Copper nano-particle/black phosphorus nano-sheet composite material, preparation method and application thereof

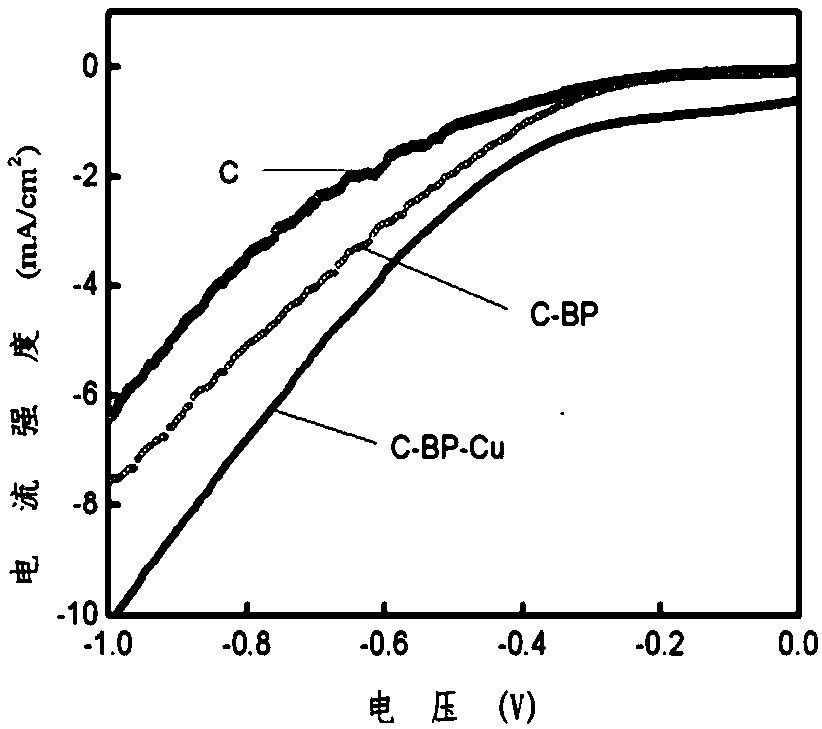

A technology of copper nanoparticles and composite materials, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of complicated experimental process and limited popularization and application, and achieve enhanced catalytic activity and enhanced catalytic performance. High performance and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

