Si/C nano composite anode material as well as preparation method and application thereof

A nano-composite, anode material technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of reduced performance, unfavorable mass production, decreased capacitance density, etc., to improve electrochemical performance. performance, facilitating electron transport, reducing the effect of capacity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

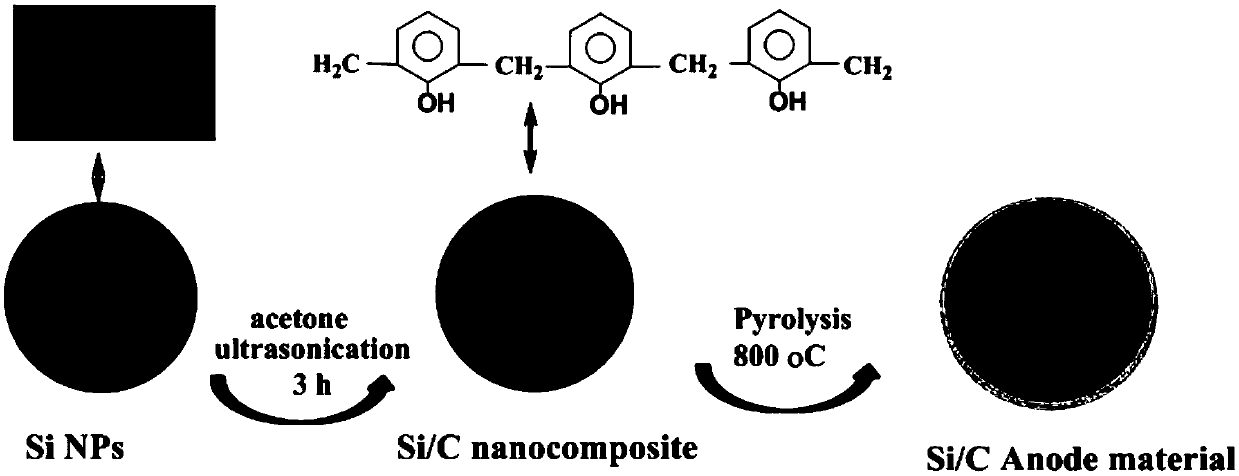

[0030] 1mol of phenol (94g), 0.85mol of formaldehyde 37% (0.69g) and 0.1mol of oxalic acid (1.45g) were dissolved in 10ml of deionized water to obtain a mixed solution, and the mixed solution was added to 250ml with a magnetic stirring bar, refluxed and condensed In a three-necked flask with a thermometer and a thermometer, heat and reflux for 1 hour under constant stirring, then add 30ml for precipitation, then pour off the upper layer, take the lower layer and distill under reduced pressure for 1 hour at 120°C; dissolve the polymer in ethanol , and then precipitated with distilled water, the purified polymer was obtained by this method, and the phenolic resin was obtained.

