Carbon-coated tungsten disulfide material and preparation method thereof as well as the application thereof as sodium ion battery negative electrode material

A technology of carbon coating and nickel salt, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as volume expansion and structural collapse, and achieve the effects of low cost, stable structure, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Ni(DMG) 2 Preparation: Dissolve 2.00g of dimethylglyoxime in 200mL of ethanol as solution A, 2.04g of NiCl 2 ·6H 2 O was dissolved in 50mL deionized water and recorded as solution B, and the pH value was adjusted to 8.5. Under magnetic stirring, add A dropwise to B, and continue stirring for 5 minutes after the dropwise addition, and keep the temperature below 5°C throughout the process. After the obtained product was washed several times with deionized water and ethanol, it was vacuum-dried at 80°C for 12 hours to obtain red Ni(DMG) 2 .

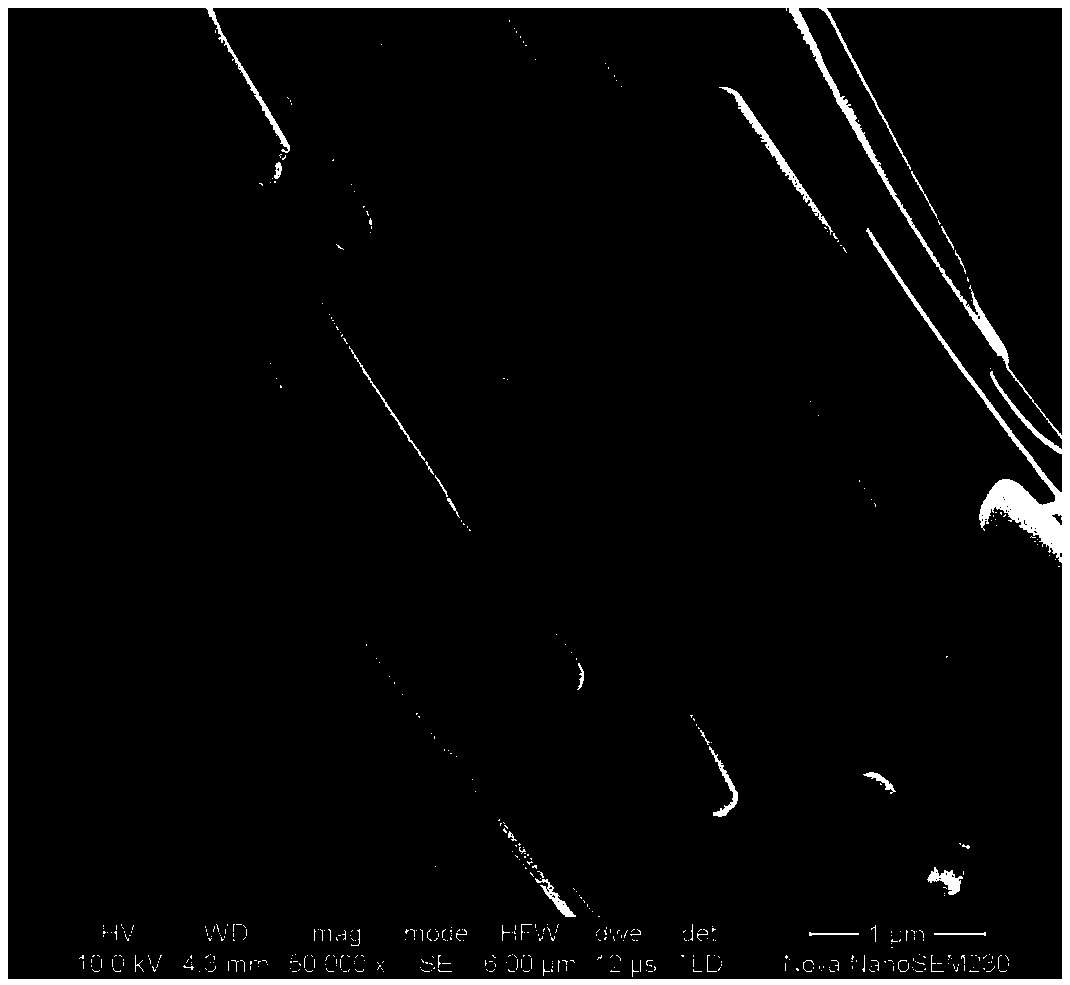

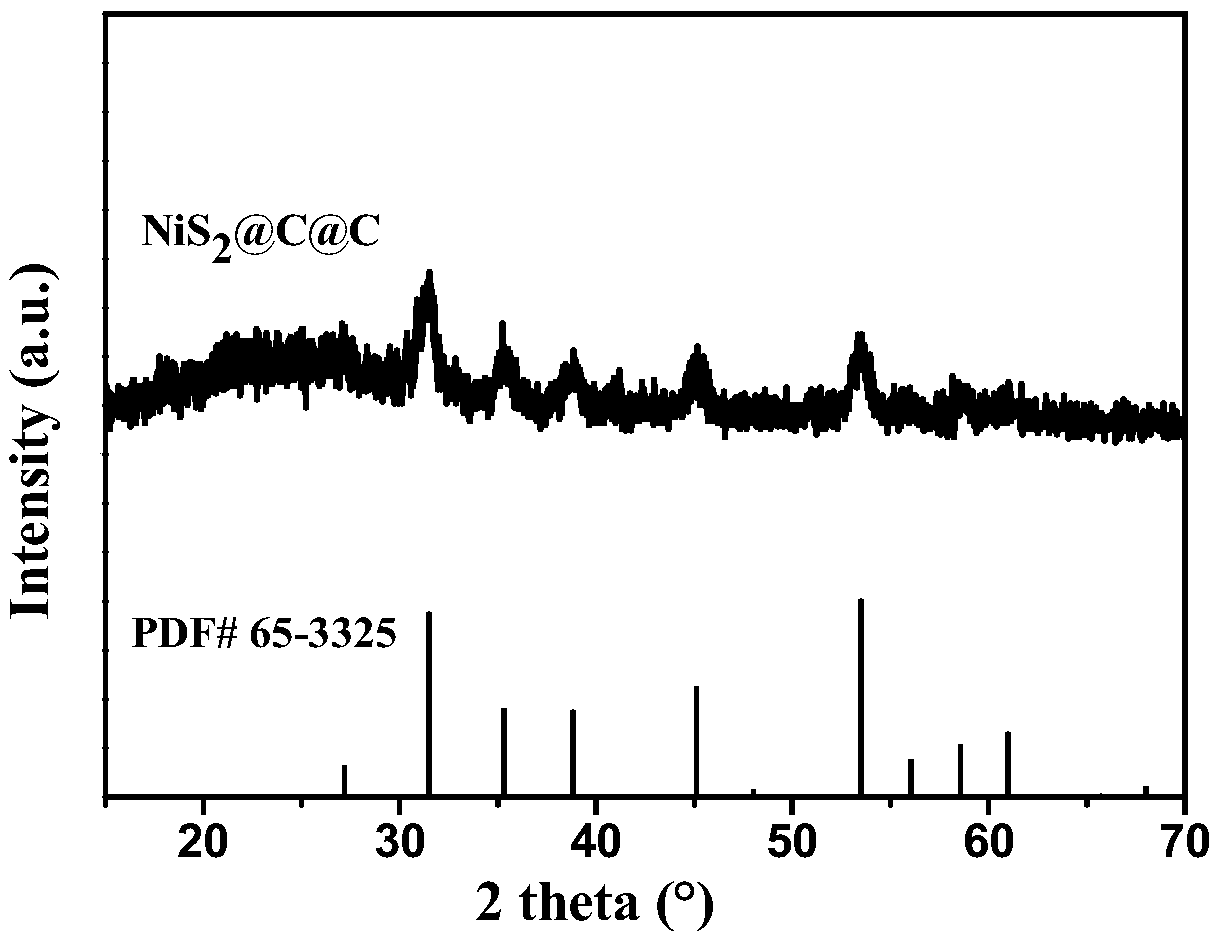

[0042] NeS 2 : 0.2g rod-shaped Ni(DMG) 2 Mix with 0.4g sublimated sulfur in a mortar and grind for 20min, then place in a magnetic boat, under N 2 Under protected conditions, at 5°C min -1 The rate is raised to 300°C for 1h, and then at 2°C min -1 The rate is raised to 500 °C for 2 h to obtain carbon / NiS 2 composite material. The composite material is not a carbon-coated material, but a mixed material of carbon and nickel di...

Embodiment 1

[0044] Ni(DMG) 2 Preparation: Dissolve 2.00g of dimethylglyoxime in 200mL of ethanol as solution A, 2.04g of NiCl 2 ·6H 2 O was dissolved in 50mL deionized water and recorded as solution B, and the pH value was adjusted to 8.5. Under magnetic stirring, add A dropwise to B, and continue stirring for 5 minutes after the dropwise addition, and keep the temperature below 5°C throughout the process. After the obtained product was washed several times with deionized water and ethanol, it was vacuum-dried at 80°C for 12 hours to obtain red Ni(DMG) 2 .

