Double-stimulation expanding gel particle for preventing gas channeling in process of carbon dioxide oil displacement and preparation method of double-stimulation expanding gel particle

A technology for carbon dioxide and oil displacement process, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor solubility, insufficient tolerance, high industrial cost, and achieve the effect of simple composition and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]

[0035] Dissolve 56.80g of AM monomer in 180.00g of pure water, add 0.04g of cross-linking agent MBA, 3.60g of SBMA, and 2.08g of DMAEMA to the solution in sequence, and stir until it becomes clear to obtain a mixed monomer solution polymerization system. Nitrogen was passed through the system to remove oxygen for 30 minutes; 0.12g of potassium persulfate was weighed and dissolved in 6.00g of water to prepare an initiator solution; the mixed monomer solution and the initiator solution were mixed, and the mixed reaction solution was reacted in a water bath at 40°C After 10.0 hours, continue to heat up to 60°C for 8.0 hours to increase the conversion rate. After the reaction is completed, a copolymerized gel is obtained, and the dried product is pulverized with a 12000r / min universal pulverizer. The crushing operation is as follows: after crushing for 2 seconds, stand still for 8 seconds, repeat this cycle operation ten times, and use fans to dissipate heat. The obta...

Embodiment 2

[0037]

[0038] Dissolve 56.80g of AM monomer in 180.00g of pure water, add 0.04g of cross-linking agent MBA, 3.60g of SBMA, and 4.16g of DMAEMA to the solution in sequence, and stir until it becomes clear to obtain a mixed monomer solution polymerization system. Nitrogen was passed through the system to remove oxygen for 30 minutes; 0.12g of potassium persulfate was weighed and dissolved in 6.00g of water to prepare an initiator solution; the mixed monomer solution and the initiator solution were mixed, and the mixed reaction solution was reacted in a water bath at 40°C After 10.0 hours, continue to heat up to 60°C for 8.0 hours to increase the conversion rate. After the reaction is completed, a copolymerized gel is obtained, and the dried product is pulverized with a 12000r / min universal pulverizer. The crushing operation is as follows: after crushing for 2 seconds, stand still for 8 seconds, repeat this cycle operation ten times, and use fans to dissipate heat. The obta...