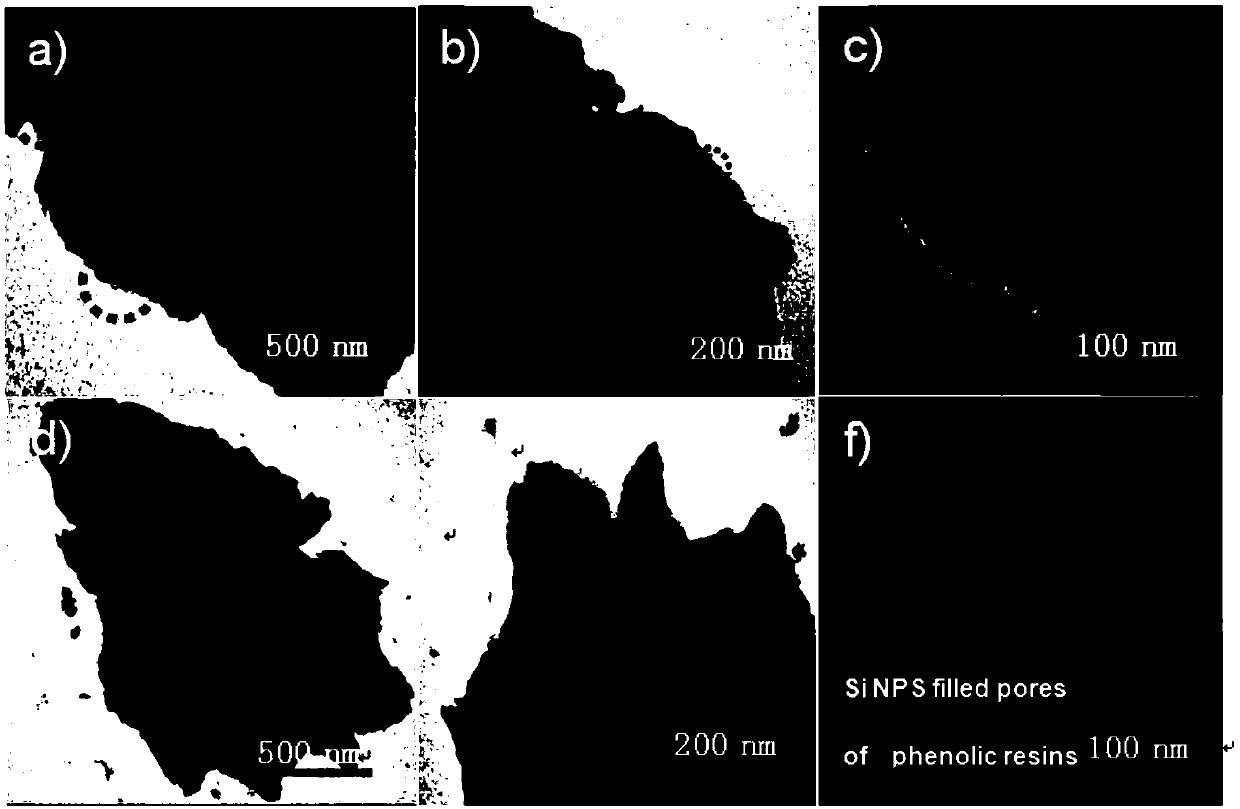

[0031] Mix 3 g of phenolic resin in 100 ml of acetone, then keep stirring until it becomes milky white, then add 1 g of silicon nanoparticles to the solution, ultrasonicate the light yellow solution at 40 °C for 3 hours, then continue stirring for 24 h, and The solution was evaporated to dryness, and the...

Embodiment 2

[0035] 1mol of phenol (94g), 0.85mol of formaldehyde 37% (0.69g) and 0.1mol of oxalic acid (1.45g) were dissolved in 10ml of deionized water to obtain a mixed solution, and the mixed solution was added to 250ml with a magnetic stirring bar, refluxed and condensed In a three-necked flask with a thermometer and a thermometer, heat and reflux for 1 hour under constant stirring, then add 30ml for precipitation, then pour off the upper layer, take the lower layer and distill under reduced pressure for 1 hour at 120°C; dissolve the polymer in ethanol , and then precipitated with distilled water, the purified polymer was obtained by this method, and the phenolic resin was obtained.

[0036] Mix 3 g of the above-mentioned phenolic resin in 100 ml of acetone, then keep stirring until it becomes milky white, then add 1 g of silicon nanoparticles to the solution, ultrasonicate the light yellow solution at 40° C. for 3 hours, then continue stirring for 24 h, The solution was evaporated to...

Embodiment 3

[0039] 1mol of phenol (94g), 0.85mol of formaldehyde 37% (0.69g) and 0.1mol of oxalic acid (1.45g) were dissolved in 10ml of deionized water to obtain a mixed solution, and the mixed solution was added to 250ml with a magnetic stirring bar, refluxed and condensed In a three-necked flask with a thermometer and a thermometer, heat and reflux for 1 hour under constant stirring, then add 30ml for precipitation, then pour off the upper layer, take the lower layer and distill under reduced pressure for 1 hour at 120°C; dissolve the polymer in ethanol , and then precipitated with distilled water, the purified polymer was obtained by this method, and the phenolic resin was obtained.

[0040] Mix 3 g of the above-mentioned phenolic resin in 100 ml of acetone, then keep stirring until it becomes milky white, then add 1 g of silicon nanoparticles to the solution, ultrasonicate the light yellow solution at 40° C. for 3 hours, then continue stirring for 24 h, The solution was evaporated to d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com