A kind of powder coating for spraying on the surface of thermos cup

A technology of powder coating and surface spraying, which is applied in the direction of powder coating, polyester coating, anti-fouling/underwater coating, etc., and can solve the problem of poor water boiling resistance, abrasion resistance, poor weather resistance, surface powder coating coating, etc. Poor adhesion and other problems, to achieve the effect of improving scratch resistance and salt spray corrosion resistance, improving scratch resistance and hand feeling, and reducing paint piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

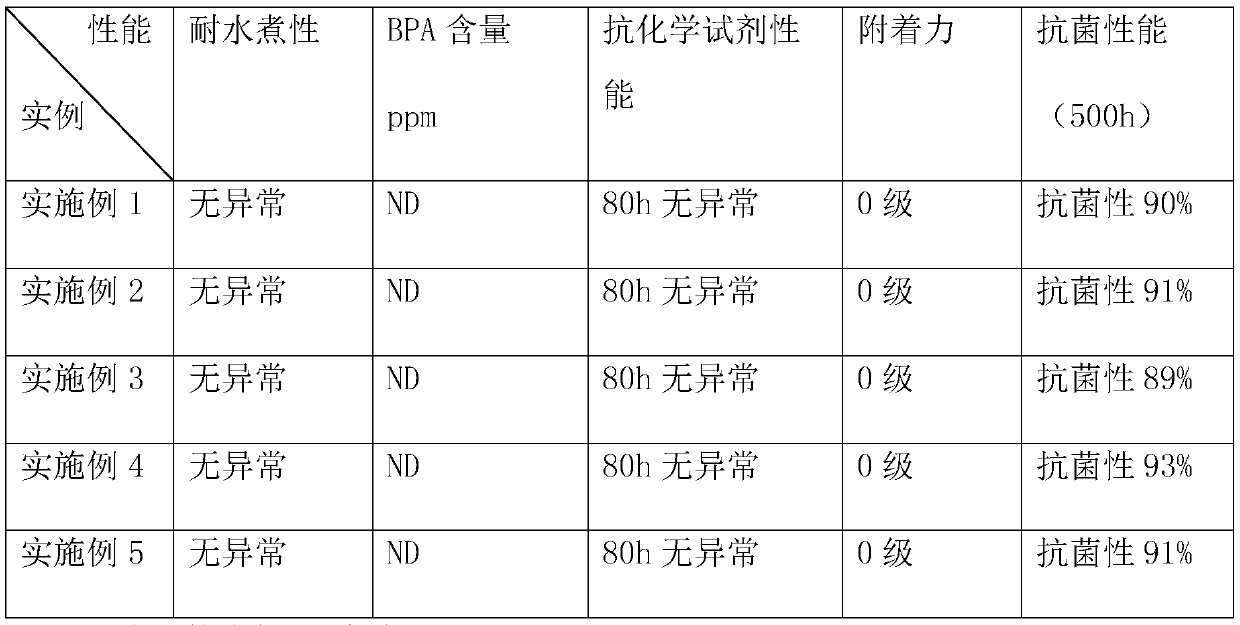

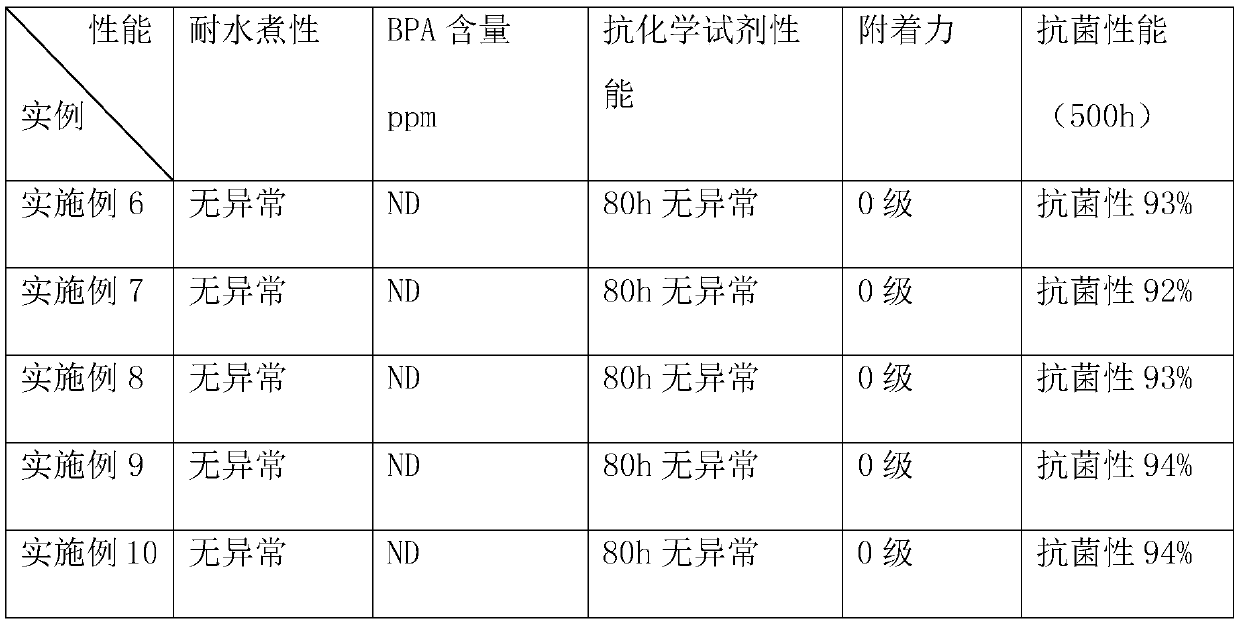

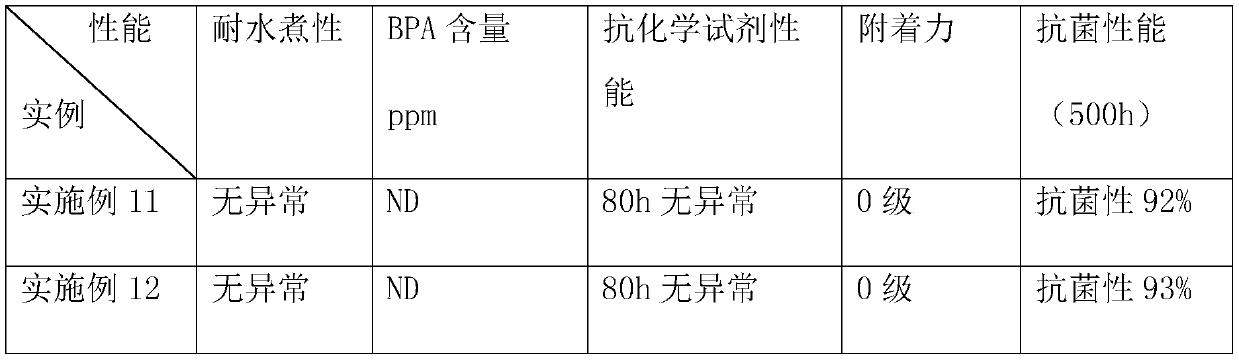

Examples

Embodiment 1

[0059] Embodiment 1 A kind of plane powder coating that is used for thermos cup surface spraying

[0060] Formula: GH-2208 50%, XL552 2.8%, NW-5 2%, Silica Powder 40.5%, GLP588 0.7%, Carbon Black 1%, 701B 0.6%, HY-KYZ01 1.5%, Benzoin 0.4%, PTFE Wax powder 0.5%.

[0061] Preparation method: the specific steps are:

[0062] (1) Take carboxyl-terminated polyester resin, XL552, NW-5, microsilica powder B, GLP588, carbon black, 701B, HY-KYZ01, benzoin and polytetrafluoroethylene wax according to the parts by weight and ratio described in the present invention powder, placed in a high-speed mixer and mixed for 5 minutes to obtain a mixture;

[0063] (2) extruding the mixture obtained in step (1) in a twin-screw melting extruder at a temperature of 100° C. to obtain an extrudate;

[0064] (3) The extruded material obtained in step (2) is placed in a vertical mill to pulverize, and then passed through a 180-mesh sieve to make a powder product with a particle size (equivalent partic...

Embodiment 2

[0066] Embodiment 2 A kind of plane powder coating that is used for thermos cup surface spraying