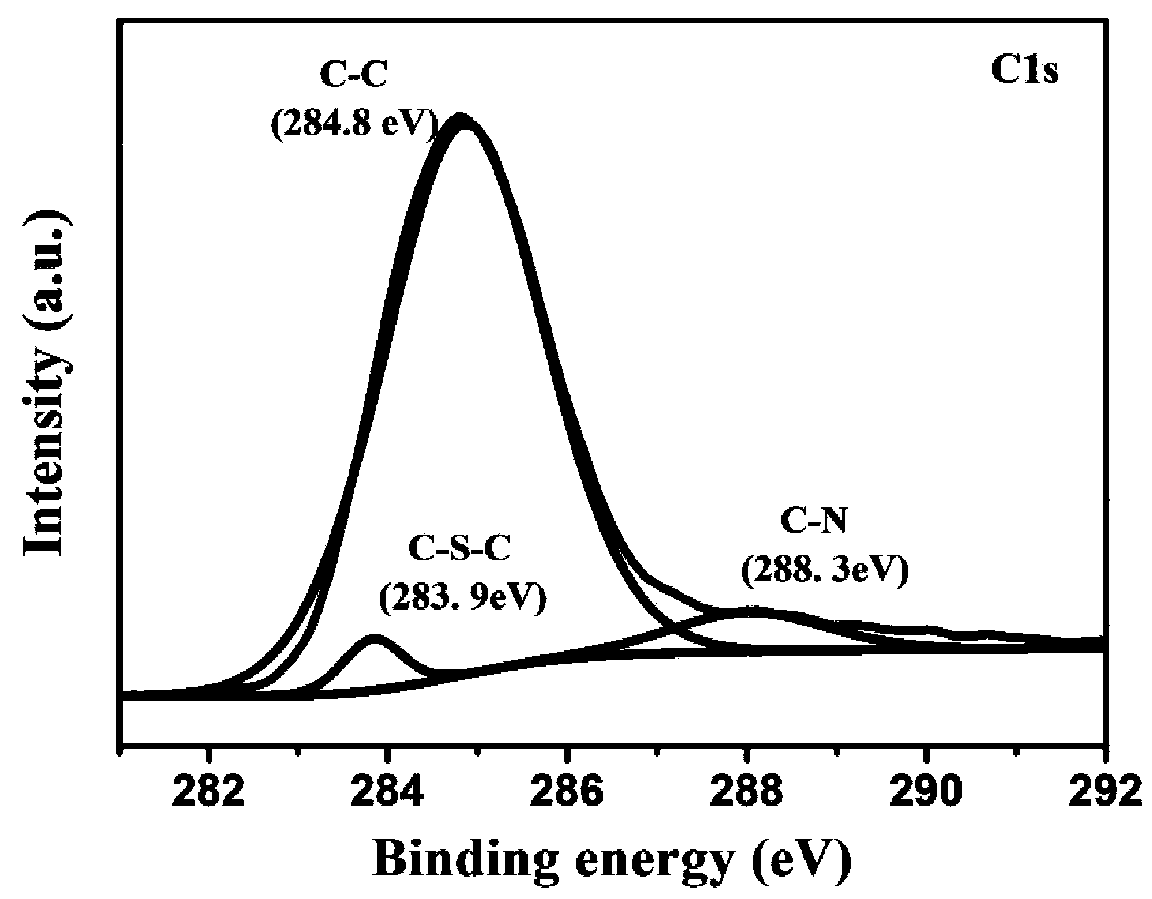

[0045] Carbon coated NiS 2 Preparation: Dissolve 0.9313g aniline and 0.75g tartaric acid in 150mL deionized water, add 0.9g Ni(DMG) 2 , after stirring for 30 min under ice bath conditions, add 50 mL of 0.2 mol / L ammonium persulfate solution pre-placed in ice bath, continue stirring for 6 h under ice bath conditions, and wash the obtained product several times with deionized water and ethanol , after vacuum drying at 80℃ for 12h,...

Embodiment 2

[0047] Ni(DMG) 2 Preparation: Dissolve 2.00g of dimethylglyoxime in 200mL of ethanol as solution A, 2.04g of NiCl 2 ·6H 2 O was dissolved in 50mL deionized water and recorded as solution B, and the pH value was adjusted to 9.0. Under magnetic stirring, add A dropwise to B, and continue stirring for 5 minutes after the dropwise addition, and keep the temperature below 5°C throughout the process. After the obtained product was washed several times with deionized water and ethanol, it was vacuum-dried at 80°C for 12 hours to obtain red Ni(DMG) 2 .

[0048] Carbon coated NiS 2 Preparation: Dissolve 0.9313g aniline and 0.75g tartaric acid in 150mL deionized water, add 0.9g Ni(DMG) 2 , after stirring for 30 min under ice bath conditions, add 50 mL of 0.2 mol / L ammonium persulfate solution pre-placed in ice bath, continue stirring for 6 h under ice bath conditions, and wash the obtained product several times with deionized water and ethanol , after vacuum drying at 80℃ for 12h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com