Four-component silane modified sealant as well as preparation and use methods thereof

A silane-modified, four-component technology, applied in adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as poor paintability, achieve long service life, reliable and durable sealing and protection performance, Optimize the effect of comprehensive cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

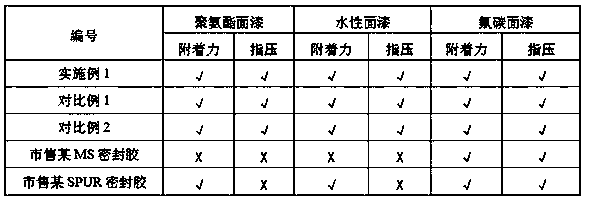

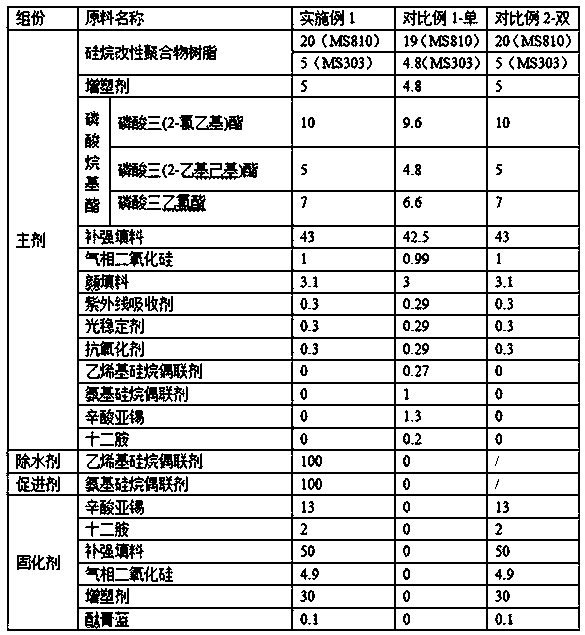

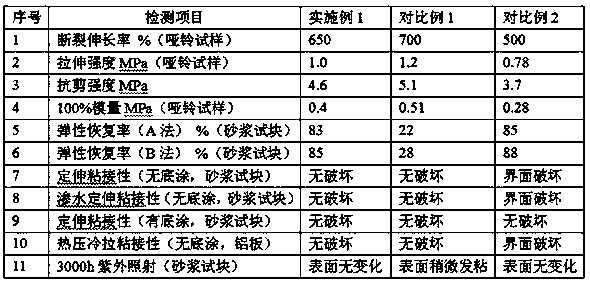

[0054] Table 1 lists a four-component implementation formula component, that is, Example 1. The raw materials used belong to the prior art; at the same time, according to the four-component main agent: dewatering agent: accelerator: curing agent=10:0.03:0.1 : 1 implementation ratio, carry out corresponding ratio design to each component, form single-component comparative example 1 and two-component comparative example 2.

[0055] Silane-modified polymer resins are MS, STP, STPE, SPU, SPUR and other silane-modified polymer resin products of the prior art; plasticizers can be existing DIDI, PPG and other plasticized products; reinforcing fillers are existing There are technical products, preferably nano-calcium carbonate; pigments and fillers are prior art products, such as carbon black, phthalocyanine pigments, titanium dioxide and other pigments, and fillers such as heavy calcium, light calcium, and silicon micropowder; weather resistance additives are prior art products, Such...

Embodiment 2

[0061] The preparation method of the present invention is carried out according to the proportioning component design of Example 1, and the specific method is as follows:

[0062] The preparation method of the main ingredient is: using a double planetary mixer, according to the design of the main ingredient formula, weighing and adding silane-modified polymer resin, plasticizer, alkyl phosphate, reinforcing filler, pigment filler, fumed silica, each For weather-resistant additives, etc., under normal temperature and vacuum conditions, start the double planetary mixer, mix the materials into a uniform and fine paste, and then pack them out, generally in 4L or 20L barrels;

[0063] Preparation method of curing agent: according to the design ratio of curing agent, weigh reinforcing fillers, pigments and fillers, fumed silica and other powders, dry them at 105°C for 2 hours, cool them for later use; then put them in a dry and clean double planetary mixer Add stannous octoate, dode...

Embodiment 3

[0068] Open the main agent 4L barrel cover in the four-component sealant prepared in Example 2, put the barrel on the material disperser, install the stirring paddle, and after the test machine is normal, the dewatering agent can be mixed according to the total weight of the main agent ( 0.3% (about 16.8g) of about 5.6Kg) was added and mixed for 8 minutes; then an accelerator (about 56g) was added according to the weight of the main agent at 1% and dispersed for 6 minutes; finally, a curing agent was added at a ratio of 10% of the total amount of the main agent (about 560g), stop the machine after 8 minutes of dispersion, remove the stirring paddle, then use a glue gun to suck glue or scrape glue with a scraper, and seal and protect the designated position according to the design or use requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com