Method for catalyzing oxidation of methacrolein to methacrylic acid

A technology of methacrolein and methacrylic acid, used in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

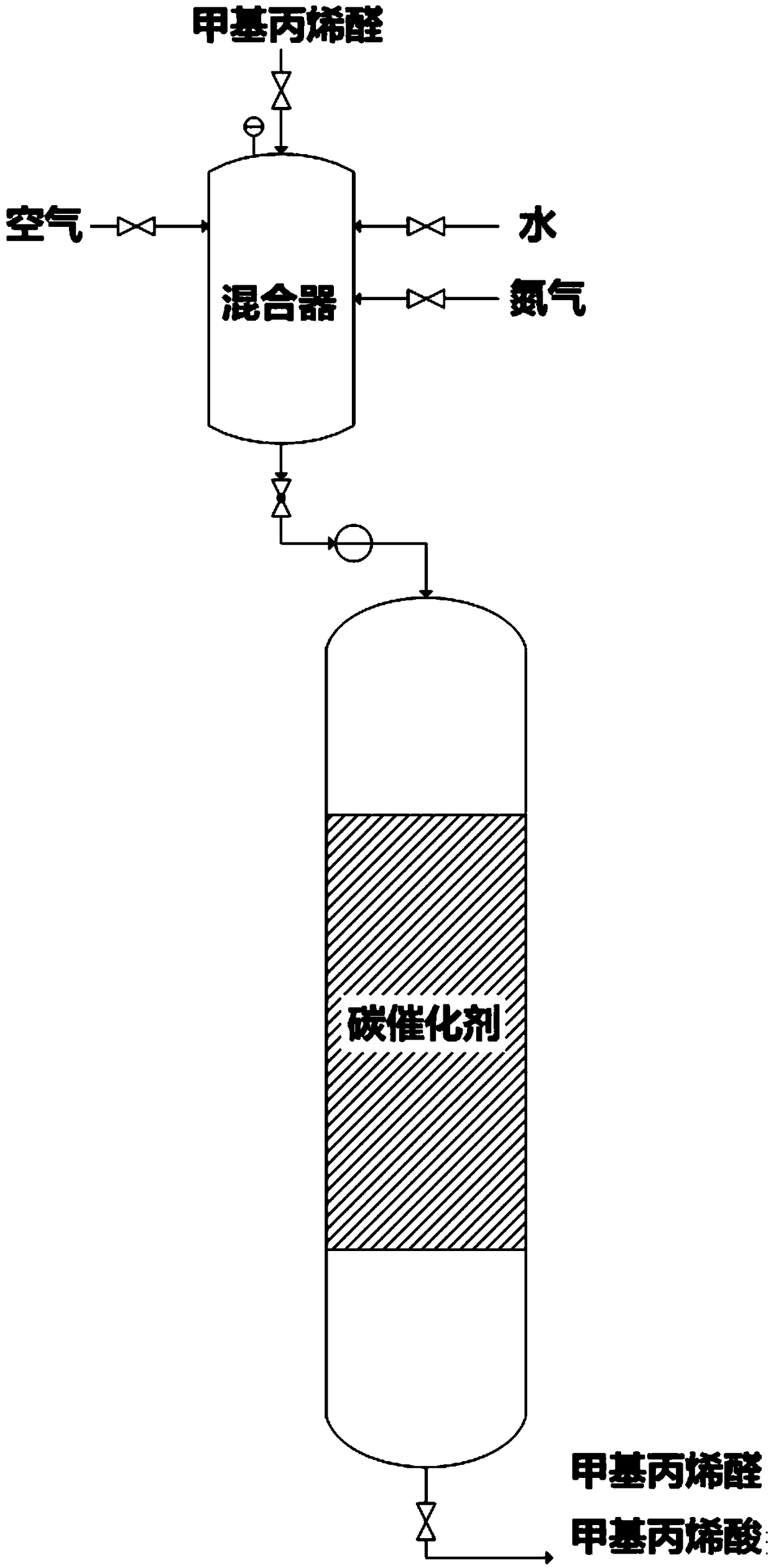

Method used

Image

Examples

Embodiment 1

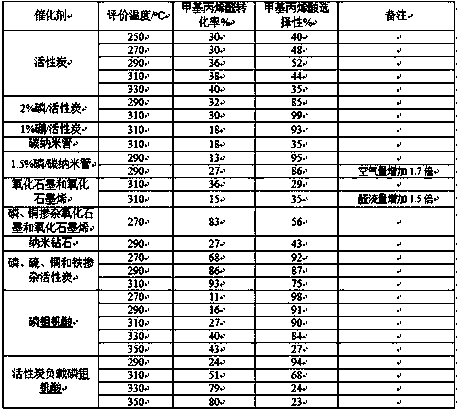

[0022] After washing with water, 100 ml of cylindrical activated carbon with a diameter of 2 mm and a height of 4 mm was charged into a fixed bed reactor with a diameter of 25 mm and a length of 2000 mm. The other space in the reactor is filled with inert alumina ceramic balls. The feed rate of methacrolein is 0.2 mol / h, the air feed rate is 60 L / h, the water feed rate is 0.15 mol / h, and the nitrogen feed rate is 36 L / h. The reaction pressure is 1 atmosphere. The reaction temperature was set to 250 oC , 270 oC , 290 oC , 310 oC And 330 oC . After 6 hours of reaction, sampling and analysis were started. Liquid samples were detected by gas chromatography FID detector, and gas samples were detected by gas chromatography TCD detector. 250 o At C, the conversion rate of methacrolein is 30%, and the selectivity of methacrylic acid is 40%; 270 o At C, the conversion rate of methacrolein is 30%, and the selectivity of methacrylic acid is 48%; 290 o At C, the conversion rate of methac...

Embodiment 2

[0024] Take 200g of activated carbon and take 14.8g of 85% phosphoric acid to make a solution of 1.2 times the volume of activated carbon. Put the activated carbon into the prepared phosphoric acid solution and stir vigorously at room temperature for 2 hours. After the phosphoric acid solution is completely absorbed by the activated carbon, 100 o C dry for 24 hours. Put the dried activated carbon at 350 oC Calcined for 12 hours, a carbon catalyst with a phosphorus loading of 2% was prepared.

[0025] The catalyst evaluation reactor, the filling amount and the reactant feed rate are as in Example 1. The filling catalyst is activated carbon doped with 2% phosphorus, and the evaluation temperature is 290 o C and 310 o C. 290 o At C, the conversion rate of methacrolein is 32%, and the selectivity of methacrylic acid is 85%; 310 o At C, the conversion of methacrolein is 30%, and the selectivity of methacrylic acid is 99%. At 310 oC After 200 hours of continuous operation, the conversi...

Embodiment 3

[0027] Take 200g of activated carbon, take 11g of boric acid to make a solution 1.5 times the volume of activated carbon, put the activated carbon into the prepared boric acid solution, stir vigorously at room temperature for 2 hours, wait until the phosphoric acid aqueous solution is completely absorbed by the activated carbon, 100 o C dry for 24 hours. Put the dried activated carbon at 350 oC After calcining for 12 hours, a carbon catalyst with a boron loading of 1% was prepared.

[0028] The catalyst evaluation reactor, the filling amount and the reactant feed rate are as in Example 1. The filling catalyst is activated carbon doped with 1% boron, and the evaluation temperature is 310 o C. The conversion rate of methacrolein was 18%, and the selectivity of methacrylic acid was 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com