Modified composite nanofiber membrane of cardanol and preparation method and application of membrane on enzyme immobilization

A technology of composite nanofibers and cardanol, which is applied in the direction of immobilization on/in organic carriers, fiber chemical characteristics, fiber treatment, etc., can solve the problems of low enzyme immobilization efficiency and insufficient membrane toughness, and achieve molecular weight increase, The effect of fixed action enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

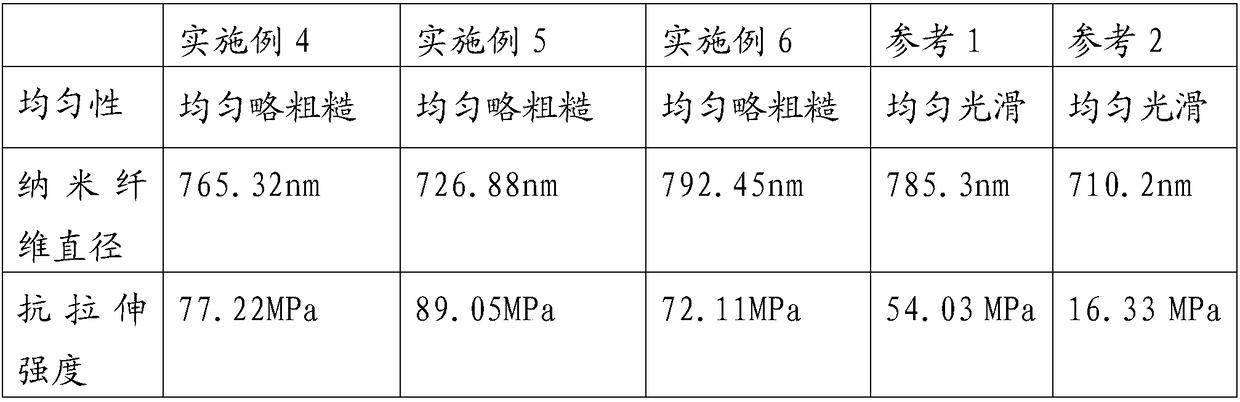

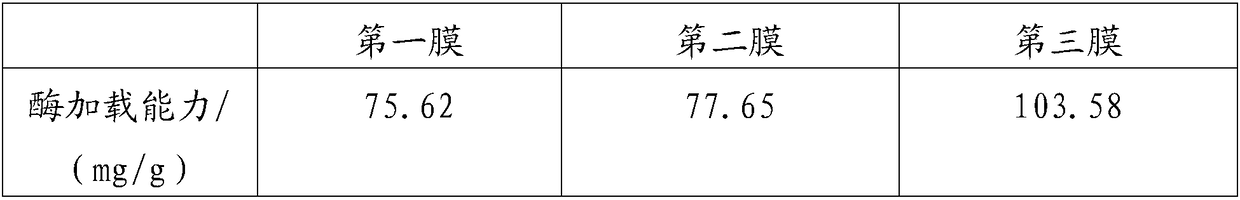

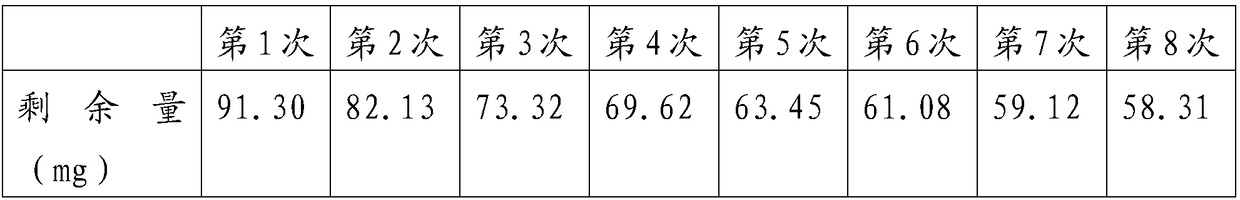

Examples

Embodiment 1

[0027] The cardanol-modified composite nanofiber membrane that this embodiment provides is prepared by the raw material of following weight ratio:

[0028] β-Hydroxyethyl Methacrylate 50, Methyl Acrylate 40, Cardanol 160, Epichlorohydrin 50, Benzyltriethylammonium Chloride 12, Potassium Permanganate 21, Toluene 120, Hordein 55, Oxidized sodium alginate 100, N-N dimethylformamide 100, glacial acetic acid 60, sodium hydroxide 80, water 300.

Embodiment 2

[0030] The cardanol-modified composite nanofiber membrane that this embodiment provides is prepared by the raw material of following weight ratio:

[0031] β-Hydroxyethyl Methacrylate 100, Methyl Acrylate 50, Cardanol 230, Epichlorohydrin 65, Benzyltriethylammonium Chloride 20, Potassium Permanganate 32, Toluene 250, Hordein 100, Oxidized sodium alginate 200, N-N dimethylformamide 300, glacial acetic acid 160, sodium hydroxide 150, water 600.

Embodiment 3

[0033] The cardanol-modified composite nanofiber membrane that this embodiment provides is prepared by the raw material of following weight ratio:

[0034] β-Hydroxyethyl Methacrylate 75, Methyl Acrylate 45, Cardanol 195, Epichlorohydrin 58, Benzyltriethylammonium Chloride 16, Potassium Permanganate 26, Toluene 185, Hordein 80, Oxygenated sodium alginate 150, N-N dimethylformamide 200, glacial acetic acid 110, sodium hydroxide 115, water 450.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com