Method for preparing epichlorohydrin from dichloropropanol

A technology of epichlorohydrin and dichloropropanol, which is applied in the chemical industry to achieve the effects of avoiding by-product salt and waste water, strong selectivity, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

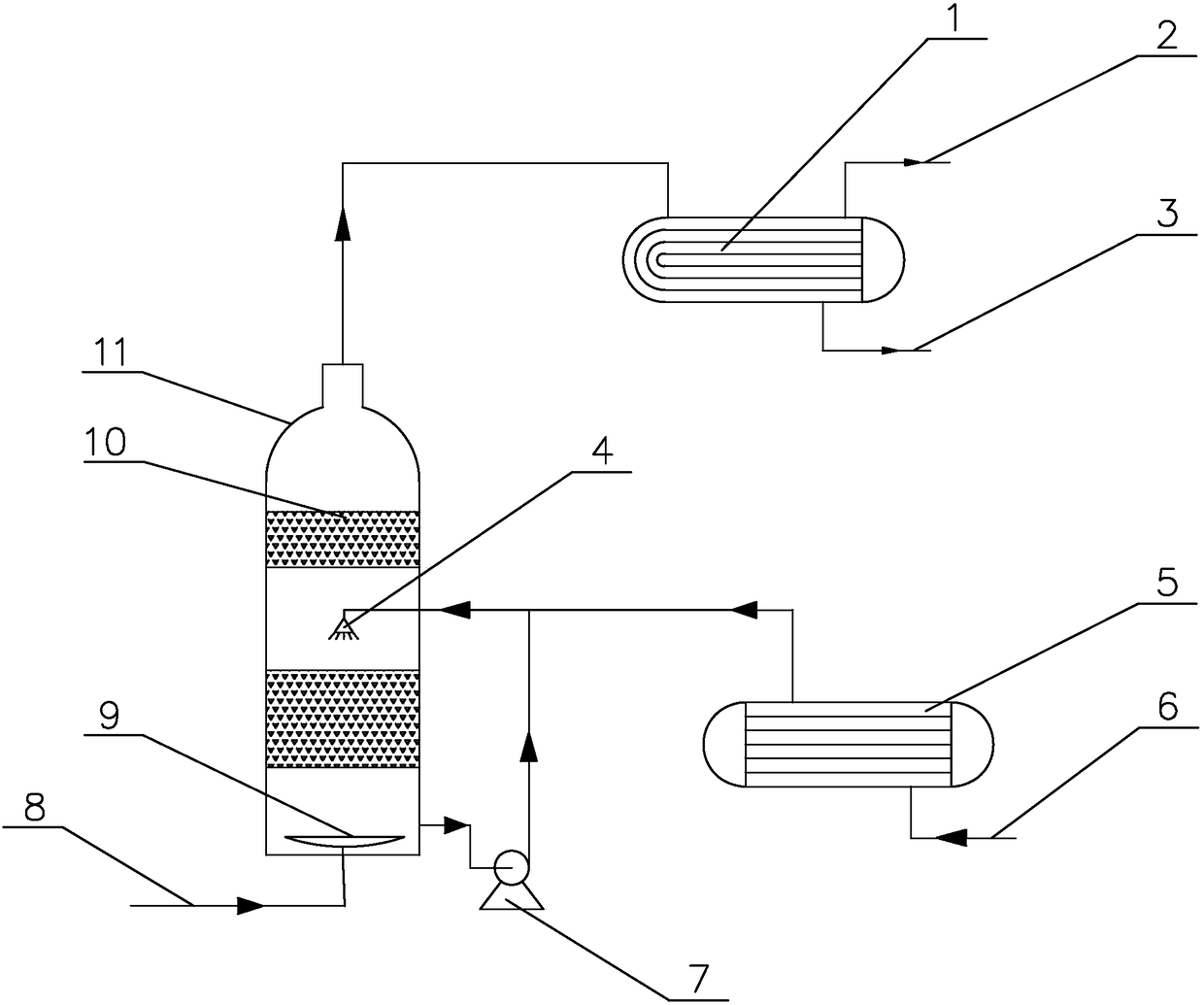

Method used

Image

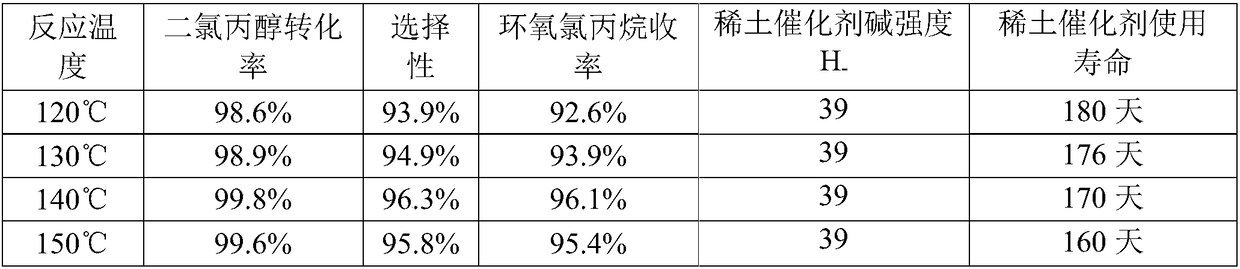

Examples

Embodiment 1

[0035] (1) Preparation of rare earth catalyst CeO 2 / Na 2 O / γ-Al 2 o 3

[0036] First weigh 25.4g of cerium carbonate, 51.3g of sodium carbonate, and 180.0g of aluminum isopropoxide, mix them, add 200.0g of water, mix and stir at room temperature, and cut evenly with a shearing machine. , and the outlet temperature is 90°C for spray molding to obtain a spray material;

[0037] Weigh 140.0g of the spray material obtained above, put it into a dry mixer and stir for 10 minutes, continue to weigh 1.0g of glass fiber chopped strands, 5.0g of yellow dextrin, 5.0g of polyvinyl alcohol, 2.5g of water, 20.0g of aluminum The sol was sequentially added into the dry mixer according to the above order and mixed and stirred for 15 minutes to obtain the wet mixed material. Put the wet mixed material through the mud trainer to practice the mud, squeeze out the mud section, put it into a material bucket with a plastic bag, and practice the mud twice; put the mud section that has been trai...

Embodiment 2

[0044] (1) Preparation of rare earth catalyst Pr 2 o 3 / K 2 O / ZnO

[0045] First weigh 27.1g of praseodymium carbonate, 51.4g of potassium carbonate, and 135.2g of zinc carbonate, mix them, add 178.4g of water, mix and stir at room temperature, and cut evenly with a shearing machine. Spray molding at a temperature of 90°C to obtain a spray material;

