Preparation method of capacitor material having 3D hollow structure and application thereof

A hollow structure, capacitor technology, applied in hybrid capacitor electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as complex process, achieve good repeatability, superior electrochemical properties, and preparation process Simple and Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, cobalt chloride, nickel chloride, ammonium fluoride, sodium sulfide, urea and silk are used as experimental raw materials, and the specific preparation process is as follows:

[0021] (1) Take 50ml of sodium carbonate solution with a mass fraction of 5% and place it in a 100ml beaker, immerse the silkworm cocoons in the solution, heat it to 100°C by means of oil bath heating and keep it warm for 30min, then use the obtained silk to remove Wash with deionized water several times, and dry at 60°C for 12 hours;

[0022] (2) Take by weighing reagent 1mmol nickel chloride (0.2377g), 2mmol cobalt chloride (0.4759g), 10mmol urea (0.6006g), 10mmol ammonium fluoride (0.3700g), be dissolved in the beaker of 50mL deionized water, In the process of adding the reagent, the solution needs to be stirred continuously until a clear pink solution is formed; then the solution and the silk obtained in step (1) are placed in a 100mL stainless steel autoclave lined with p...

Embodiment 2

[0026] Concrete preparation steps (1), (2), (3) of the present embodiment are the same as embodiment 1, and step (4) is:

[0027] (4) Put the 3D hollow structural material obtained in step (3) in a porcelain boat and place it in a tube furnace, heat it to 300°C in an air atmosphere and keep it warm for 2 hours to obtain the oxidized 3D hollow structural material, It is a capacitor material with a 3D hollow structure.

Embodiment 3

[0029]Concrete preparation steps (1), (2), (3) of the present embodiment are the same as embodiment 1, and step (4) is:

[0030] (4) Put the 3D hollow structural material obtained in step (3) in a porcelain boat and place it in a tube furnace, heat it to 500°C in an air atmosphere and keep it warm for 2 hours to obtain the oxidized 3D hollow structural material, It is a capacitor material with a 3D hollow structure.

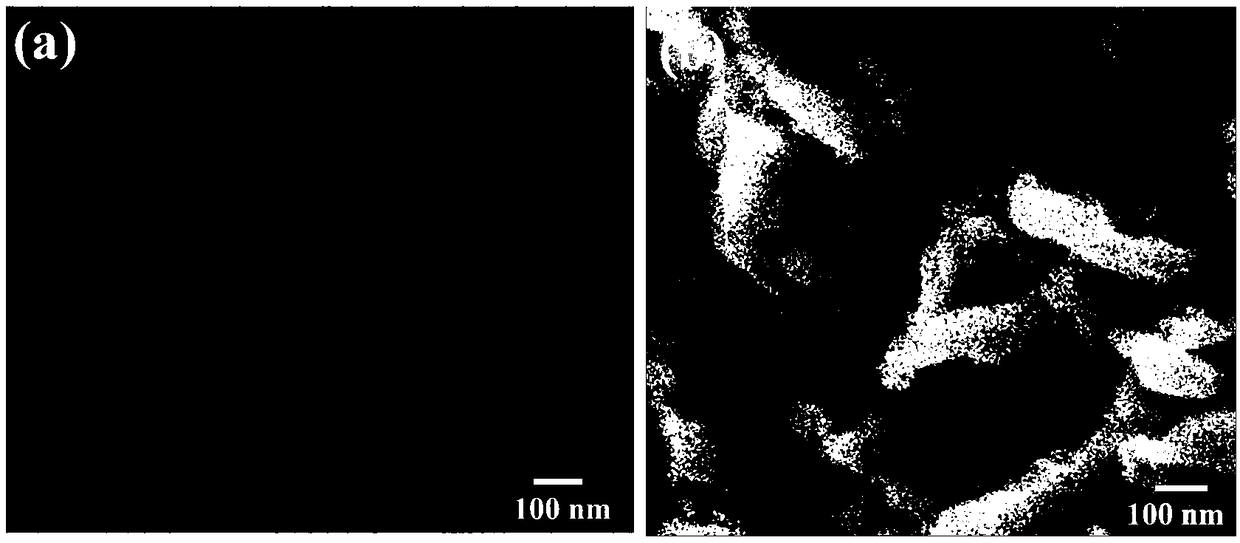

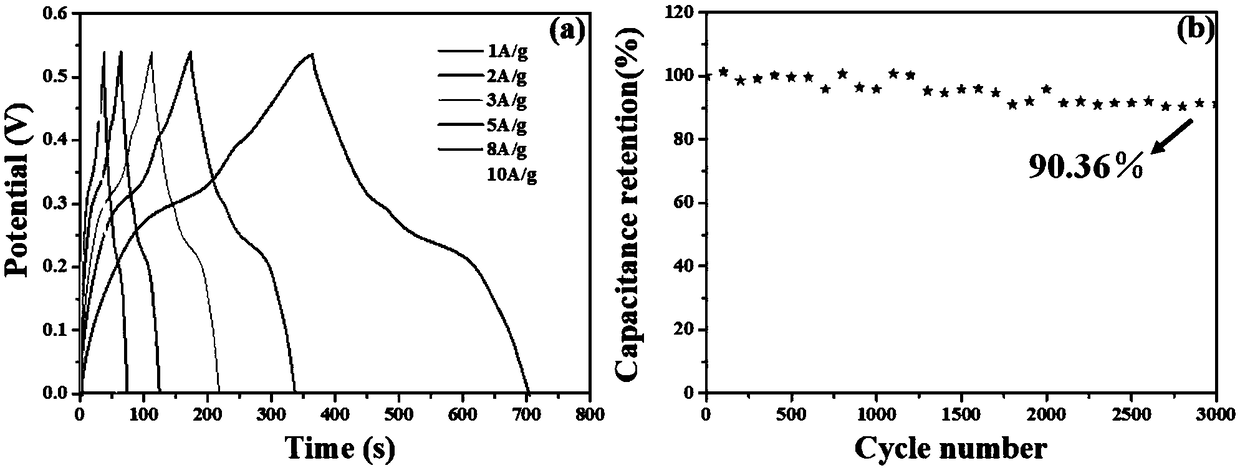

[0031] Through the characterization of the scanning electron microscope, the thorny NiCo that grows on the surface of the silk is prepared in Example 1. 2 S 4 The nanowire structure remained intact and formed a hollow structure with a diameter of 8.23nm, and no "collapse" phenomenon was observed, such as figure 1 . And changing the oxidation and calcination treatment conditions, mainly the temperature, has a great impact on the material NiCo 2 S 4 The morphology and structure of the nanowires have a significant impact, such as figure 2 , at lower or higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com