[0067] Formula: GH-2208 60%, XL552 3.2%, NW-5 4%, GA-1 17.7%, GLP588 0.8%, titanium dioxide 7%, iron yellow 1.5%, iron red 2.0%, carbon black 0.2%, 701B 1.0 %, HY-KYZ01 1.6%, benzoin 0.3%, polytetrafluoroethylene wax powder 0.7%.

[0068] Preparation method: the specific steps are:

[0069] (1) Weigh GH-2208, XL552, NW-5, GA-1, GLP588, titanium dioxide, iron yellow, iron red, carbon black, 701B, HY-KYZ01, Benzoin and polytetrafluoroethylene wax powder were placed in a high-speed mixer and mixed for 5 minutes to obtain a mixture;

[0070] (2) extruding the mixture obtained in step (1) in a twin-screw melting extruder at a temperature of 105°C to obtain an extrudate;

[0071] (3) Put the extruded material obtained in step (2) into a vertical mill for pulverization, and pass through a 180-mesh sieve to make a powder product with a particle size (equivalent particle size D50) of 4...

Embodiment 3

[0073] Embodiment 3 A kind of plane powder coating that is used for thermos cup surface spraying

[0074] Formula: GH-2208 70%, T-105M 3.9%, NW-5 4.9%, Silica Powder 8.4%, Modaflow PowderⅢ / 2000 1.0%, Titanium Dioxide 3%, Iron Yellow 0.6%, Carbon Black 0.4%, WK701 1.0% , DP3329-1 4%, HY-KYZ011.5%, benzoin 0.5%, 168 0.3%, PTFE wax powder 0.5%.

[0075] Preparation method: the specific steps are:

[0076] (1) Weigh GH-2208, T-105M, NW-5, silicon micropowder, Modaflow PowderⅢ / 2000, titanium dioxide, iron yellow, carbon black, WK701, DP3329- 1. HY-KYZ01, benzoin, 168 and polytetrafluoroethylene wax powder were placed in a high-speed mixer and mixed for 5 minutes to obtain a mixture;

[0077] (2) extruding the mixture obtained in step (1) in a twin-screw melting extruder at a temperature of 110°C to obtain an extrudate;

[0078] (3) The extruded material obtained in step (2) is placed in a vertical mill for pulverization, and then passed through a 180-mesh sieve to make a powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com