Water-based solid electrolyte membrane, preparation method thereof, and secondary battery

A technology of solid electrolyte membrane and solid electrolyte, applied in secondary batteries, electrolyte immobilization/gelation, circuits, etc., can solve the problems of high cost and poor safety, achieve uniform thickness, good high temperature resistance, liquid absorption good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

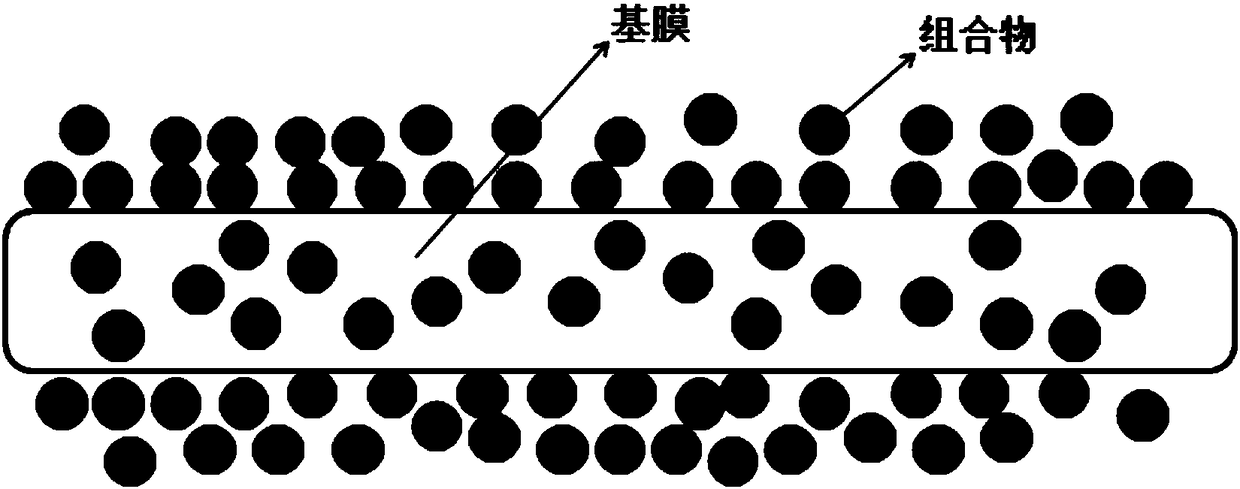

[0055] This embodiment provides a water-based solid electrolyte membrane, comprising a base film and a water-based solid electrolyte layer composed of a coating slurry coated on one side of the base film, wherein the base film is a polypropylene porous film with a thickness of 10um, and a single The surface coating method, the coating thickness is 2um, and the coating slurry used to form the water-based solid electrolyte layer is according to the mass ratio: 20% of the composition, 80% of deionized water; wherein, the preparation of the composition is according to the mass ratio: nano Lithium Titanium Aluminum Phosphate Lithium Solid Electrolyte 1.5 al 0.5 Ti 1.5 (PO 4 ) 3 Powder 97%, particle size D50 is 200nm, binder sodium carboxymethyl cellulose 1%, binder styrene-butadiene latex 1%, dispersant sodium polyacrylate 1%, additive octylphenol polyoxyethylene 1% .

