Flexible asymmetric supercapacitor with super high energy density and preparation method thereof

A supercapacitor, energy density technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve environmental pollution, toxicity and other problems, achieve broad application prospects, long cycle life, excellent soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

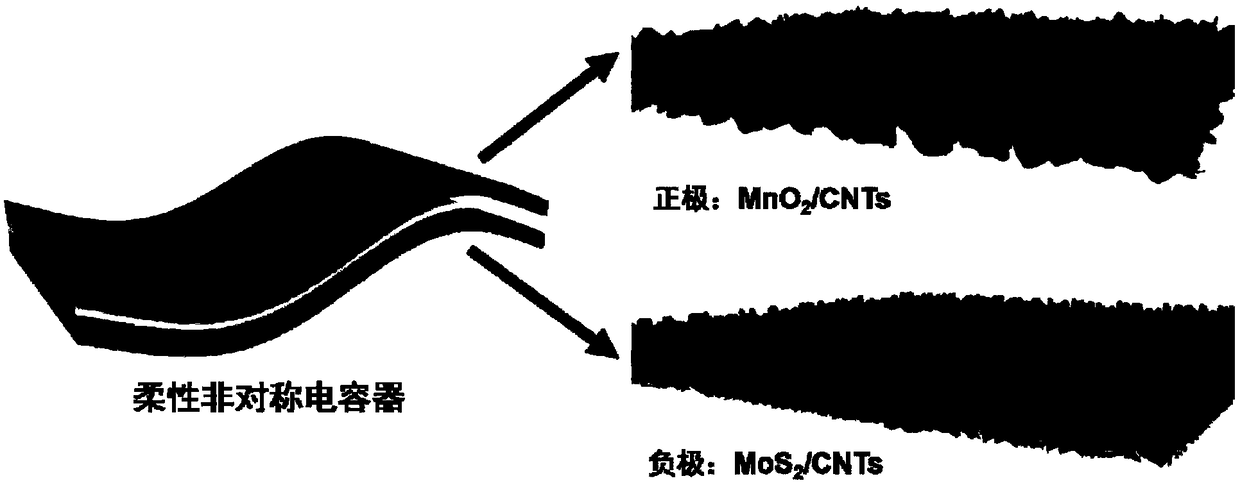

[0058] A flexible asymmetric supercapacitor with ultrahigh energy density, the structure of the supercapacitor is as follows figure 1 As shown, it includes the electrode plates on both sides and the electrolyte layer in the middle of the two electrode plates. The positive electrode plate is a carbon nanotube film with manganese dioxide nanosheets grown on both sides, and the negative electrode plate is a carbon nanotube film grown on both sides. The carbon nanotube film of the molybdenum sulfide nanosheet, the electrolyte in the electrolyte layer is a lithium chloride system of polyvinyl alcohol.

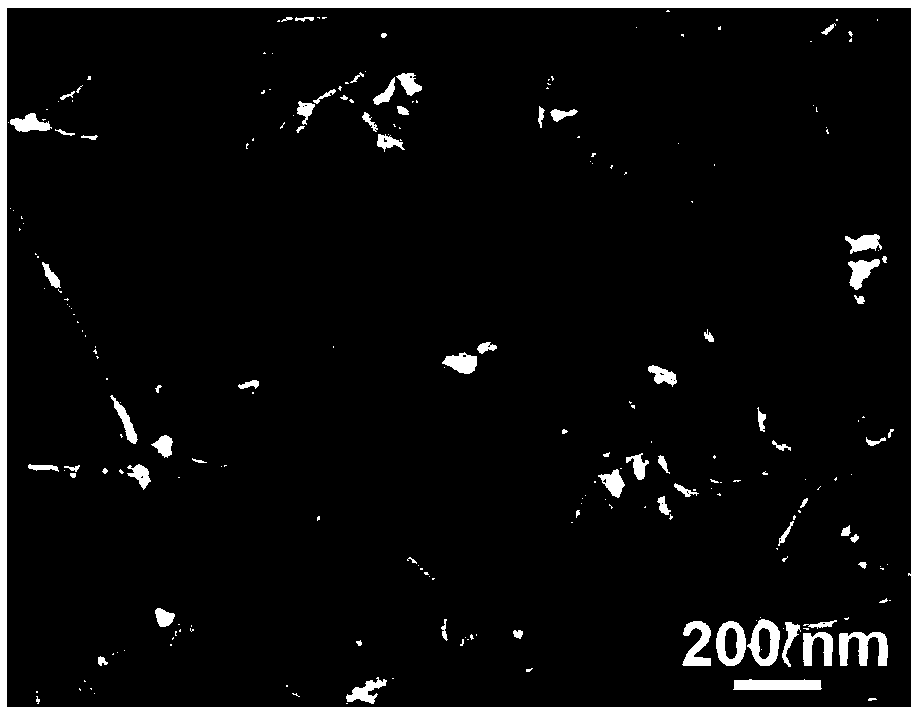

[0059] Carbon nanotube / manganese dioxide composites were prepared by electrochemical deposition in a three-electrode system: the nitric acid-treated carbon nanotube film, platinum sheet, and silver / silver chloride electrode were used as the working electrode, counter electrode, and reference electrode, respectively. Electrode, electrolyte contains 0.05mol L -1 Manganese sulfate, 0....

