Processing method for intelligent hydrogel using starch nano-particles as framework

A processing method and nano-starch technology, applied in the direction of nano-technology, can solve the problems of toxicity, cumbersome process, and inability to enzymatically degrade, etc., and achieve the effects of easy operation, controllable reaction conditions, and improved bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

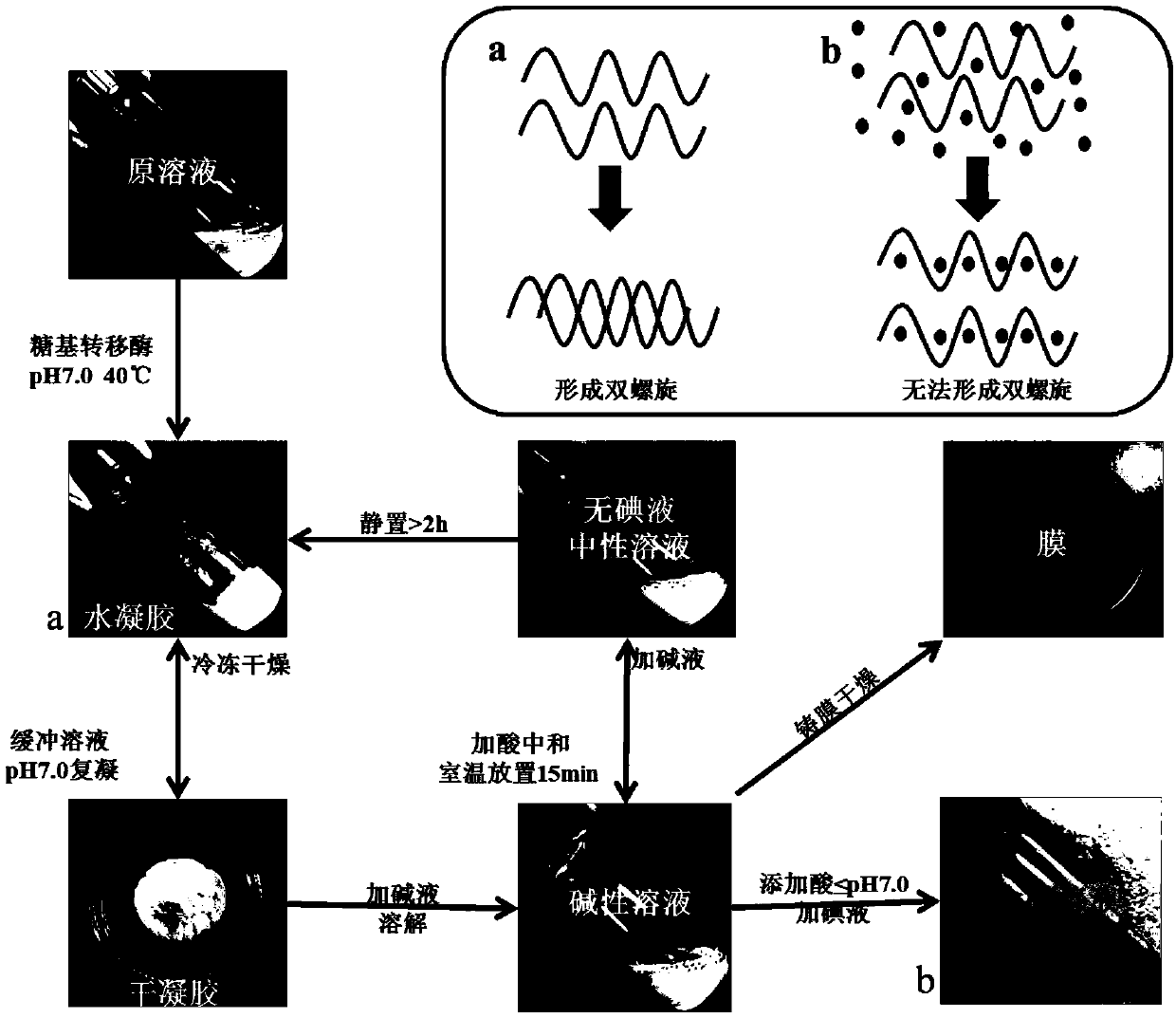

Method used

Image

Examples

Embodiment 1

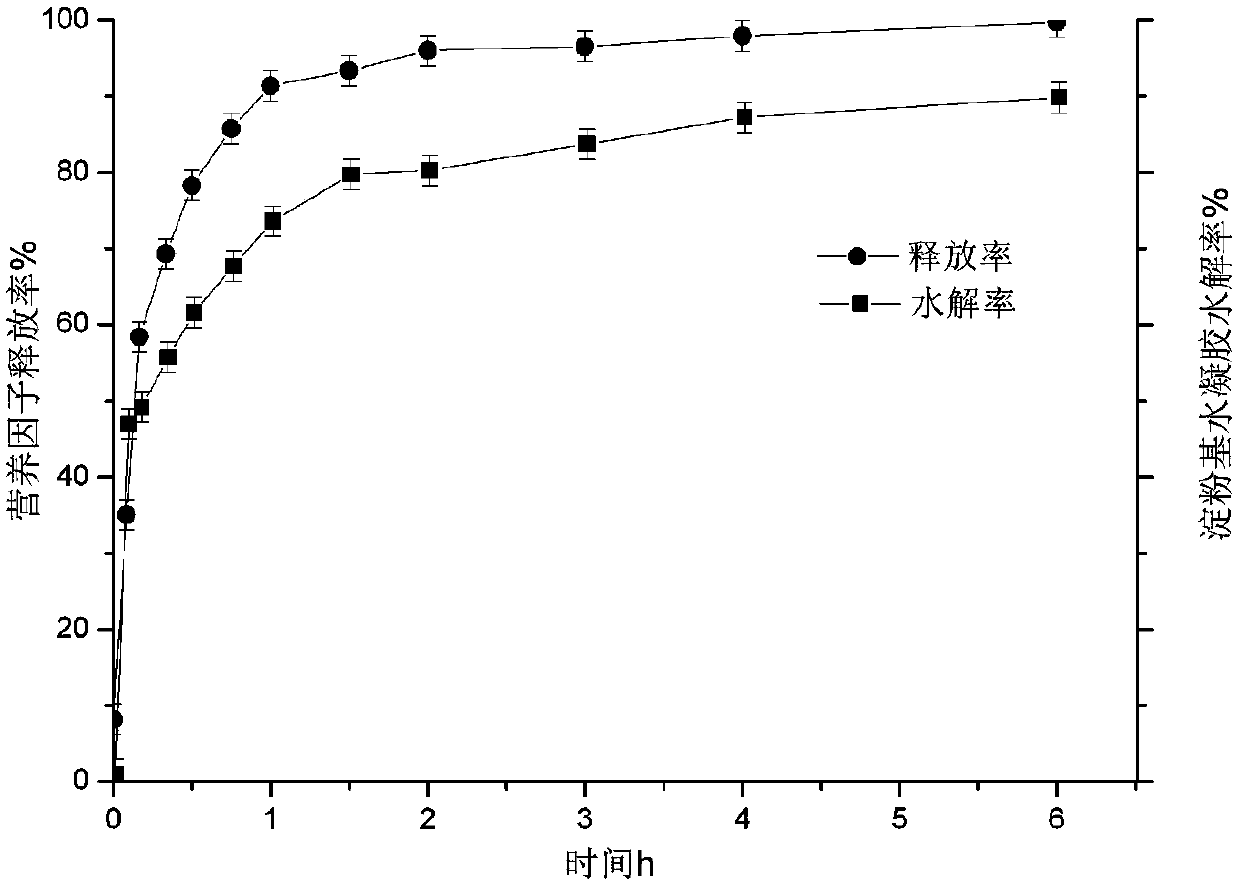

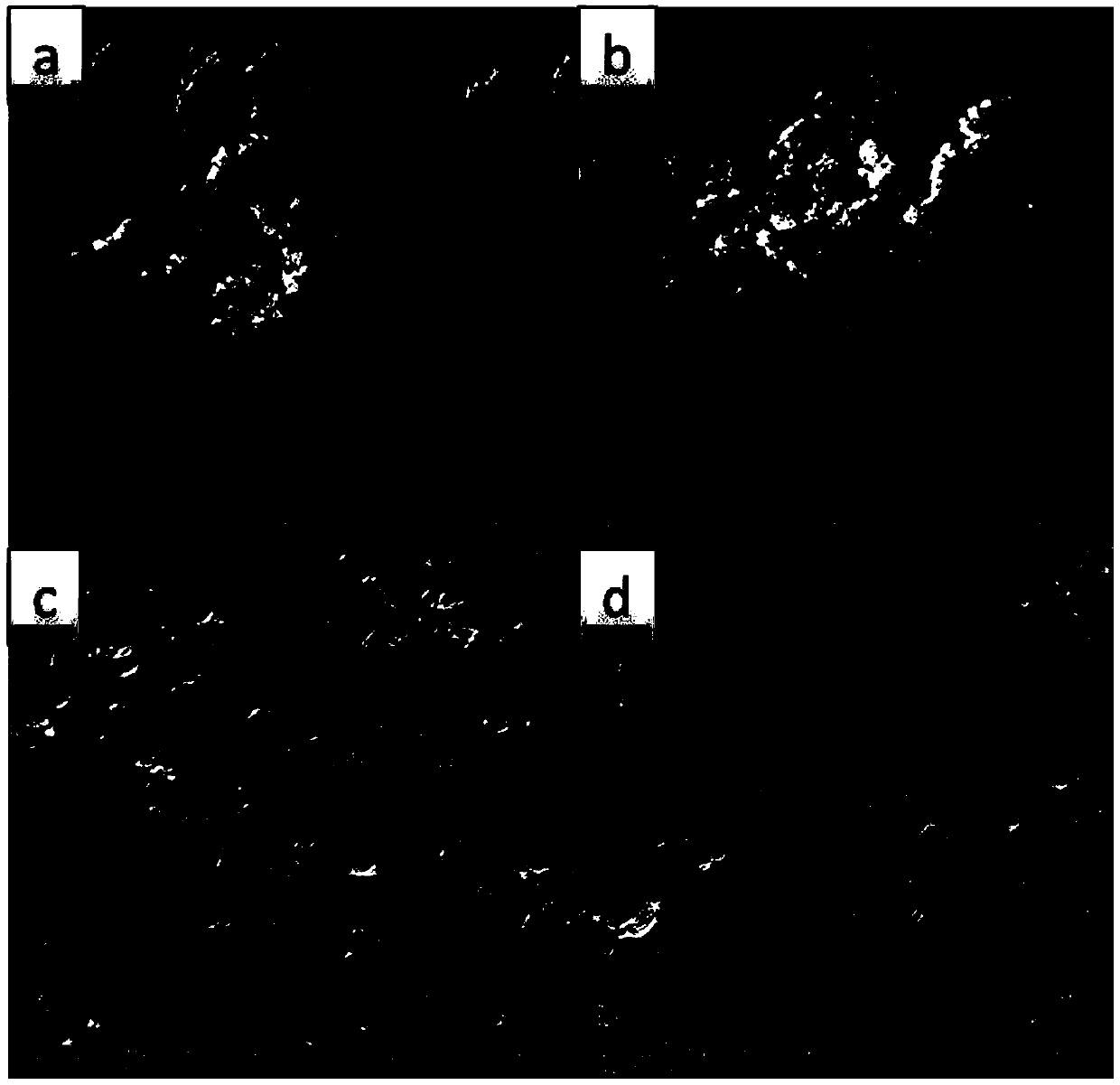

[0031] 10.0 mg of nano-starch particles were dissolved in Tris-HCl buffer solution (50 mmol / L, pH 7.0) to prepare a homogeneous solution with a mass concentration of 0.2%. Gelling reaction: the solution was sonicated for 15 minutes, then 50 mg of glucosyl donor molecules and 80 U of glycosyltransferase were added, stirred evenly, and reacted at a constant temperature of 40° C. for 24 hours. Place it at room temperature for 6h to cool, and let it stand to form a gel. The gel strength of the smart