Capsule essence and method for preparing capsule essence

A technology of essence and capsules, which is applied in the field of skin care, can solve the problems of users' hand fractures and scratches, and achieve good skin care effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A capsule essence, prepared according to the formula given in Table 1.

[0046]

[0047] processing methods:

[0048] (1) Put the weighed water, hydroxydecyl ubiquinone and alkyl glucoside in a 100ml beaker (container A);

[0049] (2) Continuously homogenize container A at a low shear rate (200-300rpm) for 3-5 minutes;

[0050] (3) Mix the weighed water, butylene glycol, dipropylene glycol, methyl gluceth-20, bio-glucose gum-1, isopentyl glycol, hydrolyzed yeast protein, nicotinamide, sugar Isomers, sodium hyaluronate cross-linked polymer, 1,2-pentanediol, glycerin, soybean isoflavones, collagen, purslane (PORTULACA OLERACEA) extract, α-arbutin, glutathione , palmitoyl tripeptide-5, 1,2-hexanediol, sodium ascorbyl phosphate, palmitoyl oligopeptide, palmitoyl tetrapeptide-7, twisted cactus (OPUNTIASTREPTACANTHA) stem extract, yeast fermentation product extract, fir Caulerpa Taxifolia (CAULERPA TAXIFOLIA) extract, hydrolyzed rice protein, white fungus (TREMELLA FUCI...

Embodiment 2

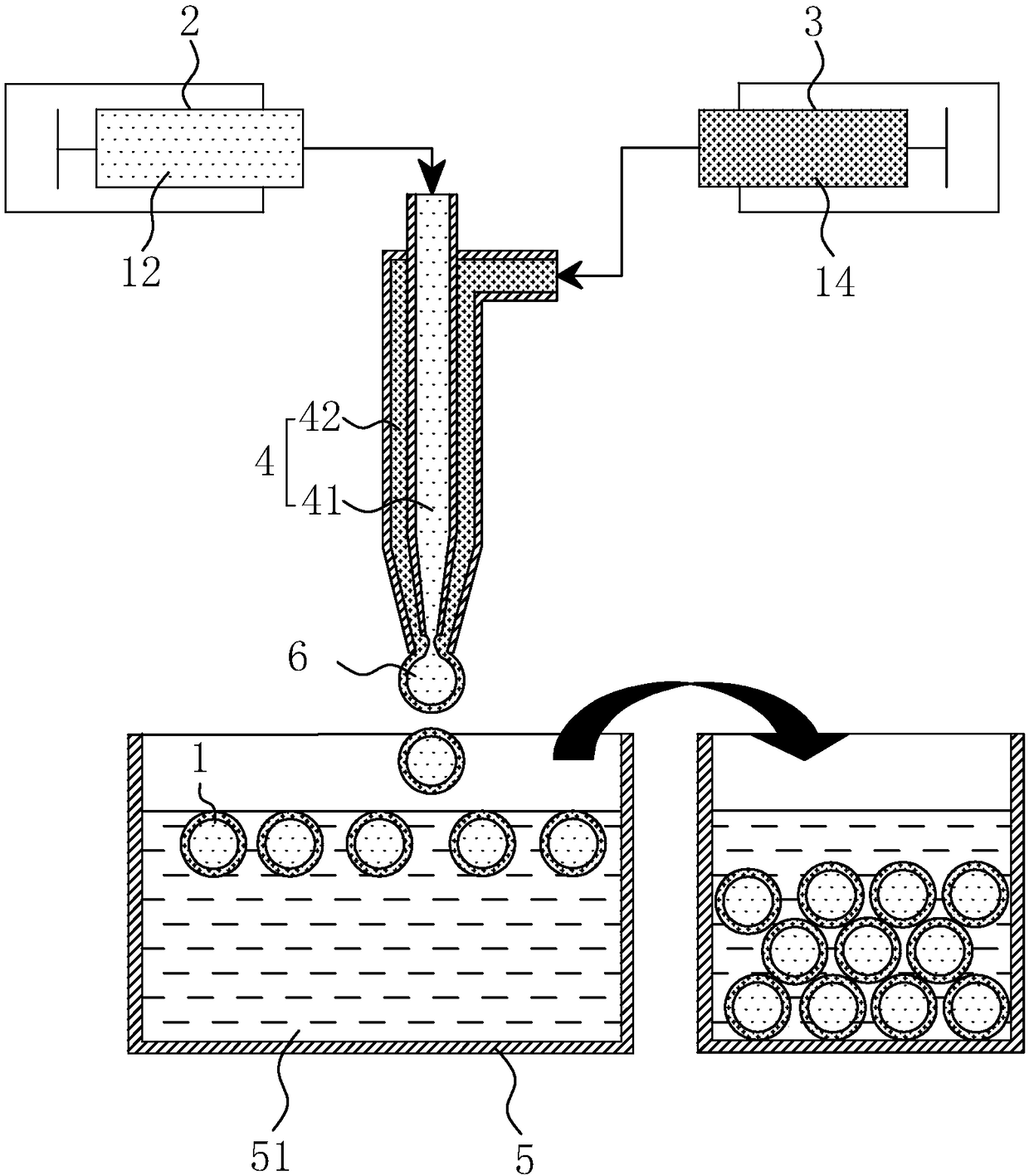

[0069] A method of making a capsule essence, such as Figure 5 As shown, the difference from Embodiment 1 is that it includes a pipeline 8 connected with several double-layer droppers 4 . Wherein, the pipeline 8 includes a first pipeline 81 and a second pipeline 82, the liquid inlet of the first pipeline 81 is connected with the first liquid pump, and the liquid outlet of the first pipeline 81 is connected with the inner dropper 41 The liquid inlet of the second pipeline 82 links to each other with the second liquid pump, and the liquid outlet of the second pipeline 82 links to each other with the outer layer dropper 42 (wherein the first liquid pump and the second liquid pump are not drawn on the figure ).

[0070] The advantage of the method is that the capsule essence can be produced in batches, thereby improving production efficiency and reducing production cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com