Method for recovering and extracting lithium

A technology for extracting lithium and organic extractant, applied in the field of lithium recovery and extraction, can solve the problems of co-extraction effect, increased sludge treatment cost, increased post-treatment load, etc., so as to simplify the extraction operation process and avoid hydroxides. The effect of precipitation and reduction of post-processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] a. Add 0.2g of solid sodium hydroxide to 10ml of Cyanex272, stir with a magnet, add 5ml of absolute ethanol and heat to above 50°C for about three hours, wait for the complete evaporation of absolute ethanol (can be determined by comparing with the original oil phase liquid level) Judging volatilization), saponified Cyanex272 was obtained;

[0047] b. Add 2g of solid sodium hydroxide to 50ml of kerosene, stir with a magnet, add 25ml of absolute ethanol and heat to above 50 degrees for about three hours, wait for the complete evaporation of absolute ethanol (can be judged by comparing with the original oil phase liquid level) Volatility), since the present embodiment prepares saturated saponified kerosene, the added solid sodium hydroxide is excessive, so the saponified product is filtered through 100 mesh filter paper to remove excess solid sodium hydroxide, and saturated saponified kerosene is obtained;

[0048] c. Take 1.2ml of saponified Cyanex272 and 8.8ml of satura...

Embodiment 2

[0054] a. Add 0.2g of solid sodium hydroxide to 10ml of Cyanex272, stir with a magnet, add 5ml of absolute ethanol and heat to above 50°C for about three hours, wait for the complete evaporation of absolute ethanol (can be determined by comparing with the original oil phase liquid level) Judging volatilization), saponified Cyanex272 was obtained;

[0055] b. Add 2g of solid sodium hydroxide to 50ml of kerosene, stir with a magnet, add 25ml of absolute ethanol and heat to above 50 degrees for about three hours, wait for the complete evaporation of absolute ethanol (can be judged by comparing with the original oil phase liquid level) Volatility), since the present embodiment prepares saturated saponified kerosene, the added solid sodium hydroxide is excessive, so the saponified product is filtered through 100 mesh filter paper to remove excess solid sodium hydroxide, and saturated saponified kerosene is obtained;

[0056] c. Take 1.2ml of saponified Cyanex272 and 8.8ml of satura...

Embodiment 3

[0064] The difference between this embodiment and embodiment 2 is only that the kerosene used to prepare the organic solvent is changed to sulfonated kerosene, and the others are the same as in embodiment 2.

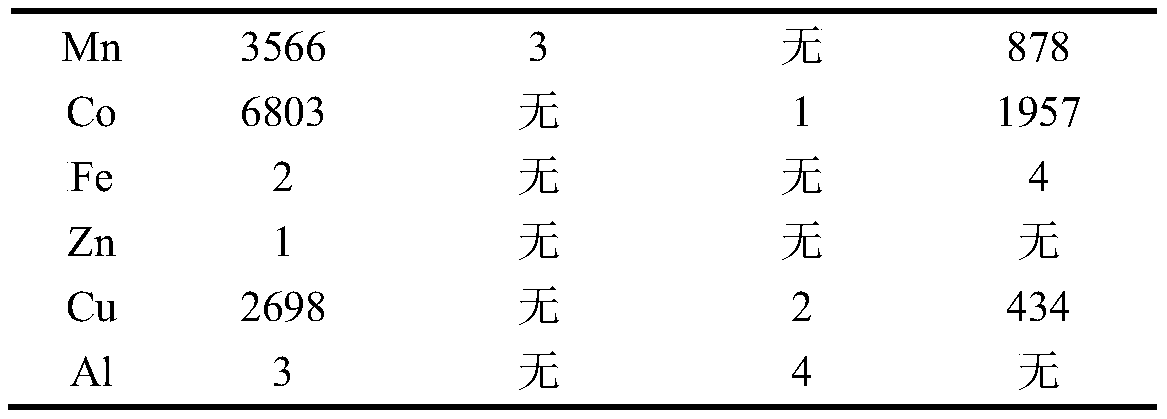

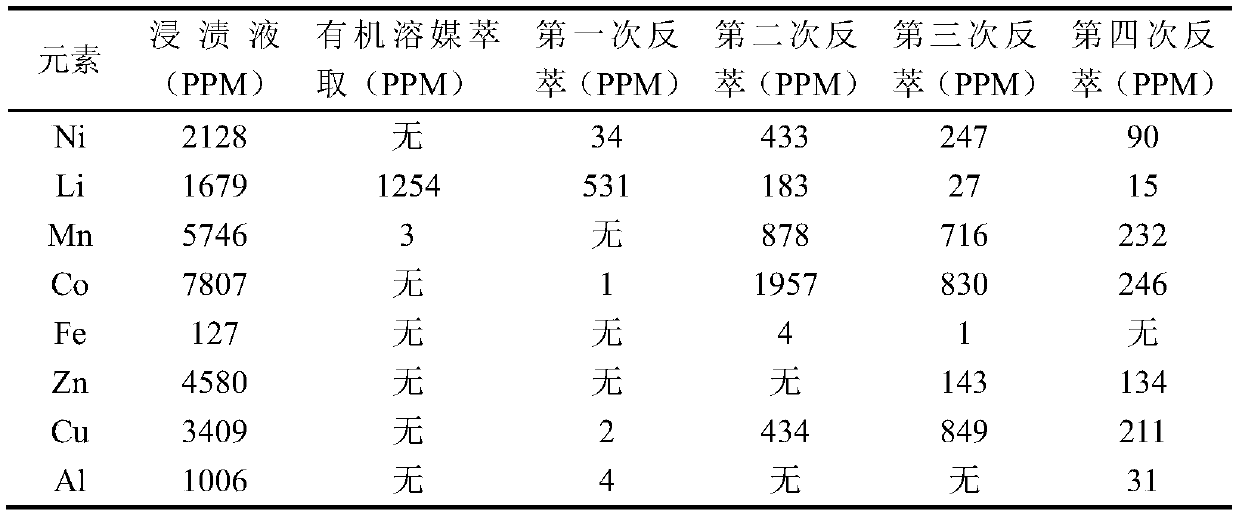

[0065] Similarly, carry out ICP (inductively coupled plasma spectrometer / inductively coupled plasma emission spectrometer) detection to the aqueous phase of step f, the aqueous phase of g back-extraction gained, the water phase of h each back-extraction gained, determine wherein each element content , and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com