hydrogel is above 235.67g. The release rate of nutrient components through enzymatic reaction reaches 98.2%. Repeated washing with distilled water and freeze-drying can obtain xerogel. The xerogel can be re-coagulated after absorbing water, and the number of repeated gelation can reach 5 times.

[0032] Wherein, the assay method of gel strength: use physical property analyzer to hydrogel gel strength analysis; Phosphate buffered saline solution at pH 7.0, 290units / ml of α-amylase, ...

Embodiment 2

[0038] 10.0 mg of nano-starch particles were dissolved in Tris-HCl buffer solution (50 mmol / L, pH 7.0) to prepare a homogeneous solution with a mass concentration of 0.5%. Gelling reaction: The solution was sonicated for 20 minutes, and then 80 mg of glucose-based donor molecules and 100 U of glycosyltransferase were added, stirred evenly, and reacted at a constant temperature of 40° C. for 24 hours. Place it at room temperature for 6 hours to cool, and let it stand to form a gel. The gel strength of the smart hydrogel reaches 358.38g. The release rate of nutrient components through enzymatic reaction reaches 97.7%. Repeated washing with distilled water and freeze-drying can obtain xerogel. The xerogel can be re-coagulated after absorbing water, and the number of repeated gelation can reach 5 times.

Embodiment 3

[0040] 10.0 mg of nano-starch particles were dissolved in Tris-HCl buffer solution (50 mmol / L, pH 7.0) to prepare a homogeneous solution with a mass concentration of 1.0%. Gelling reaction: The solution was sonicated for 30 minutes, then 100 mg of glucose-based donor molecules and 200 U of glycosyltransferase were added, stirred evenly, and reacted at a constant temperature of 40° C. for 24 hours. Place it at room temperature for 6 hours to cool, and let it stand to form a gel. The gel strength of the smart hydrogel reaches 397.21g. The release rate of nutrient components through enzymatic reaction reaches 97.1%. Repeated washing with distilled water and freeze-drying can obtain xerogel. The dry gel can be re-coagulated after absorbing water, and the number of repeated gelation can reach 6 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com