Embodiment 2

[0067] Adopt and embodiment 1 similar preparation method, specifically as follows:

[0068] (1) With the carbon nanotube thin film soaked in nitric acid as the working electrode, the platinum sheet as the counter electrode, and the silver / silver chloride electrode as the reference electrode, use 0.05mol L -1 Manganese sulfate, 0.05mol L -1 The mixed aqueous solution of sodium acetate and 15% volume ethanol was used as the electrolyte for electrochemical deposition, and the electrochemical deposition was performed at 4mA cm -2 It was carried out at a constant current density for 40 minutes. After the electrochemical deposition was completed, it was rinsed with deionized water for 3 to 5 times, and then dried at 55°C for 2 hours to obtain a positive electrode plate.

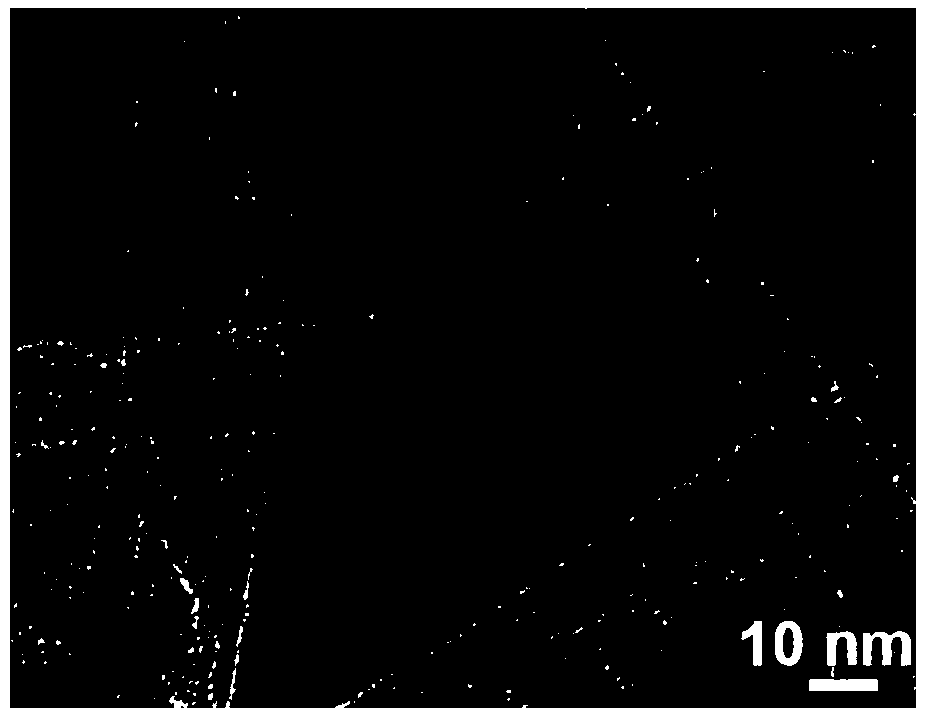

[0069] (2) Dissolve 0.519g ammonium molybdate tetrahydrate and 3.1955g thiourea in deionized water to obtain a mixed solution, then soak the treated carbon nanotube film in nitric acid into the mixed solution, and...

Embodiment 3

[0074] Adopt and embodiment 1 similar preparation method, specifically as follows:

[0075] (1) With the carbon nanotube film soaked in nitric acid as the working electrode, the platinum sheet as the counter electrode, and the silver / silver chloride electrode as the reference electrode, use 0.1mol L -1 Manganese sulfate, 0.1mol L -1 The mixed aqueous solution of sodium acetate and 10% volume ethanol was used as the electrolyte for electrochemical deposition, and the electrochemical deposition was performed at 5mA cm -2 It was carried out at a constant current density for 10 minutes. After the electrochemical deposition was completed, it was rinsed with deionized water for 3 to 5 times, and then dried at 65°C for 1 hour to obtain the positive electrode plate.

[0076] (2) Dissolve 3.638g ammonium molybdate tetrahydrate and 0.4565g thiourea in deionized water to obtain a mixed solution, then immerse the carbon nanotube film treated by soaking nitric acid in the mixed solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com