Fodder for lowering exhaust of methane of intestinal tract of cow and preparing method of fodder

A feed and intestinal technology, which is applied in the field of feed and its preparation for reducing methane emission in cattle intestines, can solve the problems of low feed digestibility, increased fecal methane production, affecting animal production performance, etc., so as to improve meat quality and improve animal performance. Effects of daily weight gain and inhibition of methane production in ruminants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

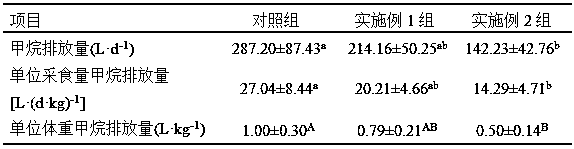

Embodiment 1

[0025] A method for preparing feed for reducing methane emissions from the intestinal tract of cattle:

[0026] (1) Weigh raw materials by weight: 45 parts of whole corn silage, 4 parts of alfalfa hay, 17.2 parts of corn, 6.4 parts of bran, 13 parts of soybean meal, 2 parts of peanut cake, 1.5 parts of germ meal, 2.5 parts of DDGS feed, 0.4 part of premix, 0.4 part of table salt, 0.6 part of sodium bicarbonate, 0.4 part of stone powder, 0.6 part of calcium bicarbonate and 0.22 part of aloe vera powder;

[0027] (2) Put crushed corn, bran, soybean meal, peanut cake, germ meal, DDGS feed and premix and aloe vera powder into the mixer to make a concentrated feed;

[0028] (3) Add coarse alfalfa hay and whole plant corn silage to the concentrated feed in sequence, then add water with a mass of 50% of the raw material, and finally add 0.4 parts of salt, 0.6 parts of sodium bicarbonate, 0.4 parts of stone powder and 0.6 parts of calcium bicarbonate, Stir for 7 minutes to complete t...

Embodiment 2

[0031] A method for preparing feed for reducing methane emissions from the intestinal tract of cattle:

[0032] (1) Weigh raw materials by weight: 52 parts of whole corn silage, 8 parts of alfalfa hay, 20 parts of corn, 10.8 parts of bran, 12.4 parts of soybean meal, 4 parts of peanut cake, 3 parts of germ meal, 5 parts of DDGS feed, 0.4 part of premix, 0.4 part of table salt, 0.6 part of sodium bicarbonate, 0.4 part of stone powder, 0.6 part of calcium bicarbonate and 0.32 part of aloe vera powder;

[0033] (2) Put crushed corn, bran, soybean meal, peanut cake, germ meal, DDGS feed and premix and aloe vera powder into the mixer to make a concentrated feed;

[0034] (3) Add coarse alfalfa hay and whole plant corn silage to the concentrated feed in sequence, then add water with a mass of 55% of the raw material, and finally add 0.4 part of salt, 0.6 part of sodium bicarbonate, 0.4 part of stone powder and 0.6 part of calcium bicarbonate, Stir for 8 minutes to complete the prepar...

Embodiment 3

[0037] A method for preparing feed for reducing methane emissions from the intestinal tract of cattle:

[0038] (1) Weigh raw materials by weight: 38 parts of whole corn silage, 0.1 part of alfalfa hay, 14.4 parts of corn, 2 parts of bran, 3.6 parts of soybean meal, 0.1 part of peanut cake, 0.1 part of germ meal, 0.1 part of DDGS feed, 0.4 part of premix, 0.4 part of table salt, 0.6 part of sodium bicarbonate, 0.4 part of stone powder, 0.6 part of calcium bicarbonate and 0.12 part of aloe vera powder;

[0039] (2) Put crushed corn, bran, soybean meal, peanut cake, germ meal, DDGS feed and premix and aloe vera powder into the mixer to make a concentrated feed;

[0040] (3) Add coarse alfalfa hay and whole plant corn silage to the concentrated feed in sequence, then add water with a mass of 45% of the raw material, and finally add 0.4 parts of salt, 0.6 parts of sodium bicarbonate, 0.4 parts of stone powder and 0.6 parts of calcium bicarbonate, Stir for 5 minutes to complete th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com