A kind of butadiene producing bacteria and its method for producing butadiene

A technology for producing bacteria and butadiene, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, bacteria, etc., can solve the problems of high cost, low and efficient synthesis of butadiene, and no cost, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

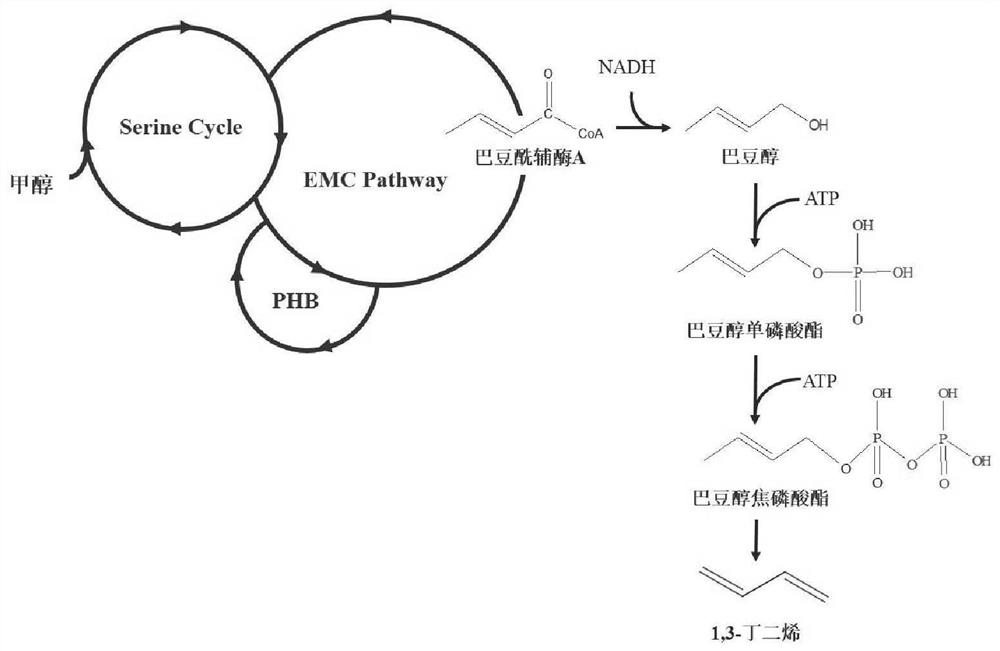

[0054] The butadiene synthesis pathway consists of 4 steps (e.g. figure 2 shown):

[0055] 1) With crotonyl coenzyme A as a precursor, coenzyme A reductase (coenzyme A reductase Far or butyraldehyde dehydrogenase-butanol dehydrogenase BLD-BDH or aldol dehydrogenase ADHE2) of the present invention converts crotonyl coenzyme A Coenzyme A is reduced to crotyl alcohol;

[0056] 2) crotyl alcohol is phosphorylated into crotyl alcohol monophosphate by crotyl alcohol kinase (THK or MK or TK);

[0057] 3) Crotyl alcohol monophosphate kinase IPK catalyzes the phosphorylation of crotyl alcohol monophosphate to generate crotyl alcohol pyrophosphate;

[0058] 4) Butadiene synthase MTS or ISPS catalyzes crotyl alcohol pyrophosphate to generate butadiene.

[0059] (1) For the first step reaction, according to the structural characteristics of the substrate crotonyl-CoA and the mechanism of the enzyme-catalyzed reaction, the present invention screens the bld-bdh from Clostridium saccharo...

Embodiment 2

[0067] Following the experimental operation of Example 1, the construction of a one-pot reaction from crotonyl-CoA to butadiene in vitro.

[0068] Select the enzyme with the highest catalytic efficiency in each step to build a one-pot reaction system, which are FAR (from Marinobactermanganoxydans), THK, IPK and MTS. First, optimize the pH of the four enzyme reactions, and the pH gradient is 6, 6.5, 7, 7.5, 8, 8.5 and 9, it was found that most of the enzymes catalyzed to generate the highest target products at pH 8.0. The temperature of the four enzymatic reactions was optimized with a temperature gradient of: 29.5°C, 32°C, 34.5°C, 37°C, 39.5°C, 42°C and 44.5°C. It was found that most of the enzymes catalyzed the highest target products at 39.5°C.

