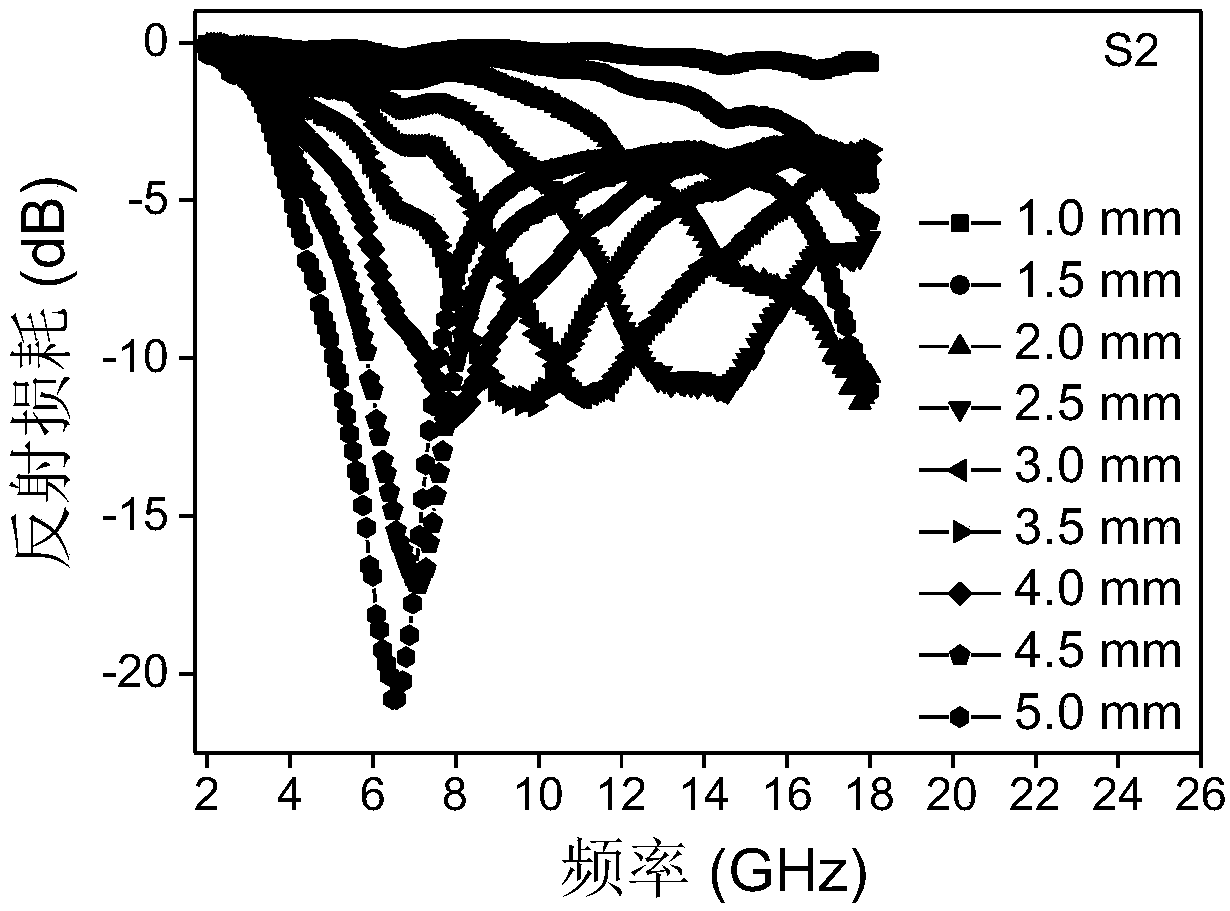

[0041] The XRD spectrum pattern of embodiment 2 product sees figure 1 . The powder product and paraff...

Embodiment 3

[0043]1. Take a 150mL beaker, add 30mL deionized water and 10mL GO water dispersion with a concentration of 2mg / mL. Vigorously stir for 2h, ultrasonic for 30min.

[0044] 2. Add 1.2mmol ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and 0.6 mmol manganous chloride tetrahydrate (MnCl 2 4H 2 O), vigorously stirred for 90min.

[0045] 3. Add ammonia water drop by drop to adjust the pH of the mixed dispersion to 11, and then vigorously stir for 10 minutes.

[0046] 4. Pour the mixed dispersion into a 50mL reactor, and conduct a hydrothermal reaction at 180°C for 24 hours.

[0047] 5. After the reaction, cool to room temperature, repeat centrifugation and wash with water for several times to make the pH of the product reach neutral.

[0048] 6. Put it into a vacuum drying oven, dry at 40°C for 24 hours, and grind to obtain the final product, which is designated as S3.

[0049] The XRD spectrum pattern of embodiment 3 product sees figure 1 . The powder product and paraffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com