Y-doped CaMnO3 coated ternary positive electrode material and preparation method thereof

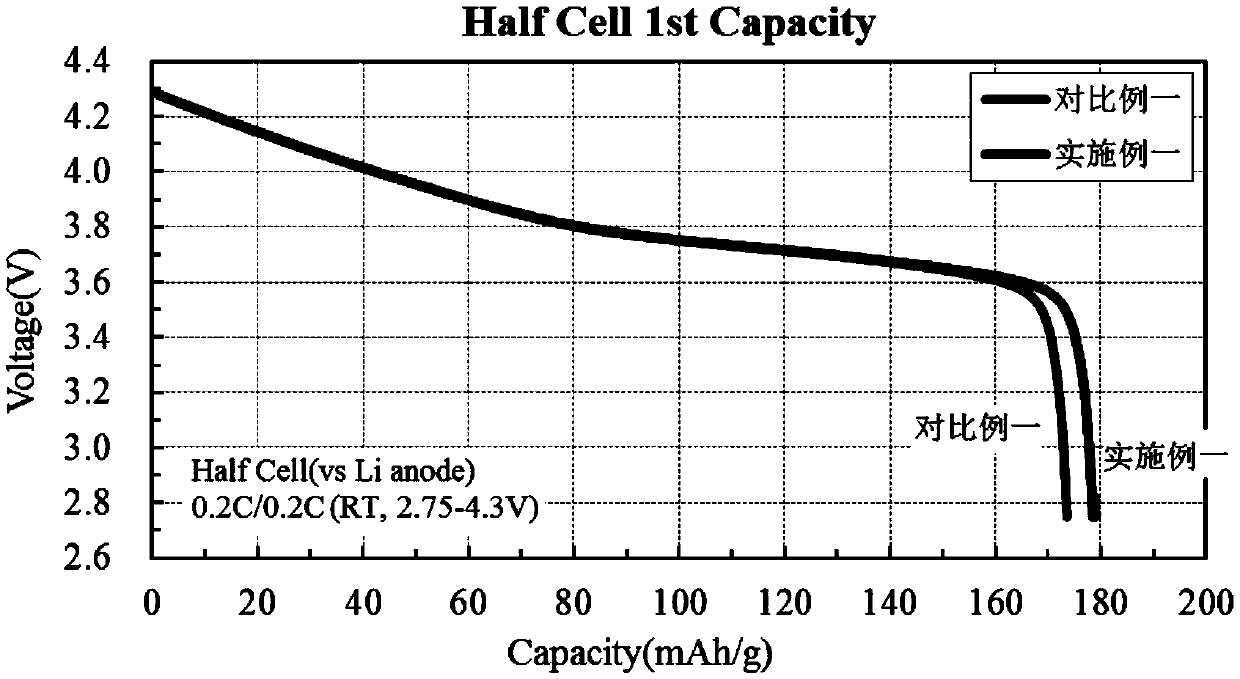

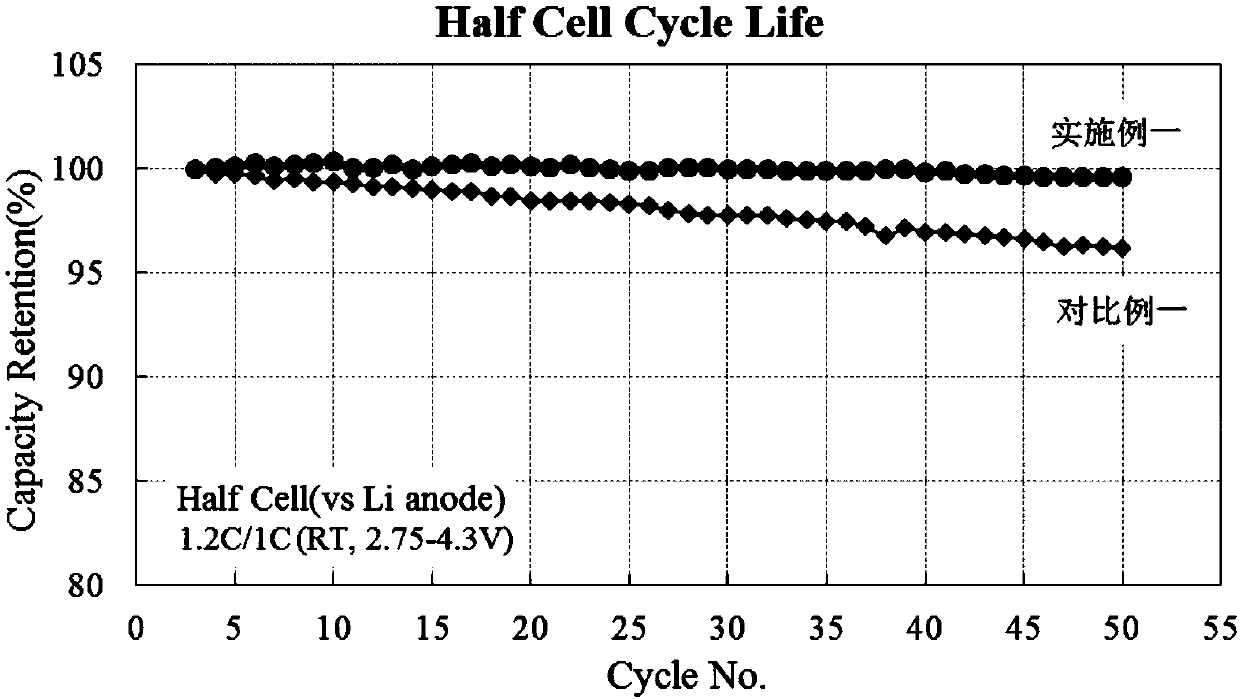

A technology of positive electrode material and ternary material, which is applied in Y-doped CaMnO3-coated ternary positive electrode material and its preparation field, can solve the problem of low conductivity of ternary positive electrode material, achieve the goal of improving conductivity and cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Y-doped CaMnO provided by the invention 3 The preparation method of the coated ternary cathode material comprises the following steps:

[0016] Step S1, the ternary material precursor Ni x co y mn 1-x-y (OH) 2 It is blended with lithium source in a certain proportion, and mixed with absolute ethanol or propanol at the same time, and then sintered, crushed, and sieved to obtain a sintered product.

[0017] In this step, the lithium source is LiOH, Li 2 CO 3 or Li 2 C 2 o 4 , the ternary material precursor and the lithium source are formulated according to the molar ratio of 1.00≤Li:(Ni+Co+Mn)≤1.10, and the mass of the ternary material precursor is 10% to 50%, adding absolute ethanol or propanol and mixing for 0.5 to 2 hours , and then sintered at 700-900°C for 5-10 hours, then crushed and sieved to obtain the primary sintered product LiNi x co y mn 1-x-y o 2 , where, 0.6≤x≤0.7, 0.1≤y≤0.2.

[0018] Step S2, dissolving the calcium source and the manganese sou...

Embodiment 1

[0027] 1) 100g ternary material precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 Prepare with LiOH according to the molar ratio of Li:(Ni+Co+Mn)=1.06, add 40g of absolute ethanol and mix for 0.5-2h, then sinter at 750°C for 8h, then pulverize and sieve to obtain the primary sintered product LiNi 0.6 co 0.2 mn 0.2 o 2 .