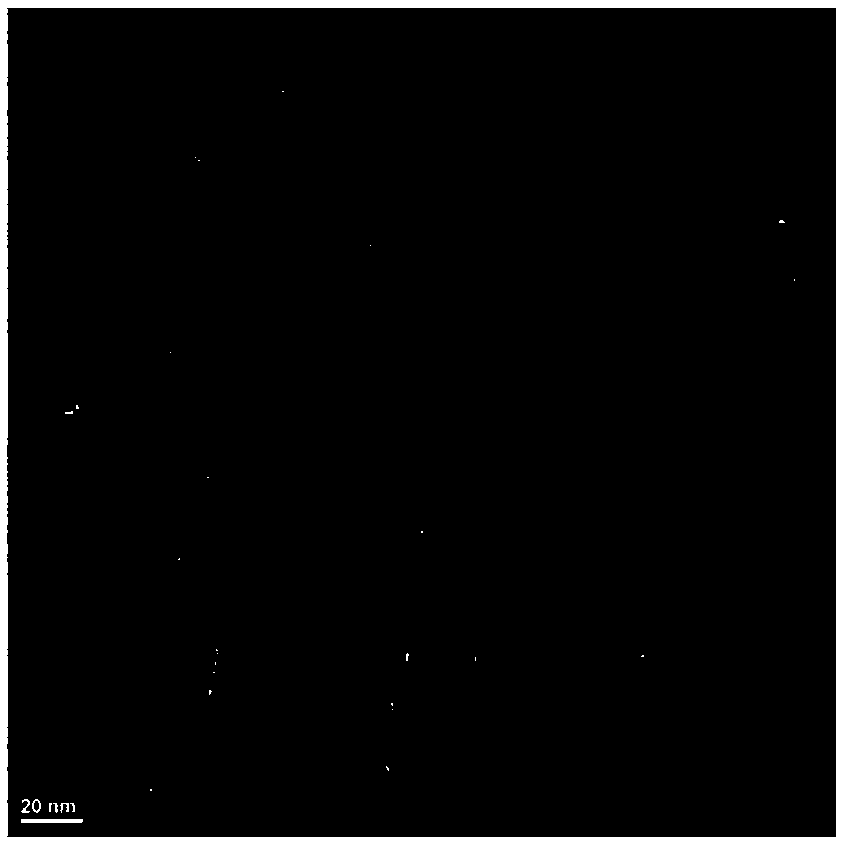

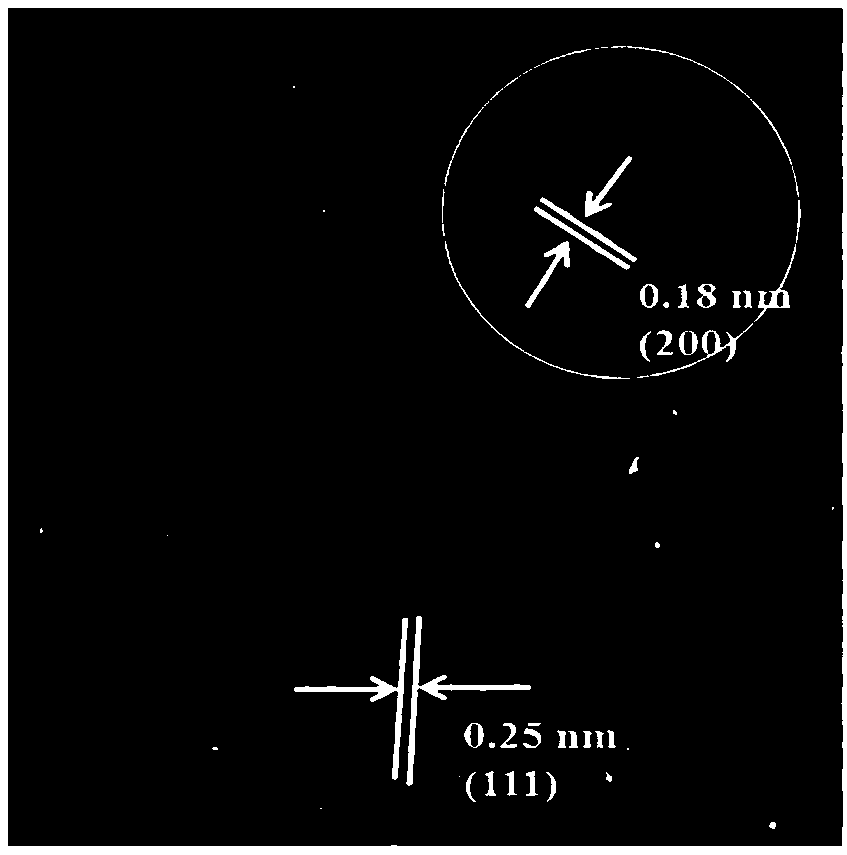

[0021] The copper nanoparticle / black phosphorus nanosheet composite material of the present invention comprises a black phosphorus nanosheet carrier and copper nanoparticles loaded on the carrier, and the particle diameter of the copper nanoparticle is 2-4 nm.

[0022] The preparation method of composite material of the present invention comprises the steps:

[0023] (1) Weigh 10 mg block black phosphorus and 10 mg sodium hydroxide and disperse them in 30 ml N-cyclohexyl-2-pyrrolidone to obtain a mixed solution for subsequent use;

[0024] (2) Put the above mixed solution into the autoclave of the supercritical device, and when the temperature of the autoclave reaches 40°C, the CO 2 Pump into the autoclave, and when the pressure of the autoclave reaches 15MPa, the system reaches a supercritical state and is maintained for 3 hours;

[0025] (3) After the reaction is over, release the CO in the autoclave 2 , cooled to room temperature, then sonicated the mixed solution for 6 h...

Embodiment 2

[0038] The copper nanoparticle / black phosphorus nanosheet composite material of the present invention comprises a black phosphorus nanosheet carrier and copper nanoparticles loaded on the carrier. The particle size of the copper nanoparticles is 2-5 nm.

[0039] The preparation method of composite material of the present invention comprises the steps:

[0040] (1) Weighing 10 mg block black phosphorus and 15 mg sodium hydroxide are dispersed in 30 ml N-cyclohexyl-2-pyrrolidone to obtain a mixed solution for subsequent use;

[0041](2) Put the mixed solution into the autoclave of the supercritical device, and when the temperature of the autoclave reaches 40°C, the CO 2 Pump into the autoclave, and when the pressure of the autoclave reaches 15MPa, the system reaches a supercritical state and is maintained for 3 hours;

[0042] (3) After the reaction is over, release the CO in the autoclave 2 , cooled to room temperature, and then the mixture was sonicated at 150W for 4 hours,...

Embodiment 3

[0046] The copper nanoparticle / black phosphorus nanosheet composite material of the present invention comprises a black phosphorus nanosheet carrier and copper nanoparticles loaded on the carrier. The particle size of the copper nanoparticles is 2-5 nm.

[0047] The preparation method of composite material of the present invention comprises the steps:

[0048] (1) Weigh 10 mg block black phosphorus and 20 mg sodium hydroxide and disperse them in 30 ml N-cyclohexyl-2-pyrrolidone to obtain a mixed solution for subsequent use;

[0049] (2) Put the mixed solution into the autoclave of the supercritical device, and when the temperature of the autoclave reaches 40°C, the CO 2 Pump into the autoclave, and when the pressure of the autoclave reaches 15MPa, the system reaches a supercritical state and is maintained for 3 hours;

[0050] (3) After the reaction is over, release the CO in the autoclave 2 , cooled down to room temperature, and then the mixture was sonicated at 120W for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com