Preparation method for ipratropium bromide

A technology of ipratropium bromide and ipratropium bromide is applied in the field of preparation of ipratropium bromide, can solve the problems of high equipment sealing requirements, inconvenient use, storage and transportation, volatile, etc. requirements, enhance safety, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

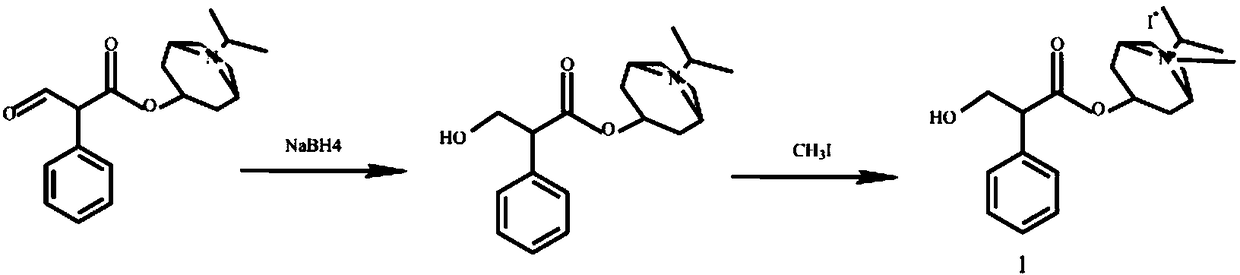

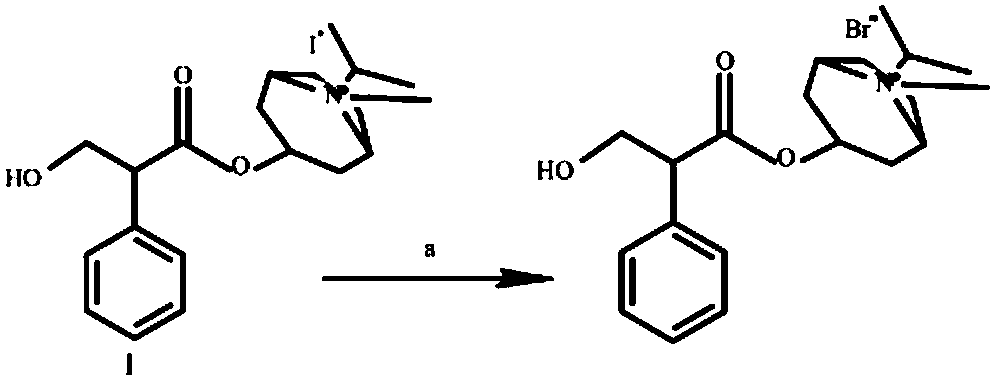

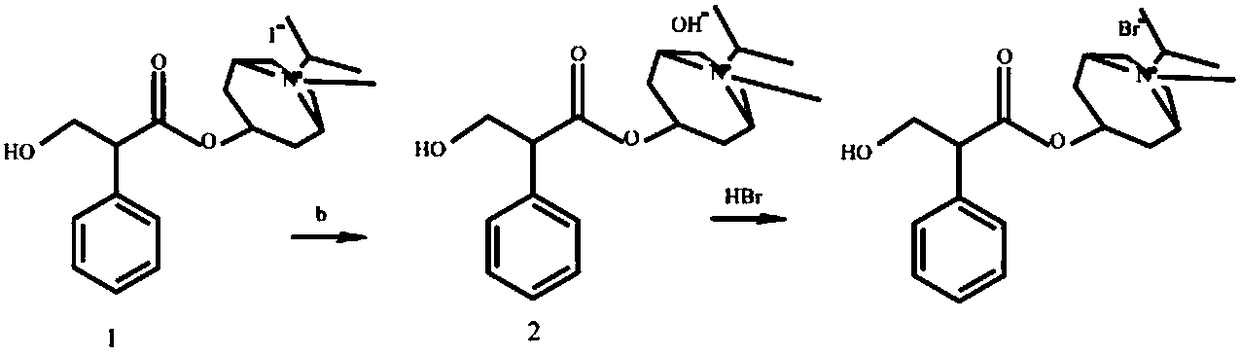

Method used

Image

Examples

Embodiment 1

[0041] Preparation of Isopropyltropine

[0042] 10g of α-formylphenylacetic acid-N-isopropyltropine ester was dissolved in 60ml of chloroform and 20ml of water. Add 1.24 g of sodium borohydride, react at room temperature for 5 hours, separate the layers, extract the aqueous layer twice with 20 ml of chloroform, and combine the organic layers. After drying, the solvent was concentrated and recrystallized with ethyl acetate:petroleum ether=1:3 to obtain 8.2g of isopropyltropine.

[0043] Methylation of Isopropyltropine

[0044] Add 3 g of isopropyltropine into 12 ml of acetone, stir for 30 minutes to dissolve, and cool down to 0-5°C in an ice bath. Add 1.8g of methyl iodide, keep the temperature at 15-20°C, stir the reaction for 5 hours, evaporate the solvent to dryness under reduced pressure at 40°C, and recrystallize with ethyl acetate:methanol=3:1 to obtain 3.9g of the product with a yield of 93%.

[0045] The preparation of ipratropium bromide

[0046] 2 g of ipratropium...

Embodiment 2

[0048] Preparation of Isopropyltropine

[0049]10g of α-formylphenylacetic acid-N-isopropyltropine ester was dissolved in 60ml of chloroform and 20ml of water. Add 1.24 g of sodium borohydride, react at room temperature for 5 hours, separate the layers, extract the aqueous layer twice with 20 ml of chloroform, and combine the organic layers. After drying, the solvent was concentrated and recrystallized with ethyl acetate:petroleum ether=1:3 to obtain 8.2g of isopropyltropine.

[0050] Methylation of Isopropyltropine

[0051] Add 3 g of ipropyltropine into 6 ml of methanol and 6 ml of water, stir for 30 minutes to dissolve, and cool down to 0-5°C in an ice bath. Add 1.8g of methyl iodide, keep the temperature at 15-20°C, stir the reaction for 5 hours, evaporate the solvent to dryness under reduced pressure at 40°C, and recrystallize with ethyl acetate:methanol=3:1 to obtain 4.2g of the product with a yield of 96%.

[0052] The preparation of ipratropium bromide

[0053] Dis...

Embodiment 3

[0055] Preparation of Isopropyltropine

[0056] 10g of α-formylphenylacetic acid-N-isopropyltropine ester was dissolved in 60ml of chloroform and 20ml of water. Add 1.24 g of sodium borohydride, react at room temperature for 5 hours, separate the layers, extract the aqueous layer twice with 20 ml of chloroform, and combine the organic layers. After drying, the solvent was concentrated and recrystallized with ethyl acetate:petroleum ether=1:3 to obtain 8.2g of isopropyltropine.

[0057] Methylation of Isopropyltropine

[0058] Add 3 g of isopropyltropine into 6 ml of acetone and 6 ml of water, stir for 30 minutes to dissolve, and cool down to 0-5°C in an ice bath. Add 1.8g of methyl iodide, keep the temperature at 15-20°C, stir the reaction for 5 hours, evaporate the solvent to dryness under reduced pressure at 40°C, and recrystallize with ethyl acetate:methanol=3:1 to obtain 3.8g of the product with a yield of 92%.

[0059] The preparation of ipratropium bromide

[0060] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com