A three-dimensional high-density metal nanoparticle/graphene porous composite material and its preparation method and application

A technology of porous composite materials and metal nanoparticles, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as low theoretical specific capacity and unsatisfactory energy density, and achieve high specific surface area , Improve space utilization and avoid reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation:

[0044] (1) First, the graphene oxide and KOH solids were mixed and stirred for 4h with a mass ratio of 1:3 (stirring rate was 500rpm), and then placed at room temperature for 20h;

[0045] (2) Dry the above-mentioned product at 65°C for 24h under air conditions, then place it in a tube furnace for 1h at 800°C, and after natural cooling, wash and dry it with 0.1mol / L dilute hydrochloric acid and deionized water After processing, porous graphene is obtained;

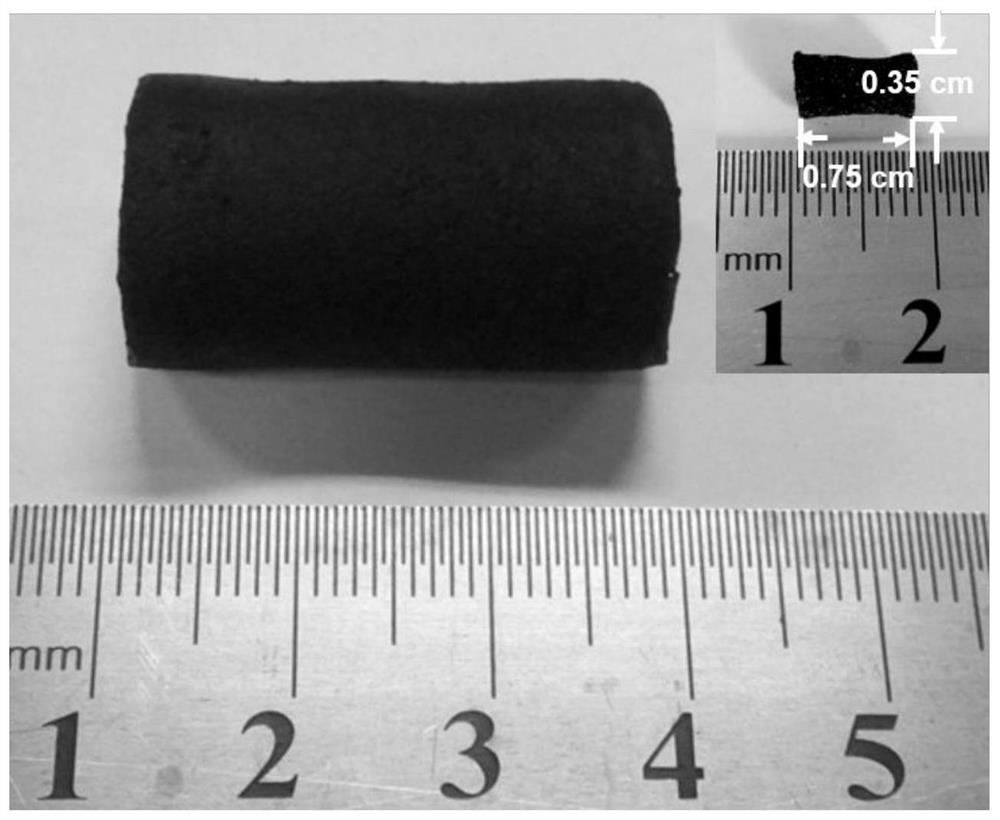

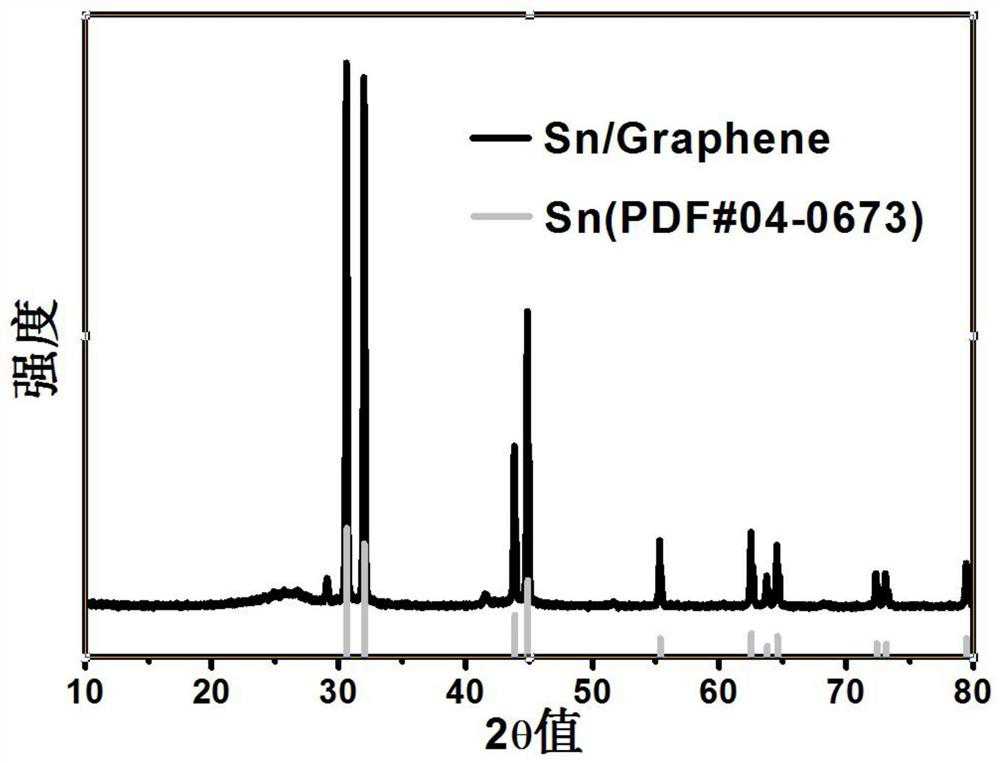

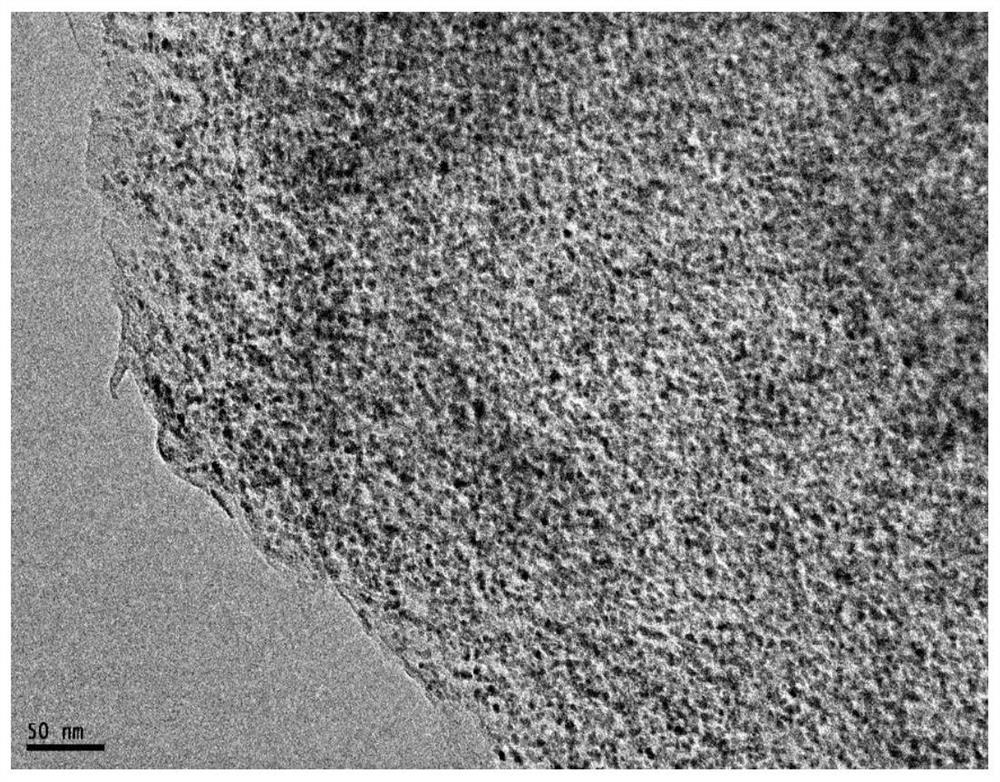

[0046] (3) 80 mg of the porous graphene powder sample prepared above was added to 448 mL of ethanol solution, and ultrasonicated in an ultrasonic disperser for 20 min. Then, 0.4mmol of SnCl 4 Slowly added to the above ultrasonic solution under the condition of magnetic stirring. Then, measure 32 mL of deionized water, slowly drop it into the above ultrasonic solution under magnetic stirring, and magnetically stir for 30 min. Then, put the solution in a hydrothermal kettle and heat it in a vacuu...

Embodiment 2

[0052] 1. Preparation:

[0053] (1) First, the graphene oxide and KOH solids were mixed and stirred for 8h (stirring rate was 500rpm) at a mass ratio of 1:3, and then placed at room temperature for 24h;

