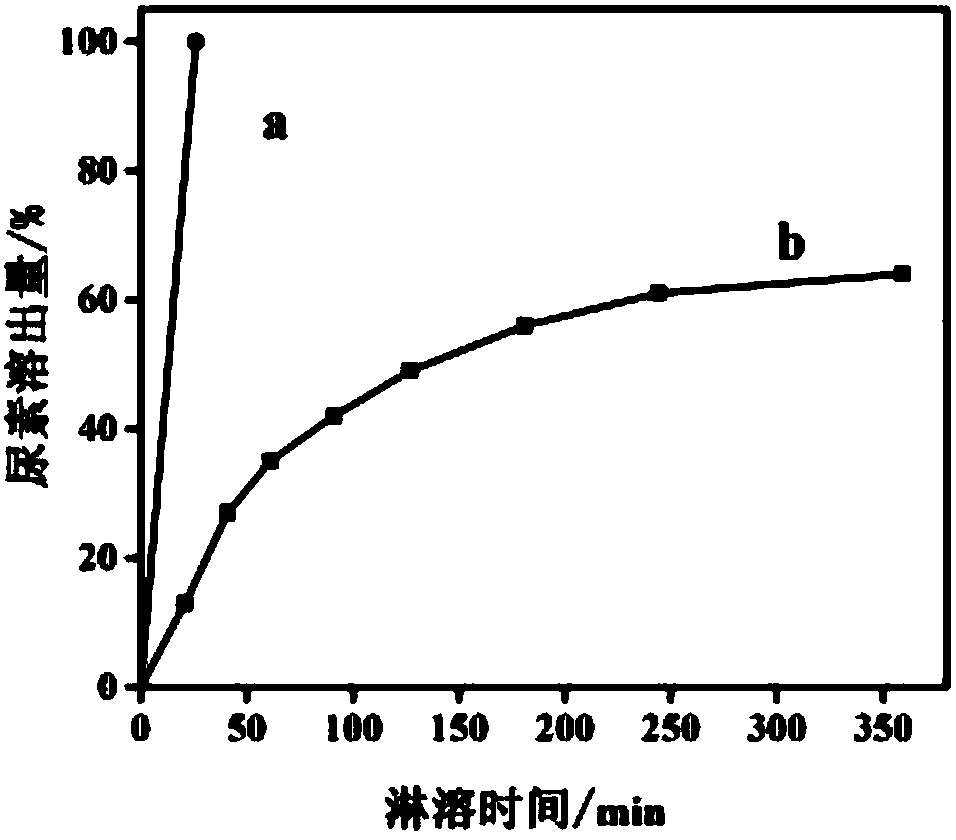

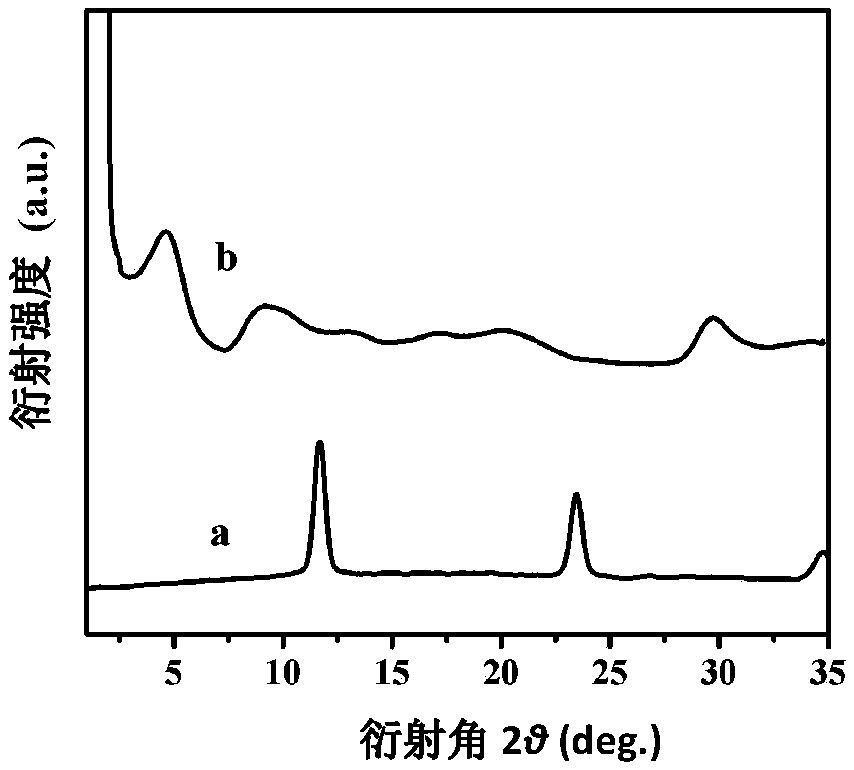

Preparation method of fertilizer with functions of reducing content of heavy metal ions and achieving sustained release

A technology of heavy metal ions and slow-release fertilizers, applied in the field of slow-release fertilizers, can solve the problems of application limitation, high cost, long time consumption, etc., and achieve the effects of cost saving, less loss and strong economic advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Sodium sulfide (0.5 g) and polyvinyl alcohol 400 (50 g) were added to water (500 g) in turn, and stirred for 40 min to mix the compounds uniformly to form solution A.

[0038] Then, aluminum nitrate nonahydrate (2.6g) and magnesium nitrate hexahydrate (3.2g) were added to water (45g) from which carbon dioxide was removed to form a mixed solution. The mixed solution was stirred and adjusted to pH 7.0 with 5wt% NaOH, and the mixed solution was placed at 70 ℃, react under nitrogen protection for 2h, and filter out colloidal substance B.

[0039] Then, the solution A and the filtered colloidal substance B were uniformly mixed at a weight ratio of 1:1, placed at 50 °C, and stirred for 5 h to obtain a colloidal solution C.

[0040] Then, C and lignin were uniformly mixed at a weight ratio of 10:1, placed at 20 °C, and stirred for 1 h to obtain D.

[0041] Finally, D and urea were mixed in a weight ratio of 11:2, placed at 60°C, stirred for 3 hours, dried at 65°C for 10 hours,...

Embodiment 2

