Condensation and reheating integration type smoke plume white-eliminating system

A thermal cycle system and smoke plume technology, applied in the field of flue gas treatment system at the tail of coal-fired power plants, can solve problems such as affecting the appearance and increasing the moisture content of flue gas, and achieve the effect of eliminating white plume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

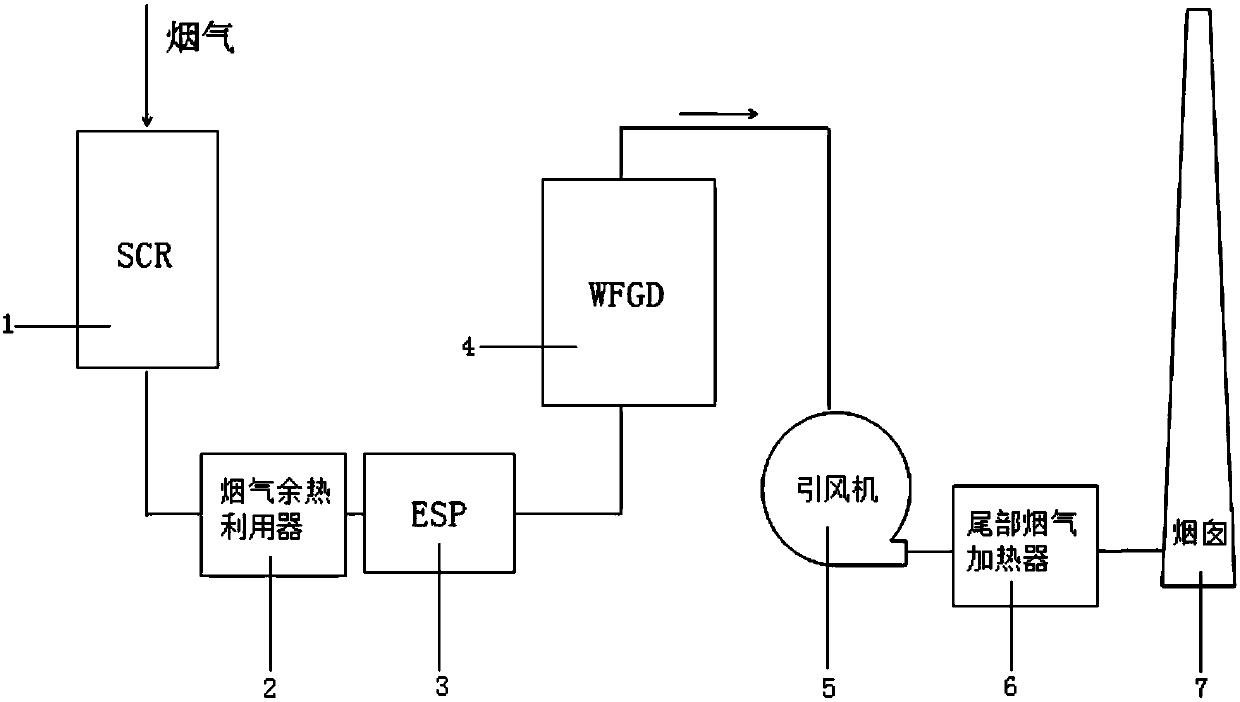

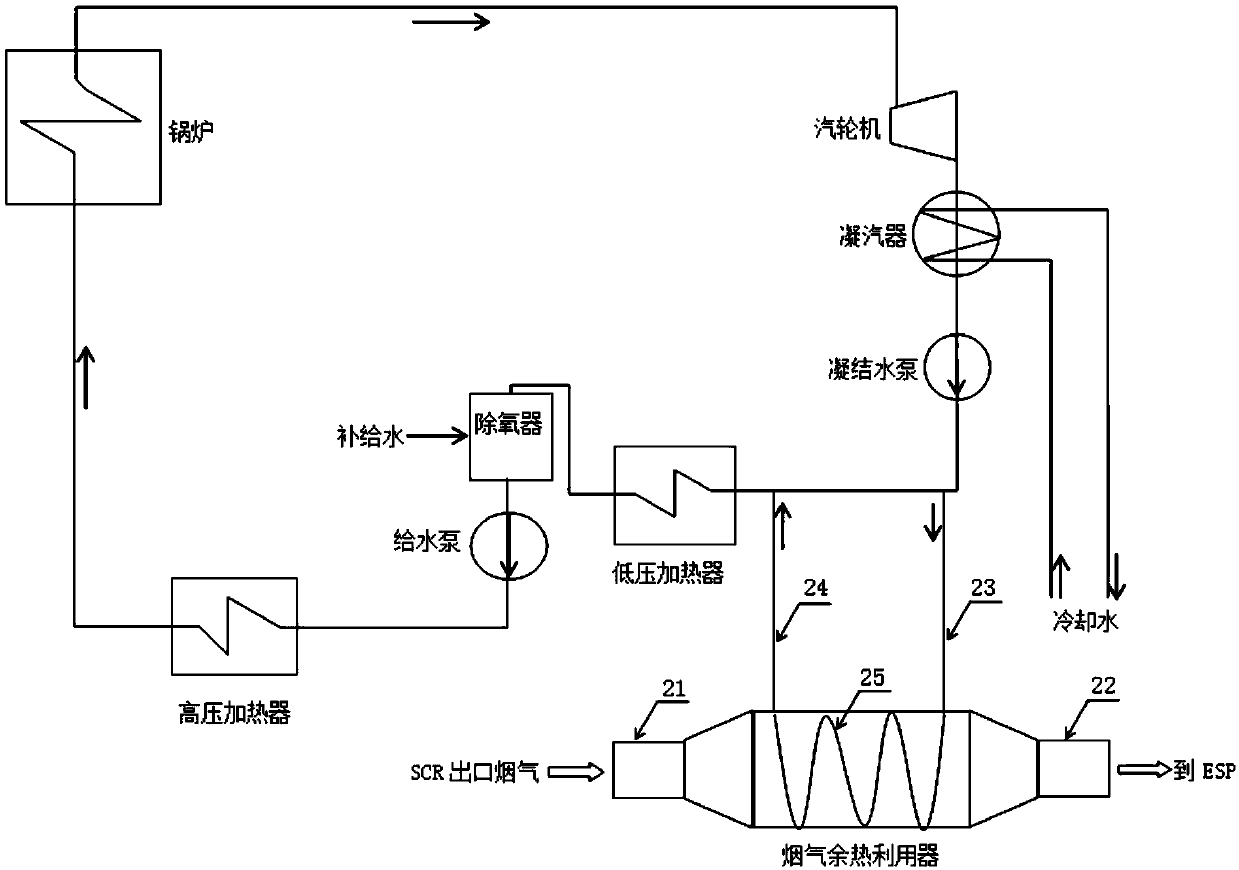

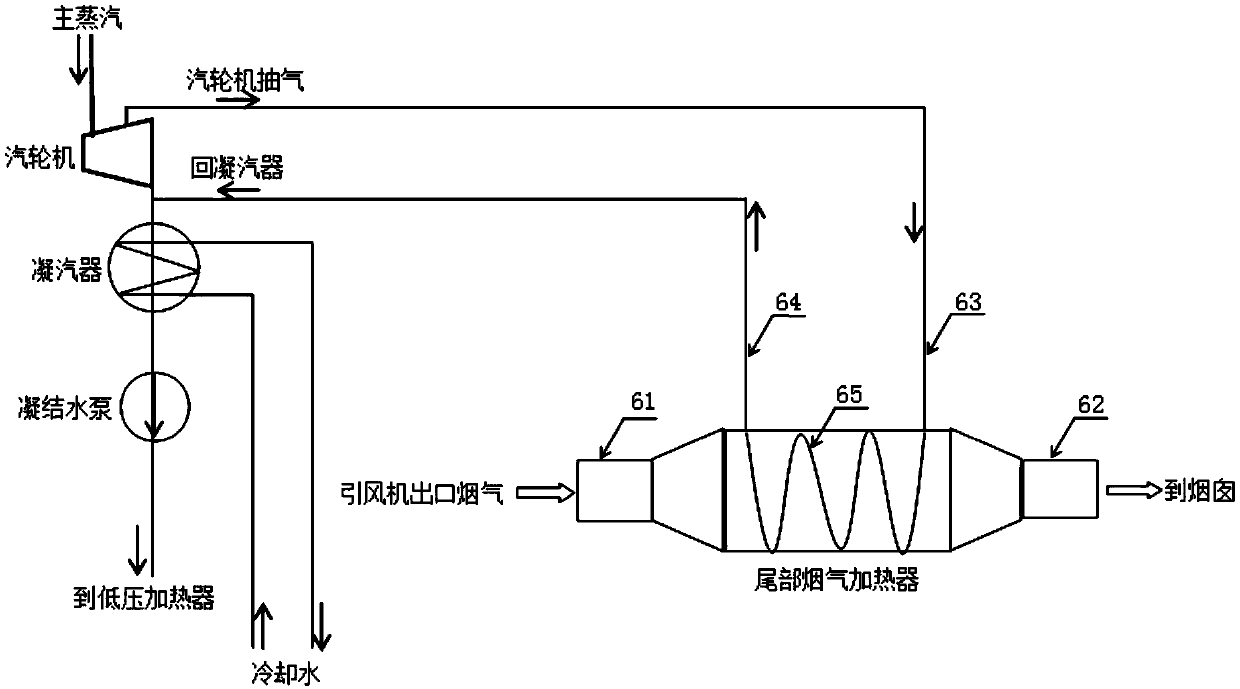

[0025] A condensation-reheating integrated plume elimination system, such as figure 1 , the system includes a denitrification device 1 connected in series, a flue gas waste heat utilization device 2 for recovering flue gas waste heat, an electrostatic precipitator 3, a wet desulfurization device 4, an induced draft fan 5, and a tail flue gas for raising the flue gas temperature. Gas heater 6 and chimney 7. The flue gas waste heat utilization device 2 includes a first flue gas inlet pipeline 21, a first flue gas outlet pipeline 22, and a first partition heat exchanger 25 inside it, and the first partition heat exchanger 25 includes a working fluid The inlet pipeline 23 and the working fluid outlet pipeline 24, the first flue gas inlet pipeline 21 is connected to the denitrification device 1, the first flue gas outlet pipeline 22 is connected to the electrostatic precipitator 3, and the working medium inlet of the first partition heat exchanger 25 The pipeline 23 and the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com