[0054] (2) Dry the above-mentioned product at 70°C for 24h under air conditions, then place it in a tube furnace for 3h at 700°C, and after natural cooling, wash and dry it with 0.1mol / L dilute hydrochloric acid and deionized water After processing, porous graphene is obtained;

[0055] (3) Add 100 mg of the porous graphene powder sample prepared above into 560 mL of methanol solution, and ultrasonicate for 15 min in an ultrasonic disperser. Then, 0.8mmol of Sn(NO 3 ) 4 Slowly added to the above ultrasonic solution under the condition of magnetic stirring. Then, measure 40 mL of deionized water, slowly drop it into the above ultrasonic solution under magnetic stirring, and magnetically stir for 30 min. Then, put the solution in a hydrothermal kettle and heat it in a vacu...

Embodiment 3

[0061] 1. Preparation:

[0062] (1) First, the graphene oxide and KOH solids were mixed and stirred for 6h (stirring rate was 500rpm) at a mass ratio of 1:3, and then placed at room temperature for 12h;

[0063] (2) Dry the above-mentioned product at 80°C for 24h under air conditions, then place it in a tube furnace for 0.5h at 1000°C, and after natural cooling, wash and dry it with 0.1mol / L dilute hydrochloric acid and deionized water After dry processing, porous graphene is obtained;

[0064] (3) 100 mg of the porous graphene powder sample prepared above was added to 560 mL of ethylene glycol solution, and ultrasonicated in an ultrasonic disperser for 20 min. Then, 0.4mmol of GeCl 4 Slowly added to the above ultrasonic solution under the condition of magnetic stirring. Then, measure 40 mL of deionized water, slowly drop it into the above ultrasonic solution under magnetic stirring, and magnetically stir for 30 min. Then, put the solution in a hydrothermal kettle, and hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com