Process for preparing tert-butylamine in dynamic equilibrium of raw materials

A technology of dynamic balance and tert-butylamine, which is applied in the preparation of amino compounds, organic compounds, chemical instruments and methods, etc. It can solve the problems of enhanced alkalinity, harsh requirements for reaction devices, and large pressure fluctuations, and achieve stable performance and low price. , the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

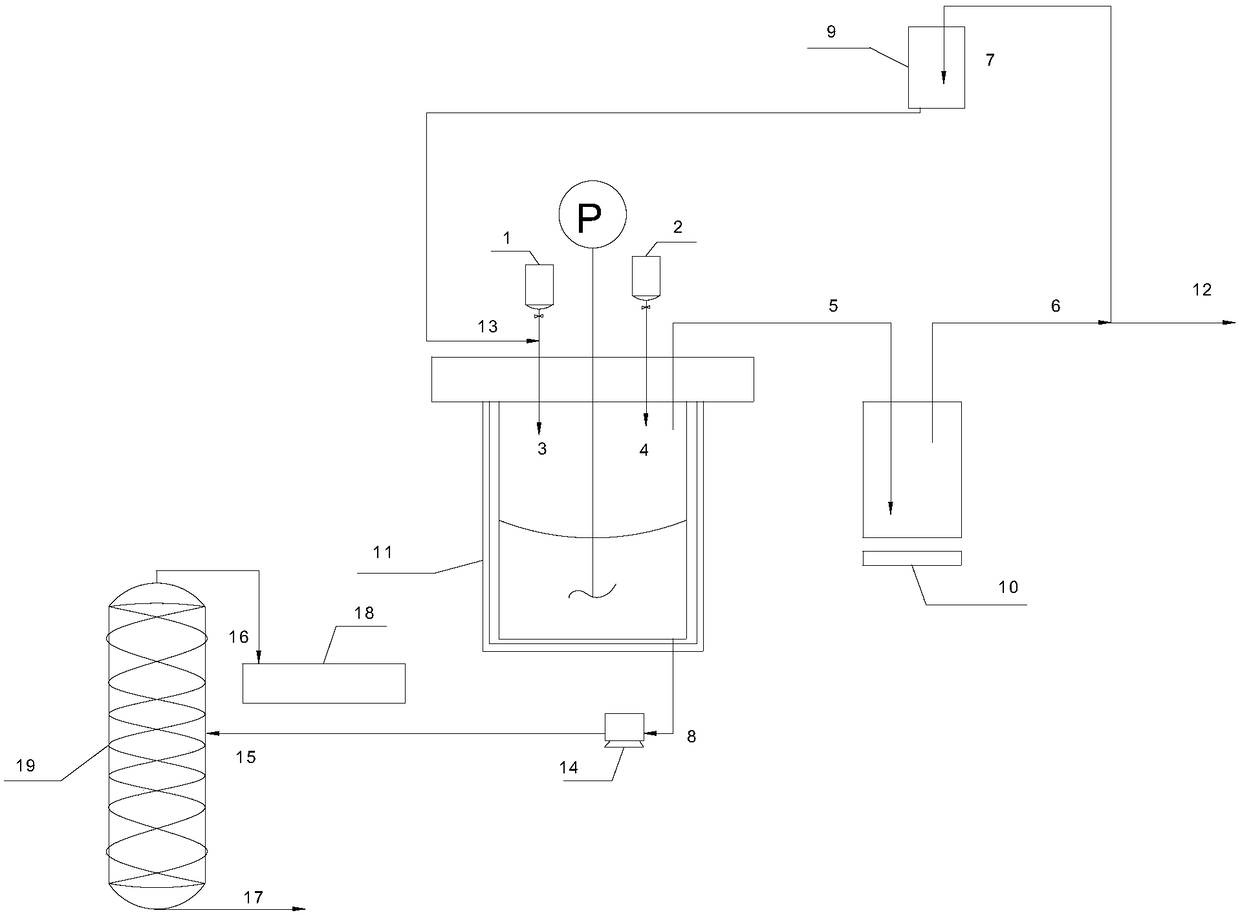

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 (using non-molecular sieve type aluminosilicate catalyst)

[0043] Prepare tert-butylamine according to the following method, comprising the following steps:

[0044] (1) Put 29.2990g tert-butanol, liquid ammonia, self-made non-molecular sieve type aluminosilicate catalyst (prepared by the method described in CN106732496A) and isobutylene into the reactor, at a reaction temperature of 275°C and a reaction pressure of 23MPa Reaction 2h; Wherein, the feed molar ratio of tert-butanol and ammonia is 1:3.0, the mass ratio of tert-butanol and catalyst is 5.9:1, and the feed molar ratio of tert-butanol and isobutylene is 1:1.5;

[0045] (2) After the reaction is finished, cool down to room temperature, collect liquid phase substances, and measure and obtain various reaction performance parameters according to the above method.

[0046] In this reaction, the yield of t-butylamine was 2.58%.

Embodiment 2

[0047] Embodiment 2 (using molecular sieve type aluminosilicate catalyst, without isobutylene circulation)

[0048] Prepare tert-butylamine according to the following method, comprising the following steps:

[0049] (1) 39.4940g tert-butanol, liquid ammonia and ZSM-5 molecular sieve powder are put into the reactor, and react for 2h at a reaction temperature of 275°C and a reaction pressure of 23MPa; wherein, the feed molar ratio of tert-butanol and liquid ammonia is 1:3.0, the mass ratio of tert-butanol and ZSM-5 molecular sieve is 7.8:1, and the silicon-aluminum ratio of ZSM-5 molecular sieve is 27;

[0050] (2) After the reaction is finished, cool down to room temperature, collect liquid phase substances, and measure various reaction performance parameters.

[0051] In this reaction, the yield of tert-butylamine was 10.91%.

Embodiment 3

[0052] Embodiment 3 (using molecular sieve type aluminosilicate catalyst, isobutylene recycles)

[0053] Prepare tert-butylamine according to the following method, comprising the following steps:

[0054] (1) Put 18.2210g of tert-butanol, liquid ammonia, ZSM-5 molecular sieve particles and isobutene into the reactor, and react for 3.2h at a reaction temperature of 275°C and a reaction pressure of 17MPa; among them, the feed of tert-butanol and liquid ammonia The molar ratio is 1:3.4, the mass ratio of tert-butanol and ZSM-5 molecular sieve is 4.6:1, the feed molar ratio of tert-butanol and isobutene is 1:1.7, and the silicon-aluminum ratio of ZSM-5 molecular sieve is 25;

[0055] (2) After the reaction is finished, cool down to room temperature, collect liquid phase substances, and measure various reaction performance parameters.

[0056] In this reaction, the yield of tert-butylamine was 11.92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com