Graphene titanium dioxide composite nano material and preparation method thereof

A technology of composite nanomaterials and titanium dioxide, applied in the field of nanomaterials, can solve problems such as difficulty in applying large-scale production, and achieve the effects of good photocatalytic performance, high catalytic degradation efficiency and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

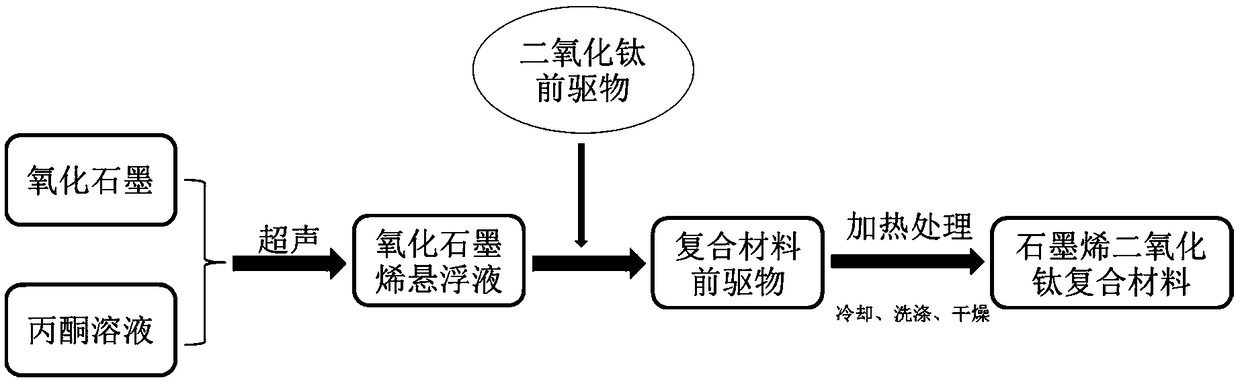

[0032] This embodiment proposes a method for a graphene-titanium dioxide composite nanomaterial, and the preparation method of the nanocomposite comprises the following steps:

[0033] 1. Weigh a certain amount of dried graphite oxide and dissolve it in an acetone solution, and disperse it ultrasonically for 0.5-1 h to prepare a graphene oxide suspension A with a concentration of 0.001-0.01 mol / L.

[0034] In the process of preparing the graphene oxide suspension A, the improved Hummers method is used to synthesize graphite oxide. The Hummers method is a method commonly used by those skilled in the art to prepare graphite oxide, and will not be described here.

[0035] 2. Add a certain amount of titanate compounds into the alcohol solution, and stir at room temperature for 6-8 hours to prepare titanium dioxide precursor solution B.

[0036] In the process of preparing the titanium dioxide precursor solution B, at least one titanate compound selected from tetrabutyl titanate an...

Embodiment 1

[0045] like figure 1 As shown, embodiment 1 proposes a kind of preparation method of graphene-titanium dioxide composite nanomaterial, specifically comprises the following steps:

[0046] 1. Weigh a certain amount of dry graphite oxide synthesized by the Hummers method, dissolve it in an acetone solution, and disperse it ultrasonically for 0.5-1 h to prepare a graphene oxide suspension A with a concentration of 0.002 mol / L.

[0047] 2. Add a certain amount of tetrabutyl titanate with a mass fraction of 97% into the ethylene glycol solution, the volume ratio of tetrabutyl titanate to ethylene glycol is 0.08:10, stir at room temperature for 7 hours, and prepare titanium dioxide Precursor Solution B.

[0048] 3. Add 3ml of titanium dioxide precursor solution B to the graphene oxide suspension A, mix well, let stand for several hours, and then centrifuge the precipitate to obtain the precipitate.

[0049] 4. After adding 15ml of deionized water to the precipitate, transfer it to t...

Embodiment 2

[0054] Embodiment 2 proposes a kind of preparation method of graphene titanium dioxide composite nano material, specifically comprises the following steps:

[0055] 1. Weigh a certain amount of dry graphite oxide synthesized by the Hummers method, dissolve it in an acetone solution, and disperse it ultrasonically for 1 hour to prepare a graphene oxide suspension A with a concentration of 0.005 mol / L.

[0056] 2. Add a certain amount of tetrabutyl titanate with a mass fraction of 97% to the ethylene glycol solution, the volume ratio of tetrabutyl titanate to ethylene glycol is 0.13:10, and stir at room temperature for 6 hours to prepare titanium dioxide Precursor Solution B.

[0057] 3. Add 6ml of titanium dioxide precursor solution B to graphene oxide suspension A, mix well, let stand for several hours, and then centrifuge the precipitate to obtain the precipitate.

[0058] 4. After adding 15ml of deionized water to the precipitate, transfer it to the reaction kettle and seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com