Method for extracting rubidium chloride from kaolin tailings

A technology of kaolin tailings and rubidium chloride, applied in the direction of improving process efficiency, etc., can solve the problems of full utilization of rubidium resources, high cost, large energy loss, etc., to achieve environmental protection, compress economic costs, reduce The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

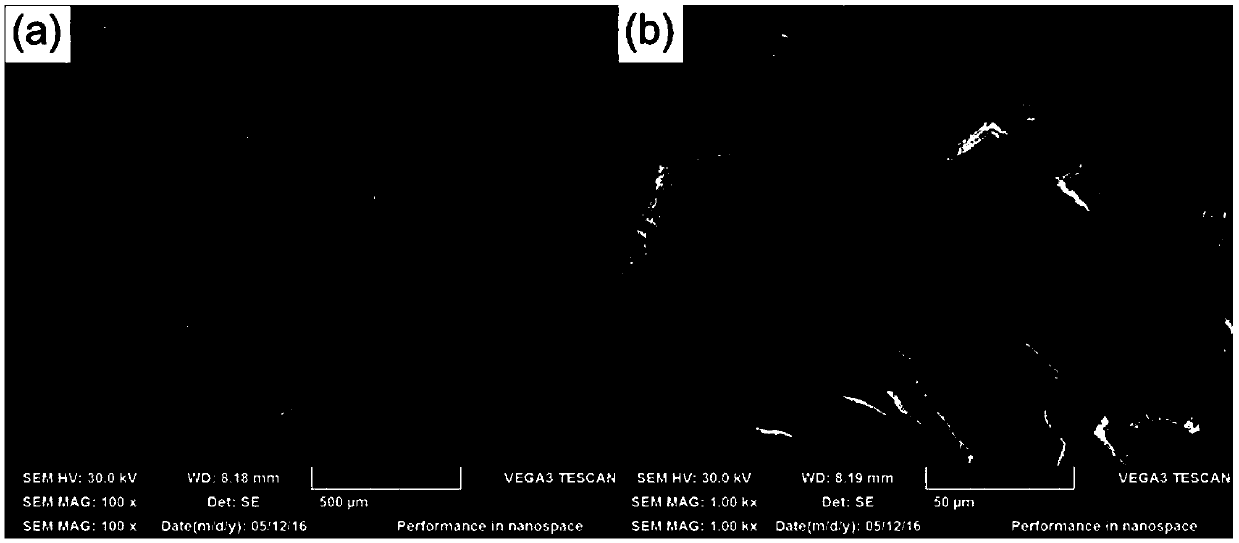

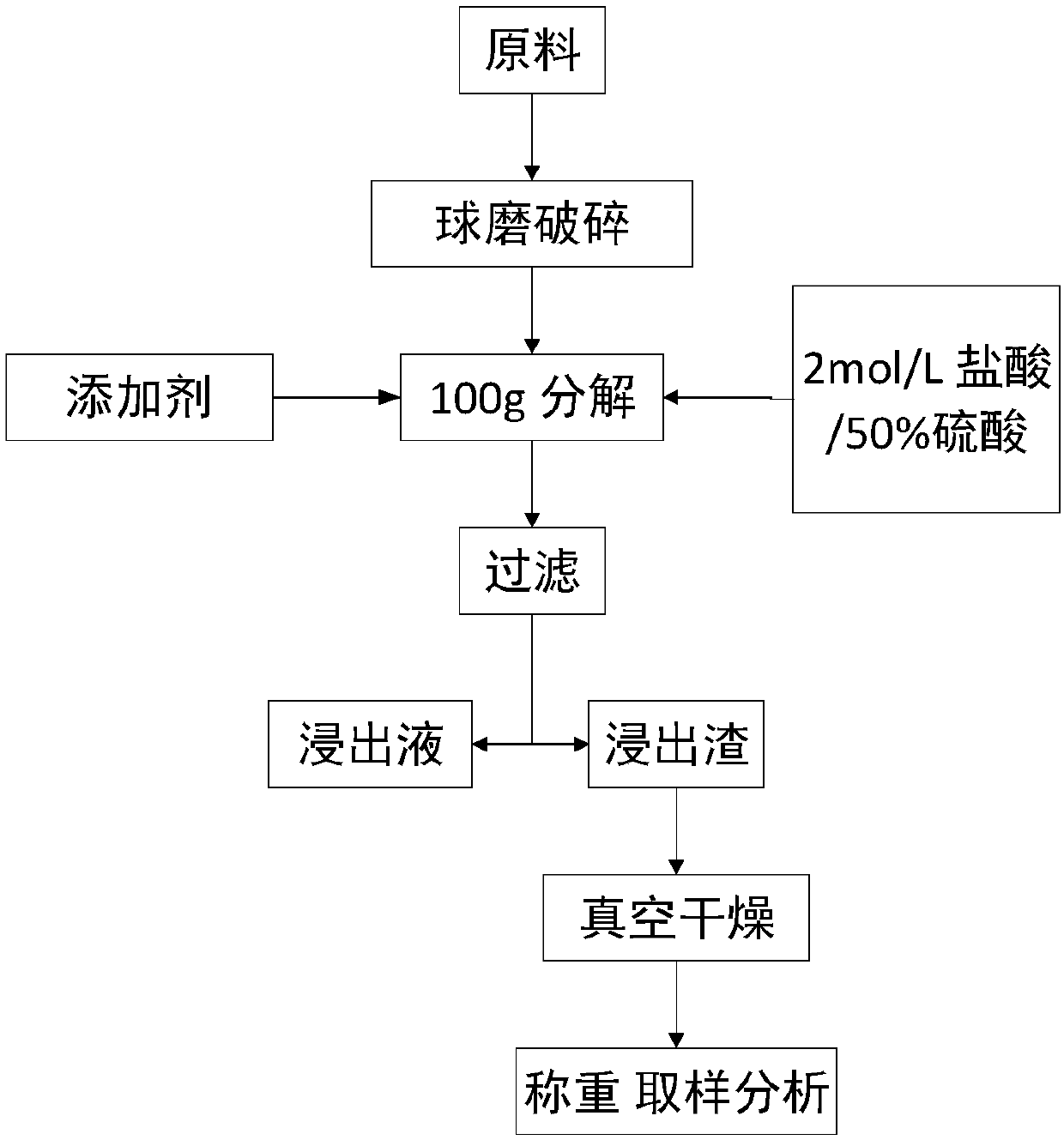

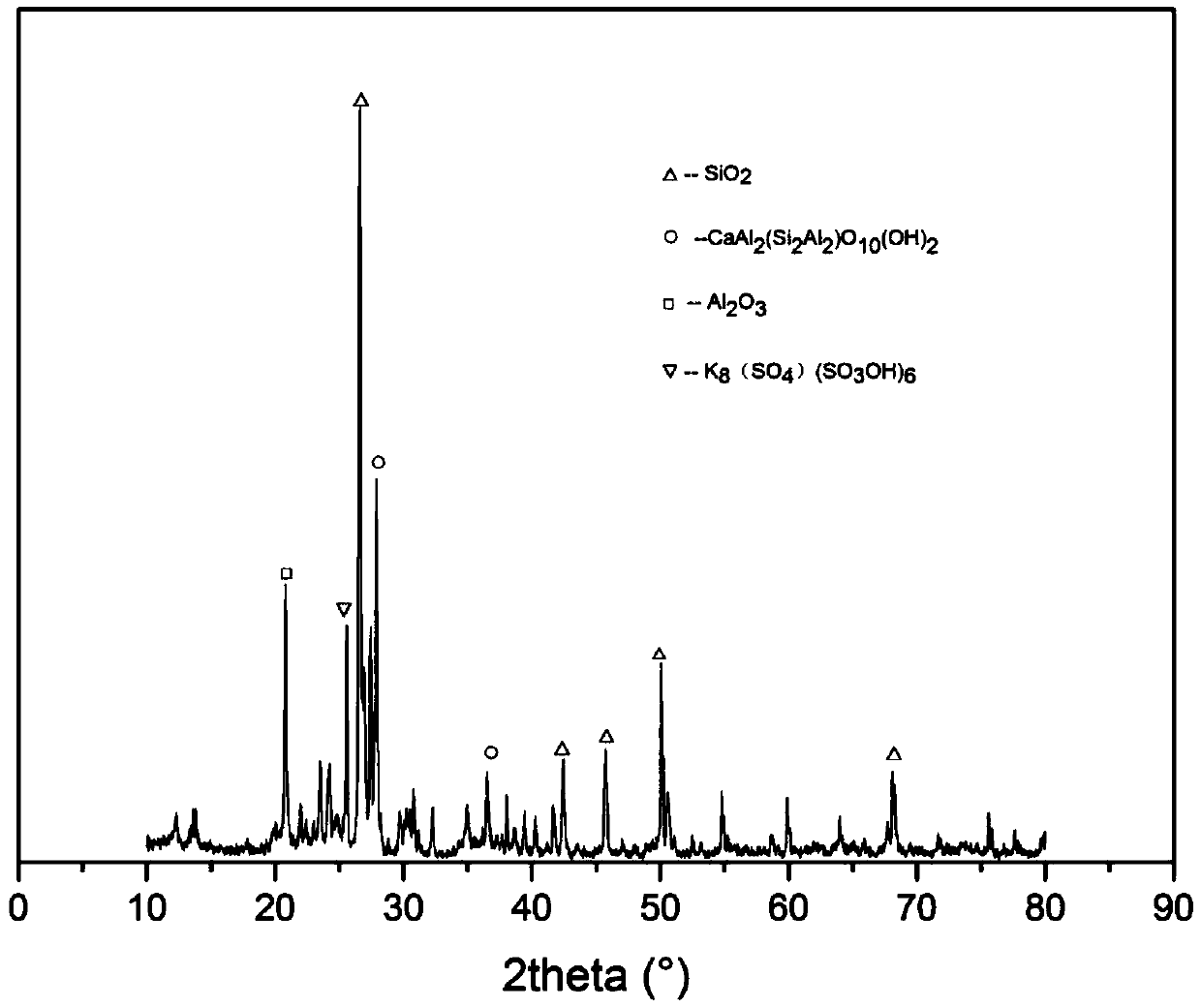

[0036] The test uses the rubidium-containing minerals produced by the beneficiation process provided by the Changsha Research Institute of Mining and Metallurgy. The ore samples are dried and then ground. The