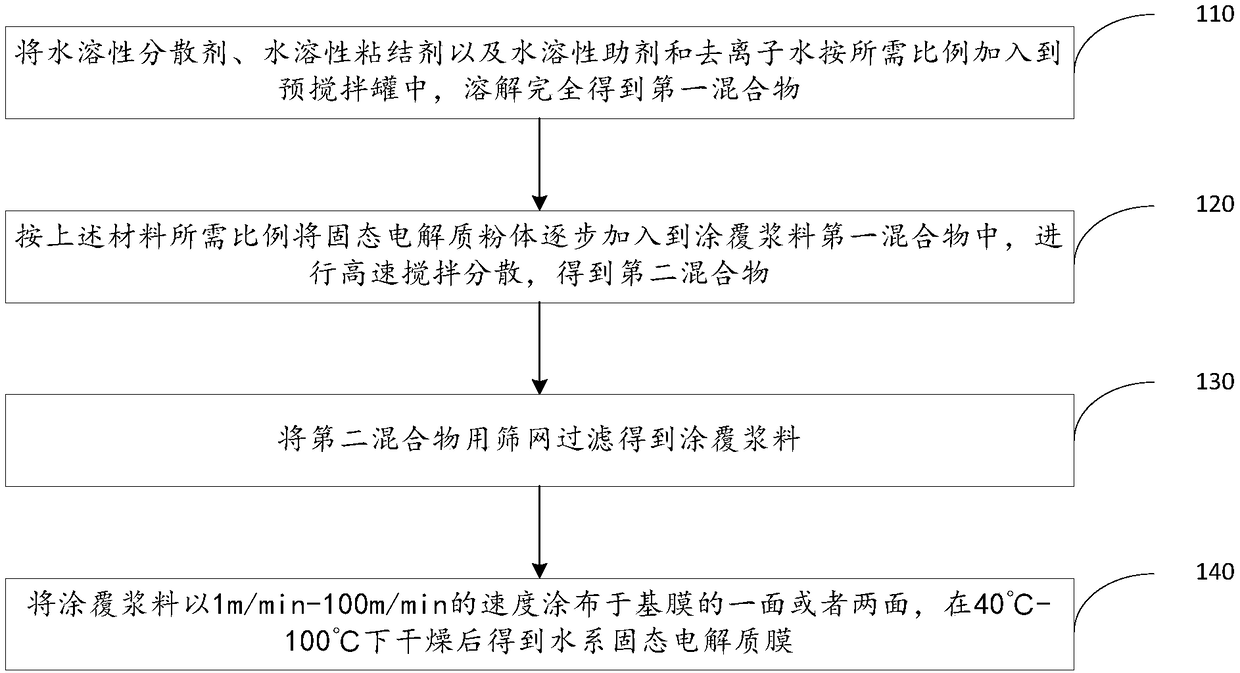

[0056] The aqueous solid electrolyte membrane in this example is prepared by the following method, which spe...

Embodiment 2

[0064] This embodiment provides a water-based solid electrolyte ceramic membrane, which includes a base membrane and a water-based solid electrolyte layer composed of a coating slurry coated on one side of the base membrane. The base film is a polypropylene porous film with a thickness of 7um. It is coated on one side with a thickness of 2um. The coating slurry used to form the water-based solid electrolyte layer is: 20% composition, 80% deionized water %; wherein, the preparation of the composition is according to the mass ratio: nanometer solid electrolyte lithium titanium aluminum phosphate Li 1.5 al 0.5 Ti 1.5 (PO 4 ) 3 Powder 96%, particle size D50 is 200nm, binder sodium carboxymethyl cellulose 1%, binder styrene-butadiene latex 1%, dispersant 1% sodium dodecyl sulfate, additive octylphenol polyoxygen Ethylene 0.5%, polyvinyl alcohol 0.5%.

[0065] The method for preparing the water-based solid electrolyte membrane is the same as in Example 1, except that the coatin...

Embodiment 3

[0067] This embodiment provides a water-based solid electrolyte membrane, comprising a base membrane and a water-based solid electrolyte coating composed of a coating slurry coated on one side of the base membrane, wherein the base membrane is a polypropylene porous membrane with a thickness of 7um. Single-sided coating method, the coating thickness is 2um, and the coating slurry used to form the water-based solid electrolyte layer is according to the mass ratio: 20% of the composition, 80% of deionized water; wherein, the preparation of the composition is according to the mass ratio: Nano-solid electrolyte lithium titanium aluminum phosphate Li 1.2 al 0.2 Ti 1.8 (PO 4 ) 3Powder 97%, particle size D50 is 200nm, binder sodium carboxymethyl cellulose 1%, binder styrene-butadiene latex 1%, dispersant polyethylene glycol 0.2%, dispersant sodium lignosulfonate 0.6%, Auxiliary fluorocarbon surfactant 0.2%.

[0068] The method for preparing the water-based solid electrolyte memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com