[0046] Weigh 138.0g of the spray material obtained above and put it into a dry mixer and stir for 10 minutes, continue to weigh 2.0g of glass fiber chopped strands, 5.0g of polyvinyl alcohol, 25g of glycerin, and 30.0g of saccharin, and add dry Mix and stir in a mixer for 15 minutes to obtain a wet mixed material. Put the wet mixed material through the mud trainer to practice the mud, squeeze out the mud section, put it into a material bucket with a plastic bag, and practice the mud twice; put the mud section that has been trained twice into the hydraulic extruder to filter, and A 6-mesh filter screen is installed at the ext...

Embodiment 3

[0053] (1) Preparation of Rare Earth Catalyst La 2 o 3 / K 2 O / γ-Al 2 o 3

[0054] First weigh 26.7g of lanthanum carbonate, 36.7g of potassium carbonate, and 78.4g of pseudo-boehmite, mix them, add 98.6g of water, mix and stir at normal temperature, after shearing evenly with a shearing machine, the temperature at the inlet of the spray tower is 280 ℃, and the outlet temperature is 90 ℃, and the spray molding is obtained to obtain the spray material;

[0055] Weigh 135.0g of the spray material obtained above and put it into a dry blender and stir for 15 minutes, continue to weigh 1.0g of glass fiber chopped strands, 18.0g of water, and 15.0g of aluminum sol, and add them to the dry blender in order to mix Stir for 15 minutes to obtain a wet mix. Put the wet mixed material through the mud trainer to practice the mud, squeeze out the mud section, put it into a material bucket with a plastic bag, and practice the mud twice; put the mud section that has been trained twice in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com