Integrated catalysis system based on TiO2 nanotube photocatalyst and degrading treatment method of integrated catalysis system

A technology of integrating catalytic system and photocatalyst is applied in the field of integrated catalytic system based on TiO2 nanotube photocatalyst and its degradation treatment. Achieve the effect of reducing preparation steps and equipment costs, eliminating solution stirring, and solving the narrow spectral response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

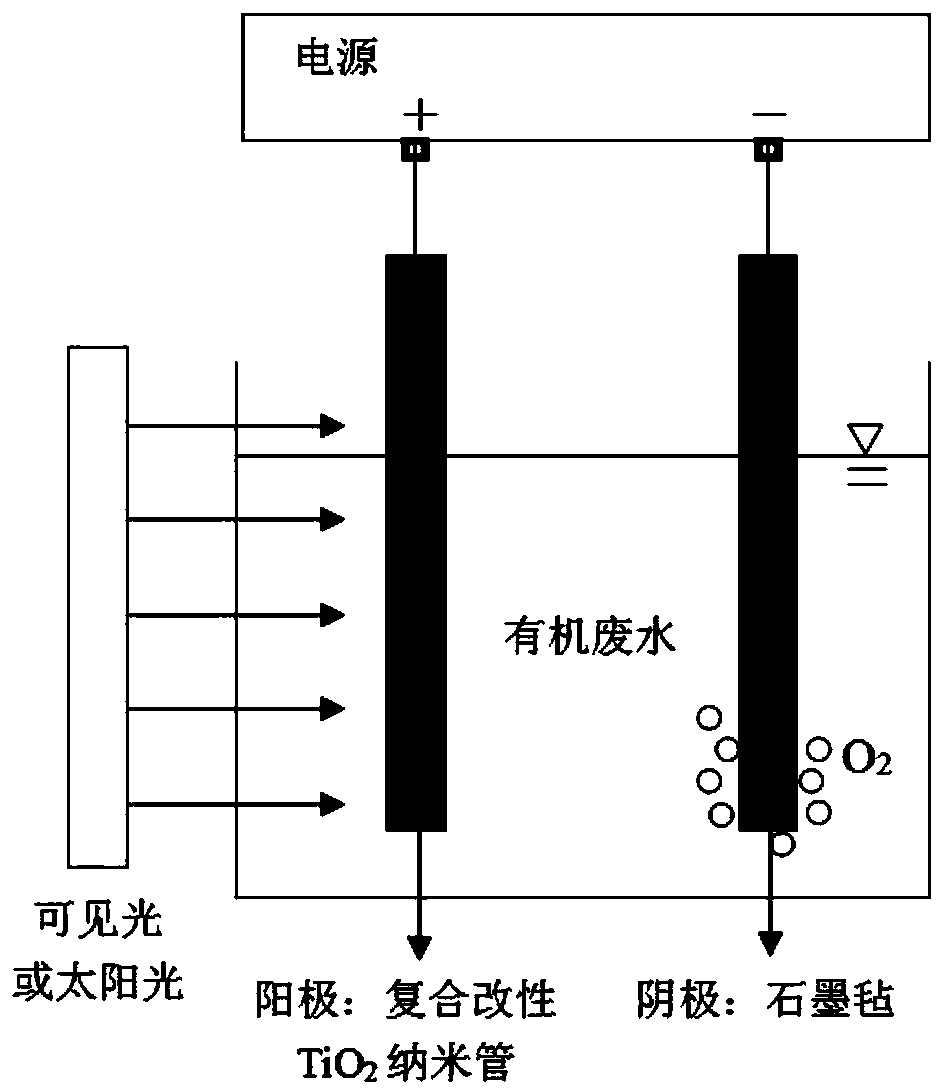

[0044] 1. This embodiment is based on TiO 2 Integrated catalytic systems of nanotube photocatalysts, such as figure 1 shown, including composite modified TiO 2 Nanotubes, visible light sources or sunlight, electrocatalytic devices, oxygenation pumps. Its construction and degradation processing methods are as follows:

[0045] (1) Take the amaranth azo dye with a concentration of 200mg / L as the simulated organic wastewater, mix 100mL organic wastewater with FeSO 4 ·7H 2 O is added to the transparent reaction vessel to form Fe 2+ For organic wastewater with a concentration of 0.03mmol / L, adjust its pH value to 6 with hydrochloric acid or ammonia water;

[0046] (2) Electrocatalytic device with composite modified TiO 2 The nanotube is used as the anode, and the porous fibrous graphite felt is cut to resemble TiO 2 The strip of the nanotube sample is used as the cathode, and both the anode and the cathode are inserted into the above-mentioned Fe-containing 2+ In the organi...

Embodiment 2

[0064] 1. This embodiment is based on TiO 2 The integrated catalytic system of nanotube photocatalyst differs from Example 1 in that: Tetrabromobisphenol A with a concentration of 20mg / L is used as the simulated organic wastewater, the pH value is adjusted to 7, the aeration rate is 4L / min, and the degradation time for 50min.

[0065] 2. Composite modified TiO in the integrated catalytic system of this example 2 The preparation method of nanotube differs from embodiment one in that:

[0066] In step (1), the amount of TiN powder is 3.5 mol% of the titanium sponge.

[0067] In step (2), the NaBF in the electrolyte 4 The dosage is 0.4wt%, and the oxidation reaction time is 30h.

Embodiment 3

[0069] 1. This embodiment is based on TiO 2 The integrated catalytic system of nanotube photocatalyst differs from Example 1 in that: tetracycline with a concentration of 20mg / L is used as the simulated organic wastewater, the pH value is adjusted to 7, the aeration rate is 4L / min, and the degradation time is 60min.

[0070] 2. Composite modified TiO in the integrated catalytic system of this example 2 The preparation method of nanotube differs from embodiment one in that:

[0071] In step (2), the NaBF in the electrolyte 4 Its usage is 0.4wt%.

[0072] In step (3), the concentration of palladium ions in the impregnated mixed solution is 0.004mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com