Aircraft fuel tank sealant and preparation method thereof

A technology for aircraft fuel tanks and sealants, applied in the field of sealants, can solve problems such as poor adhesion, reduced adhesion of sealants to substrates, debonding failure of aircraft fuel tank sealants, etc., to achieve broad market application prospects and reduce swelling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of fluorine-modified hollow glass microspheres:

[0029] (1) Pickling: Mix 30wt% hydrogen peroxide and concentrated sulfuric acid at a volume ratio of 7:3, add hollow glass microspheres to the mixed solution, filter and dry after ultrasonic cleaning for 30 minutes;

[0030] (2) Alkali washing: Mix 30%wt hydrogen peroxide, 25%wt ammonia water and water at a volume ratio of 1:1:5, add hollow glass microspheres to the mixed solution, ultrasonicate at 55±5°C for 60min, filter and dry ;

[0031] (3) Surface modification: Dissolve perfluoropolyether trimethoxysilane in 1%wt ethanol solution, adjust the pH value to 3.0, add 5g of hollow glass microspheres pretreated by acid washing and alkali washing, 50 °C ultrasonically stirred for 2 hours, filtered and dried to obtain fluorine-modified hollow glass microspheres.

Embodiment 2

[0033] Preparation of aircraft fuel tank sealant:

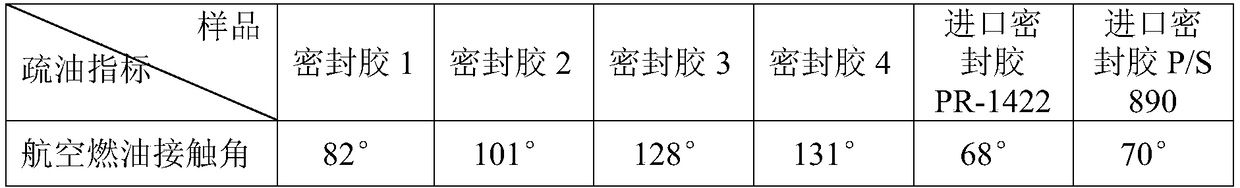

[0034] Get 100g of liquid polysulfide raw rubber, 0.5g of fluorine-modified hollow glass microspheres, 40g of calcium carbonate, 5g of fumed silica, 1g of octadecanoate, 20g of butyl benzyl phthalate and 5g of epoxy resin in Grind on the three-roll mill for 10 minutes as the base paste; take 100g of manganese dioxide, 20g of butyl benzyl phthalate, 5g of 1,3-biphenylguanidine and 10g of carbon black, and grind on the three-roll mill for 10 minutes As a vulcanized paste, a two-component sealant is obtained, and the two components are mixed and stirred evenly to obtain the sealant 1 during use.

Embodiment 3

[0036] Preparation of aircraft fuel tank sealant:

[0037] Take 100g of liquid polysulfide raw rubber, 1g of fluorine-modified hollow glass microspheres, 20g of calcium carbonate, 10g of fumed silica, 2g of octadecanoate, 15g of butyl benzyl phthalate and 8g of epoxy resin in three Grind on the roller mill for 5 minutes as base paste; get 100g of manganese dioxide, 10g of butyl benzyl phthalate, 10g of 1,3-biphenylguanidine and 15g of carbon black, grind for 5 minutes on the three-roll mill as vulcanization paste to obtain a two-component sealant, and to obtain the sealant 2 after mixing the two components evenly during use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com