[0069] Under the conditions of the optimal temperature of 39.5°C and pH of 8.0, the optimal enzyme amount of each enzyme in the one-pot reaction was optimized, and the enzyme amount gradient was 0.25mg / mL, 0.5mg / mL, 1mg / mL and 1.5m...

Embodiment 3

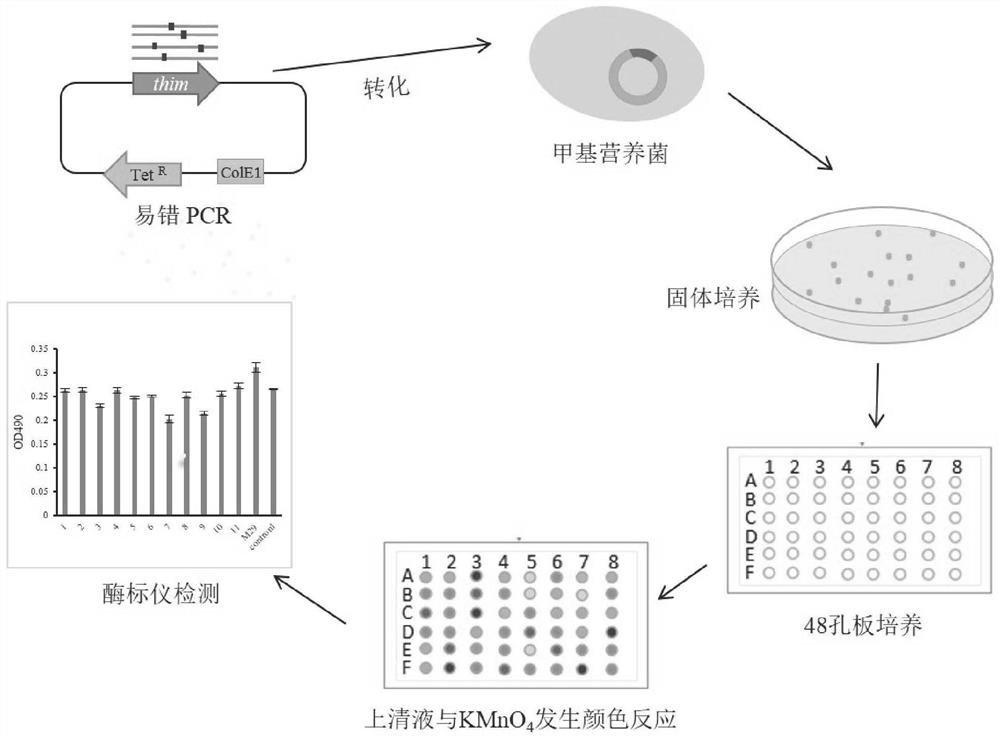

[0073] The four genes far+thim+ipk+mts are expressed in Methylobacterium extorquens AM1, and each two genes are connected by RBS. Construct the target gene fragment of BamHI restriction site+far+RBS+thim+RBS+ipk+RBS+mts+SacI restriction site, and carry out step-by-step digestion on the target gene fragment and pCM80, and combine the target gene and plasmid After the backbone was ligated through restriction sites BamHI and SacI, plasmid pYJ was obtained. Then point-transfer into M. extorquens AM1 to construct strain M. extorquensAM1-pYJ. Inoculate strain AM1-pYJ to prepare seed liquid, and then carry out vial culture. The specific vial culture condition is to use 10mL Hypho medium with 10ug / mL tetracycline in a 50mL anaerobic vial at 30°C, 200rpm shaker, and seal it away from light. Cultivate for 70h. The standard of inoculum volume is OD 600 =0.8 seed liquid inoculation 1mL, the thalline growth status of above-mentioned culture uses absorbance OD 600 To characterize; butad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com