High-temperature proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and high temperature, applied in the direction of fuel cells, electrochemical generators, electrical components, etc. The adsorption capacity of the basement membrane is not strong, etc., to achieve the effect of low raw material prices, low requirements for equipment and reaction conditions, and high-temperature proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

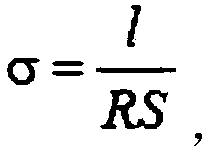

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a high-temperature proton exchange membrane, comprising the steps of:

[0031] 1) Preparation of bishydroxyethyl sulfone-4,5-dicarboxyimidazole polycondensate: dissolve 10 g of bishydroxyethyl sulfone, 10 g of 4,5-dicarboxyimidazole, and 3 g of zirconium sulfate in 50 g of toluene, and add In a round-bottomed flask with a water separator, stir the reaction at 80°C for 2 hours under a nitrogen atmosphere, and 6 hours at a temperature of 110°C, then remove the solvent by rotary evaporation, and wash the product with water for 3 times, then wash with ethyl acetate Wash 4 times, and finally place it in a vacuum drying oven at 80°C for 10 hours;

[0032] 2) Modification of the polycondensate: dissolve 12 g of the polycondensate prepared in step 1), 4 g of 2-chloroethyl methanesulfonic acid, and 4 g of sodium cyanide in 40 g of dimethyl sulfoxide, and stir the reaction at 70° C. 4 hours, then settle out in water, wash 5 times with water, and dry in a v...

Embodiment 2

[0038] A method for preparing a high-temperature proton exchange membrane, comprising the steps of:

[0039] 1) Preparation of bishydroxyethyl sulfone-4,5-dicarboxyimidazole polycondensate: dissolve 10 g of bishydroxyethyl sulfone, 10 g of 4,5-dicarboxyimidazole, and 4 g of cerium sulfate in 60 g of toluene, and add In a round-bottomed flask with a water separator, stir the reaction at 83°C for 2.2 hours under a helium atmosphere, and stir the reaction at a temperature of 115°C for 6.5 hours. After that, the solvent is removed by rotary evaporation, and the product is washed with water for 4 times, and then washed with ethyl acetate The ester was washed 5 times, and finally placed in a vacuum oven at 83°C for 11 hours;

[0040] 2) Modification of polycondensate: dissolve 14 g of polycondensate prepared in step 1), 4 g of 2-chloroethyl methylsulfonic acid, and 5 g of potassium tert-butyl alkoxide in 45 g of N,N-dimethylformamide , stirred and reacted at 72°C for 4.5 hours, the...

Embodiment 3

[0046] A method for preparing a high-temperature proton exchange membrane, comprising the steps of:

[0047] 1) Preparation of bishydroxyethyl sulfone-4,5-dicarboxyimidazole polycondensate: 10 g of bishydroxyethyl sulfone, 10 g of 4,5-dicarboxyimidazole, and 5 g of tetrabutyl titanate were dissolved in 75 g of toluene, and Add it into a round-bottomed flask with a water separator, stir and react at 85°C for 2.5 hours under a neon gas atmosphere, and stir for 7 hours at a temperature of 120°C, then remove the solvent by rotary evaporation, and wash the product with water 4 times, and then Washed 6 times with ethyl acetate, and finally placed in a vacuum oven at 85°C for 12 hours;

[0048] 2) Modification of the polycondensate: dissolve 16 g of the polycondensate prepared in step 1), 4 g of 2-chloroethyl methylsulfonic acid, and 6 g of potassium hydroxide in 50 g of N-methylpyrrolidone, and stir at 75° C. Reacted for 5 hours, then precipitated in water, washed 6 times with wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com