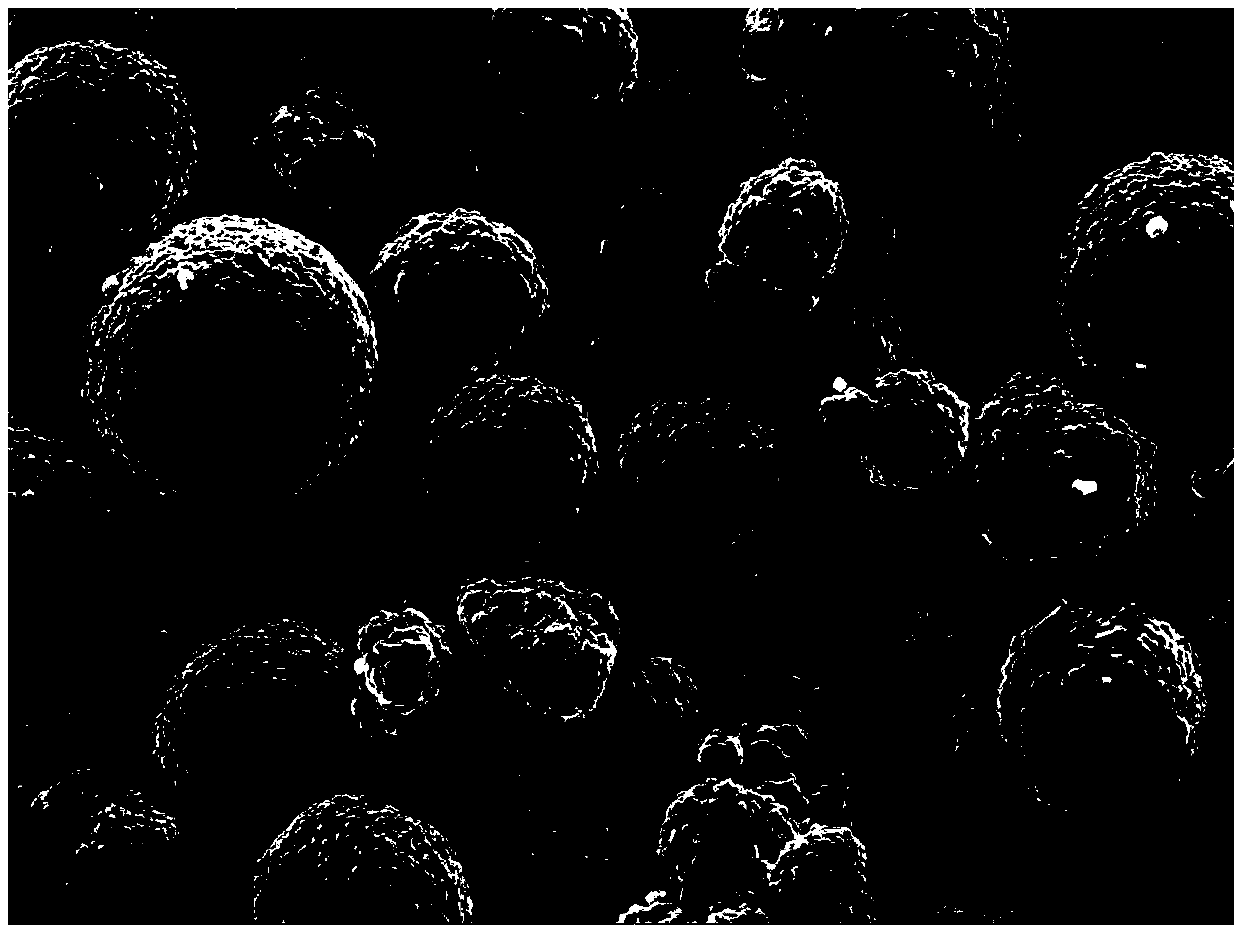

[0028] 2) Calcium carbonate and manganese oxide were dissolved in absolute ethanol according to the molar ratio of Ca:Mn=1:1, and stirred and mixed at 25°C for 2 hours to form a gel-like sol. Then the sol was sintered at 950°C for 5 hours to obtain CaMnO 3 . Finally CaMnO 3 Crush to below 200nm.

[0029] 3) Firstly, the YOH sol was diluted 10 times with ultrapure water and then mixed uniformly with the primary sintered product described in step 1), stirred and evaporated to dryness for 3 hours until the material was in powder form, and the water content on the surface of the material was 400ppm.

[0030] 4) Step 2) the pulverized CaMnO 3 Mix evenly with the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com