bulk density of the ore samples is 1.13g / cm 3 , the true density is 2.4g / cm 3 , the shape of the ore sample is as figure 1 As shown, the acid leaching process is as follows figure 2 As shown, the phase composition is as image 3 As shown, the ore sample contains 0.2% rubidium in the ICP analysis test of the State Key Laboratory of Powder Metallurgy Research Institute of Central South University.

[0037] The method for extracting rubidium chloride from kaolin tailings of the present embodiment may further comprise the steps:

[0038] (1) Add the ore sample into the vibrating disc mill and vibrate for 4min, pass through a 300 mesh screen to obtain -300 mesh 95% ore powder; add the leaching agent CaF 2 Carry out disc grinding and crushing, and pass through a 300-mesh s...

Embodiment 2

[0061] The difference between this embodiment and Example 1 is that in step (2), the sulfuric acid with a mass fraction of 40% is replaced by the sulfuric acid with a mass fraction of 30%. After testing and analysis, through the acid leaching operation, the leaching rate of rubidium in the mineral is 75%, most of the rubidium has been leached.

Embodiment 3

[0063] This embodiment differs from Example 1 in that step (2) replaces 15% calcium fluoride with 10% calcium fluoride. After testing and analysis, through the acid leaching operation, the rubidium leaching rate in the ore powder is 73%. %, most of the rubidium has been leached.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com