A kind of preparation method and product thereof of elastic cross-linked water-resistant polyurethane-modified polyacrylate emulsion

A technology of polyacrylate emulsion and polyurethane modification, applied in the field of polyurethane modified polyacrylate polymer emulsion, can solve the problems of poor adjustability, reduced water resistance of material film, formaldehyde release, etc., to improve flexibility and extensibility , the effect of eliminating the reduction of water resistance and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

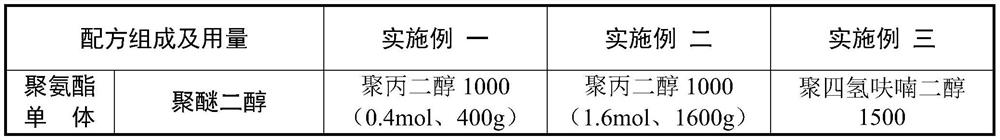

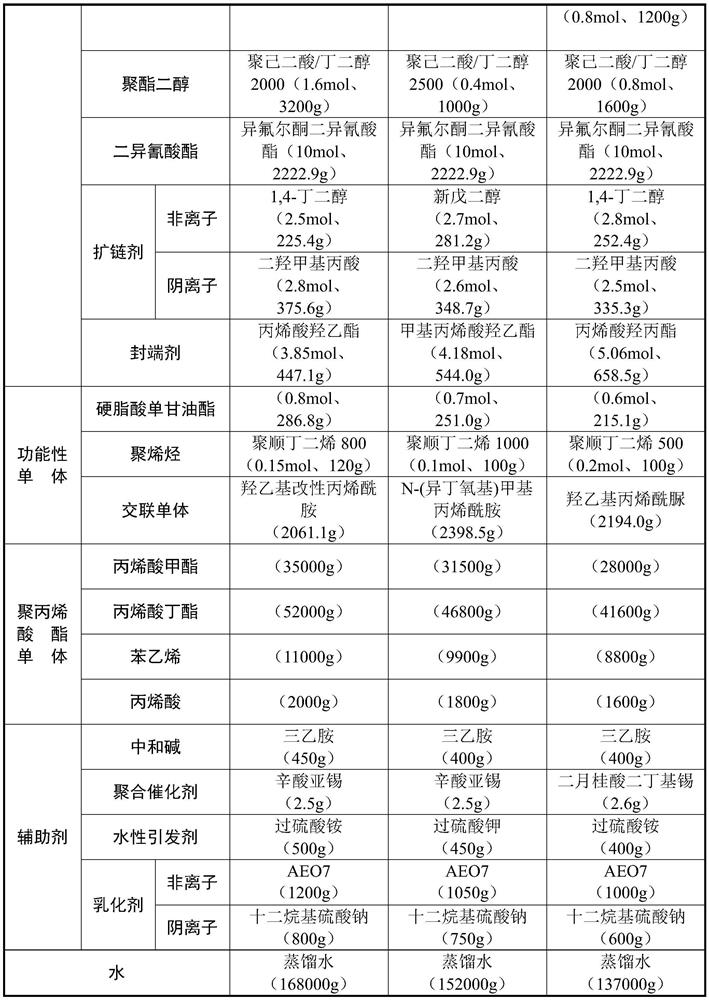

Embodiment 1

[0070] Embodiment 1 The preparation method of the water immersion resistant polyurethane modified polyacrylate emulsion with elastic crosslinking of the present invention

[0071] The concrete steps of this preparation method:

[0072] (1) The step of bulk polymerization, which reacts polyether diol, polyester diol, diisocyanate, chain extender, monoglyceride stearate, polyolefin, and polymerization catalyst to obtain a polyurethane prepolymer; Specifically:

[0073] (1.1) Put polyether diol, polyester diol, monoglyceride stearate, polyolefin, chain extender, and diisocyanate into the reaction device, heat to 75°C, stir and keep warm for 30 minutes;

[0074] (1.2) Add a polymerization catalyst to the system in step (1.1), control the temperature to 85° C., stir and keep warm for 100 minutes to prepare a polyurethane prepolymer.

[0075] (2) the step of capping, this step reacts polyurethane prepolymer and capping agent, makes polyurethane active monomer; Be specifically:

...

Embodiment 2

[0092] Embodiment 2 The preparation method of the water immersion resistant polyurethane modified polyacrylate emulsion with elastic crosslinking of the present invention

[0093] The concrete steps of this preparation method:

[0094] (1) The step of bulk polymerization, which reacts polyether diol, polyester diol, diisocyanate, chain extender, monoglyceride stearate, polyolefin, and polymerization catalyst to obtain a polyurethane prepolymer; Specifically:

[0095] (1.1) Put polyether diol, polyester diol, monoglyceride stearate, polyolefin, chain extender, and diisocyanate into the reaction device, heat to 70°C, stir and keep warm for 40 minutes;

[0096] (1.2) Add a polymerization catalyst to the system in step (1.1), control the temperature at 80-85° C., stir and keep warm for 120 minutes to prepare a polyurethane prepolymer.

[0097] (3) The step of capping, this step reacts polyurethane prepolymer and capping agent, makes polyurethane active monomer; Be specifically: ...

Embodiment 3

[0113] Embodiment 3 The preparation method of the water immersion resistant polyurethane modified polyacrylate emulsion with elastic crosslinking of the present invention

[0114] The concrete steps of this preparation method:

[0115] (1) The step of bulk polymerization, which reacts polyether diol, polyester diol, diisocyanate, chain extender, monoglyceride stearate, polyolefin, and polymerization catalyst to obtain a polyurethane prepolymer; Specifically:

[0116] (1.1) Put polyether diol, polyester diol, monoglyceride stearate, polyolefin, chain extender, and diisocyanate into the reaction device, heat to 75-80°C, stir and keep warm for 20 minutes;

[0117] (1.2) Add a polymerization catalyst to the system in step (1.1), control the temperature at 85-90° C., stir and keep warm for 80 minutes to prepare a polyurethane prepolymer.

[0118] (4) The step of capping, this step reacts polyurethane prepolymer and capping agent, makes polyurethane active monomer; Be specifically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com