[0043] Sodium sulfide (0.8 g) and polyvinyl alcohol 600 (80 g) were added to water (600 g) in turn, and stirred for 40 min to mix the compounds uniformly to form solution A. Then, aluminum nitrate nonahydrate (2.8g) and magnesium nitrate hexahydrate (3.9g) were added to water (50g) from which carbon dioxide was removed to form a mixed solution. The mixed solution was stirred and adjusted to pH 8.0 with 10wt% NaOH, and the mixed solution was placed at 70 ℃, react under nitrogen protection for 10 h, and filter out the colloidal substance B. Then, the solution A and the filtered colloidal substance B were uniformly mixed at a weight ratio of 2:1, placed at 60°C, and stirred for 8 h to obtain a colloidal solution C. Then, C and lignin were uniformly mixed at a weight ratio of 15:1, placed at 50 °C, and stirred for 5 h to obtain D. Finally, D and urea were mixed in a weight ratio of 8:1, placed at 80°C, stirred for 6 hours, dried at 65°C for 10 hours, crushed and sieved, and 10-20...

Embodiment 3

[0045] Sodium sulfide (1.4 g) and polyvinyl alcohol 1000 (40 g) were successively added to water (350 g), and stirred for 10 min to mix the compounds uniformly to form solution A. Then, aluminum nitrate nonahydrate (3.1 g) and magnesium nitrate hexahydrate (3.7 g) were added to water (65 g) from which carbon dioxide was removed to form a mixed solution, and the mixed solution was stirred while adjusting the pH to 7.5 with 15wt% NaOH, and the mixed solution was placed at 75 ℃, react under nitrogen protection for 6 h, and filter out the colloidal substance B. Then, the solution A and the filtered colloidal substance B were uniformly mixed at a weight ratio of 3:1, placed at 55° C., and stirred for 7 h to obtain a colloidal solution C. Then, C and lignin were uniformly mixed at a weight ratio of 35:2, placed at 40 °C, and stirred for 10 h to obtain D. Finally, D and urea were mixed in a weight ratio of 11:4, placed at 25°C, stirred for 1 hour, dried at 65°C for 10 hours, crushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com