Embodiment 3

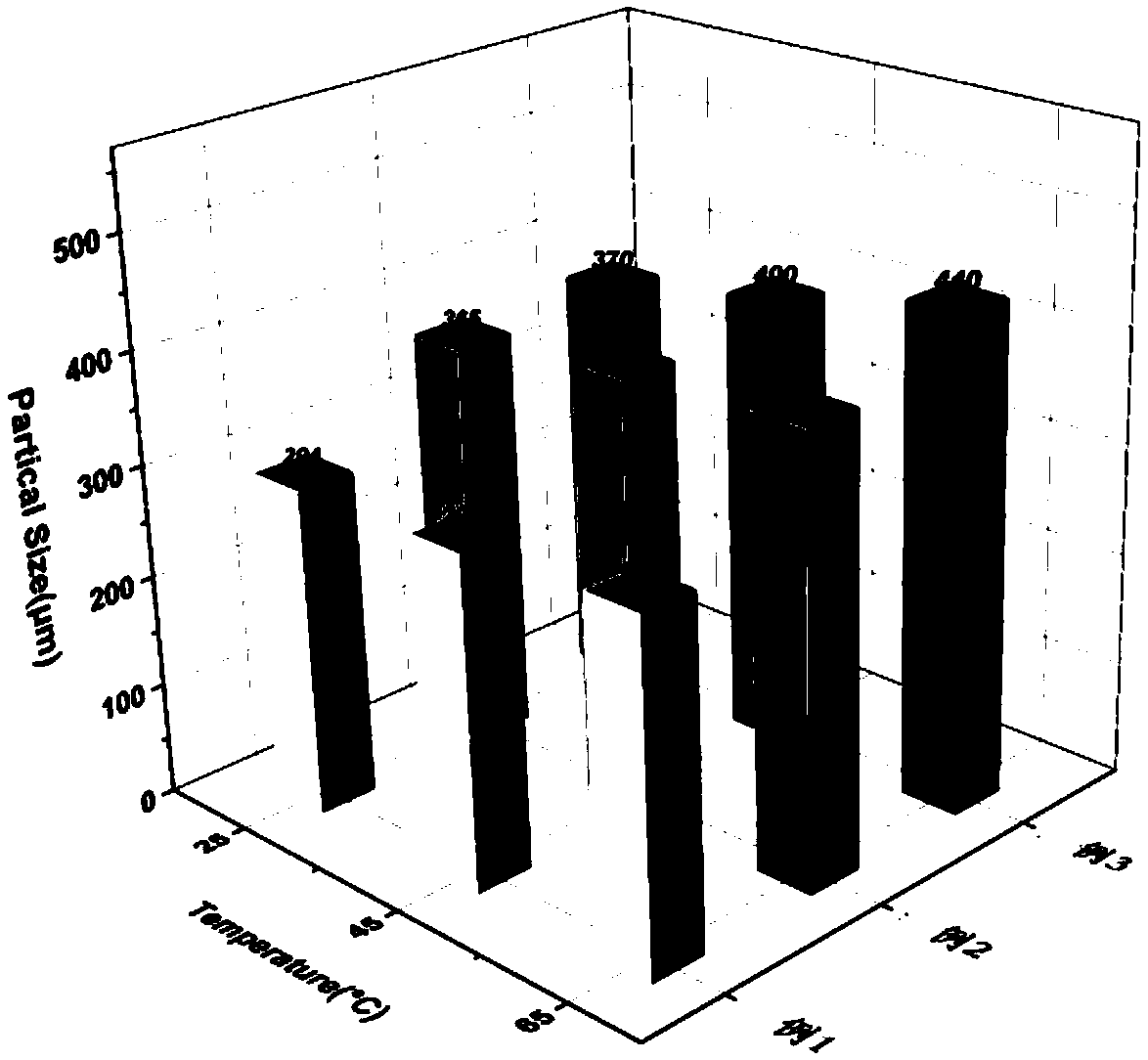

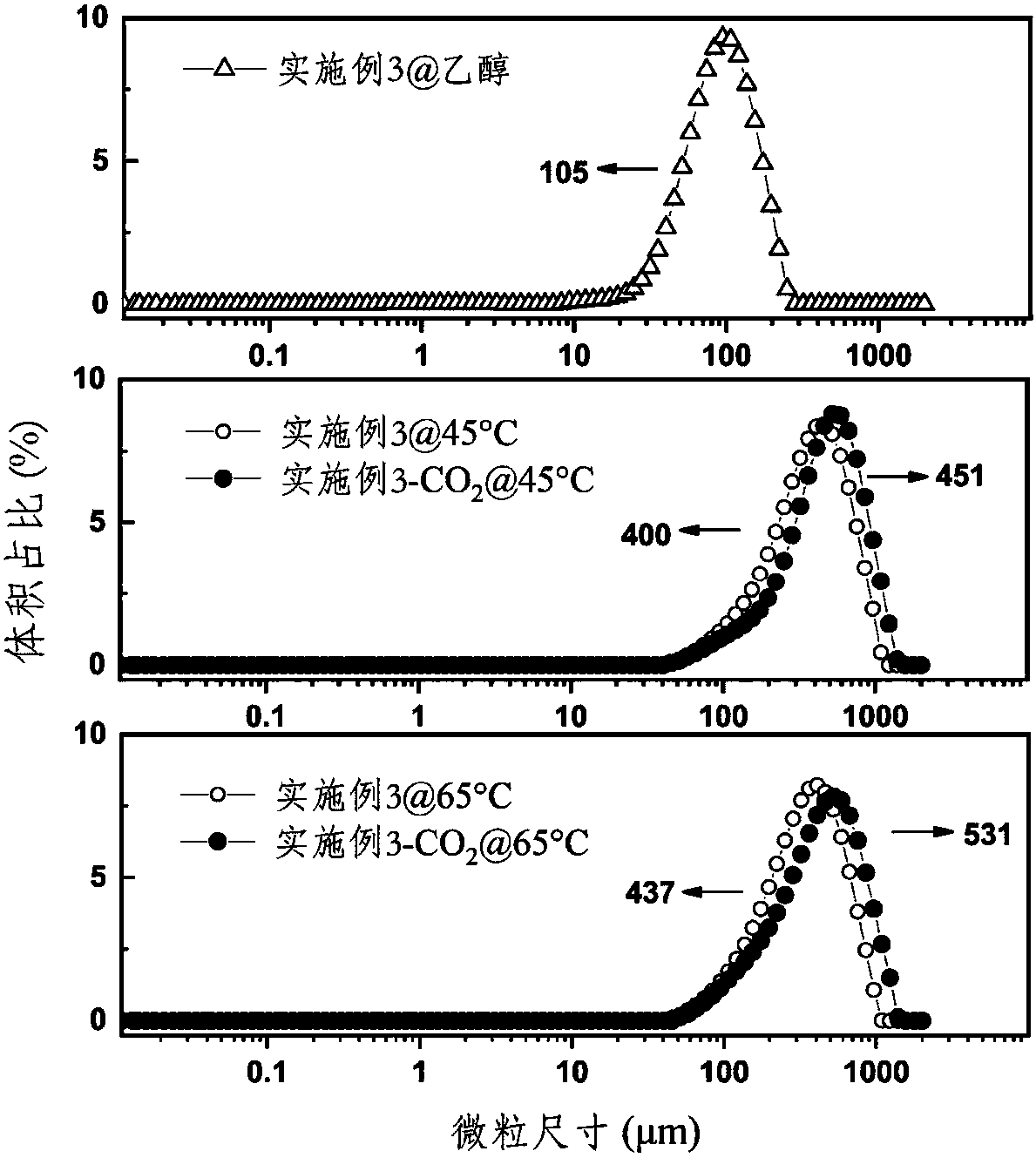

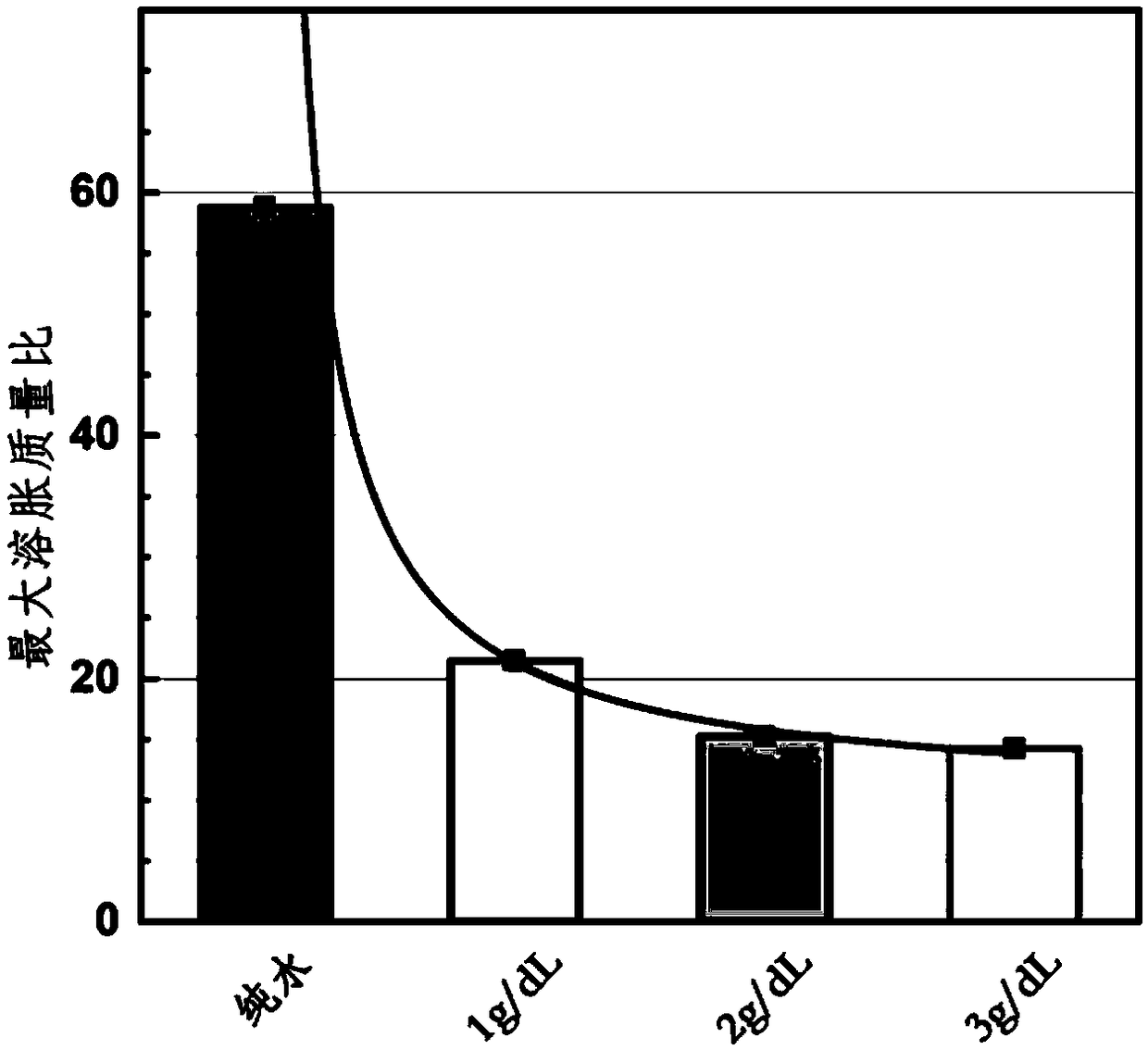

[0040]

[0041]

[0042] Dissolve 56.80g of AM monomer in 180.00g of pure water, add 0.02g of cross-linking agent MBA, 3.60g of SBMA, 4.16g of DMAEMA to the solution in turn, stir until clarified to obtain a mixed monomer solution polymerization system, and add to the polymerization system while stirring evenly Nitrogen was passed through the system to remove oxygen for 30 minutes; 0.12g of potassium persulfate was weighed and dissolved in 6.00g of water to prepare an initiator solution; the mixed monomer solution and the initiator solution were mixed, and the mixed reaction solution was reacted in a water bath at 40°C After 10.0 hours, continue to heat up to 60°C for 8.0 hours to increase the conversion rate. After the reaction is completed, a copolymerized gel is obtained, and the dried product is pulverized with a 12000r / min universal pulverizer. The crushing operation is as follows: after crushing for 2 seconds, stand still for 8 seconds, repeat this cycle operation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com