Preparation method for composite conductive film doped with tin oxide

A composite conductive and tin oxide technology, which is used in the manufacture of conductive/semiconductive layer equipment, cable/conductor manufacturing, circuits, etc., can solve the problems of poor conductivity of tin oxide films, etc., and achieve good conductive effect and firm adsorption , the effect of increasing the carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of doped tin oxide composite conductive film, comprising the steps of:

[0027] (1) SnCl 4 1. The dopant is dissolved in an organic solvent to obtain a mixed solution; the dopant is yttrium nitrate-antimony trichloride, the molar ratio of the two is 0.4:1, and the dopant and SnCl 4 The molar ratio is 1:50, SnCl 4 The concentration is 0.5mol / L, and the organic solvent is a mixture of ethanol and dimethylformamide with a volume ratio of 1:1;

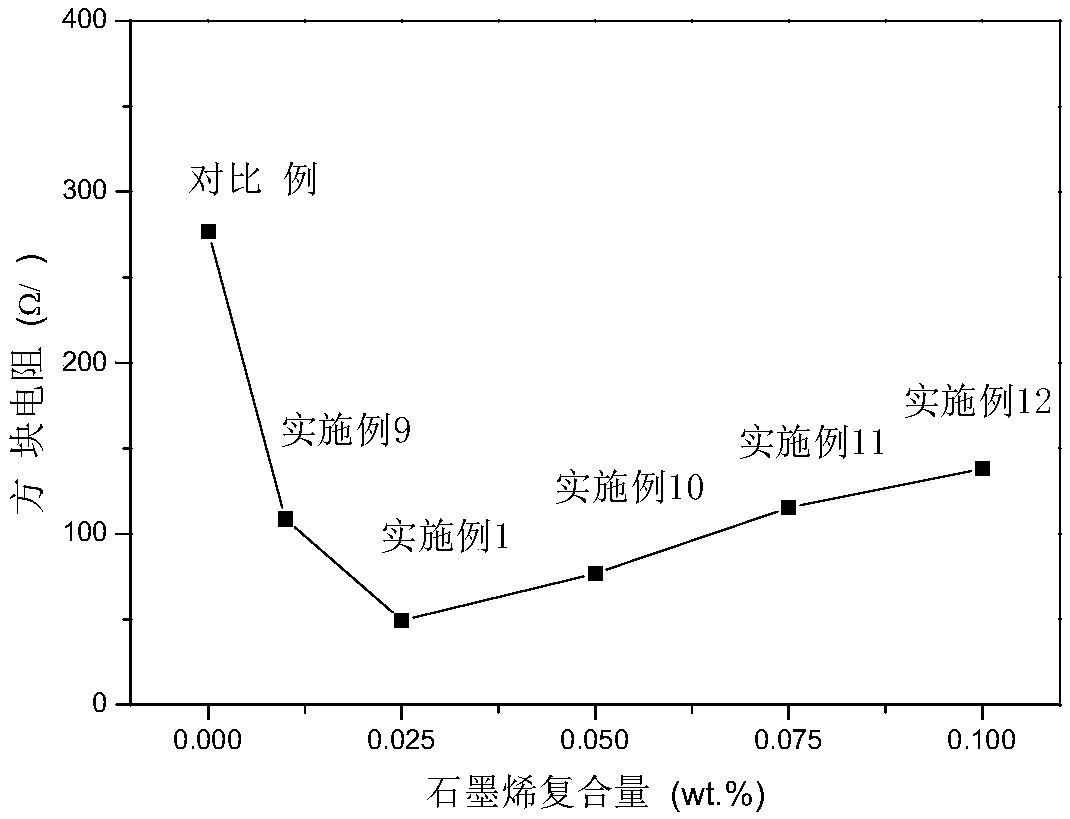

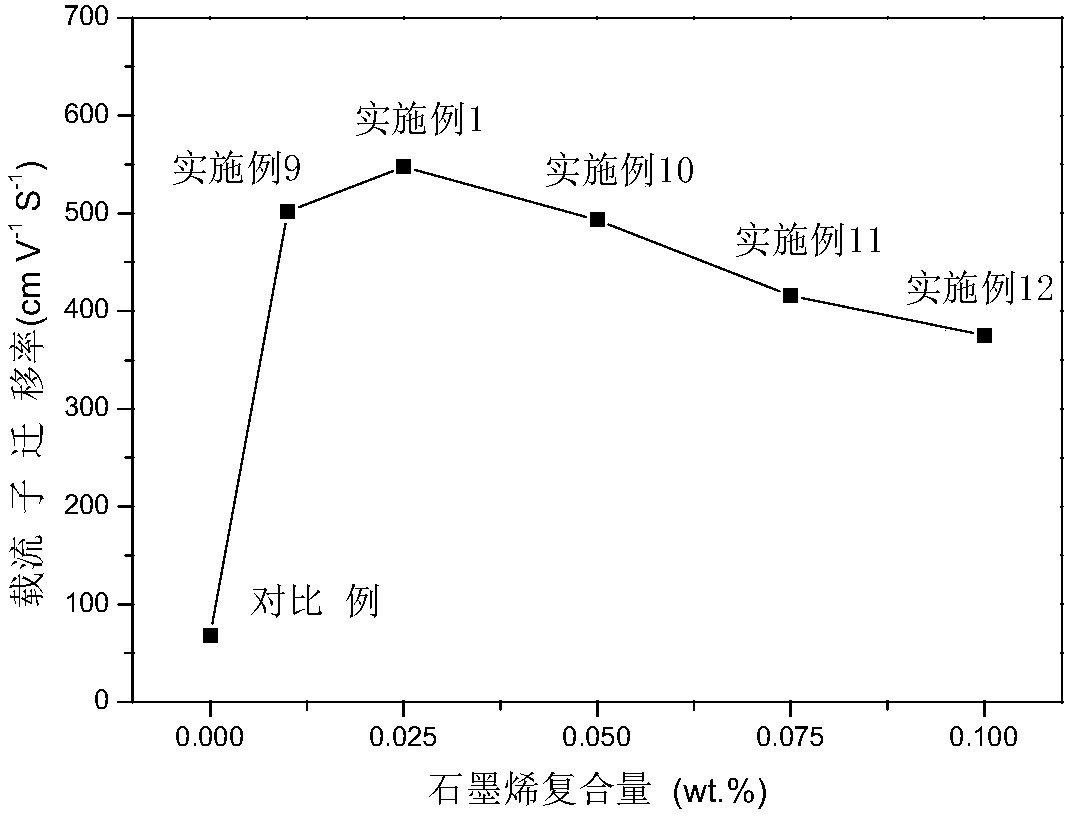

[0028] (2) After the mixed solution of step (1) is left to stand for 12h, add graphene, graphene and SnCl 4 The mass ratio of the mixture is 0.025:100, the ultrasonic dispersion is uniform, and the mixed solution containing graphene is obtained;

[0029] (3) Step (1) is repeated to prepare a graphene-free mixed solution, and the graphene-containing mixed solution obtained in step (2) is passed through an ultrasonic spray pyrolysis coating machine (substrate temperature is 390 ° C, liquid injection Speed: 20m...

Embodiment 2

[0031] The dopant is yttrium nitrate-antimony trichloride, the molar ratio of the two is 0.8:1, and the rest are the same as in Example 1.

Embodiment 3

[0033] Dopant and SnCl in the step (1) 4 Molar ratio is 1:25, and all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com