A kind of negative electrode material for potassium ion battery and its preparation method and electrolyte

A negative electrode material, potassium ion technology, applied in the field of electrochemistry, can solve problems such as specific capacity to be improved, poor cycle performance, large volume expansion, etc., to achieve the effect of improving electrochemical performance, excellent rate performance, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

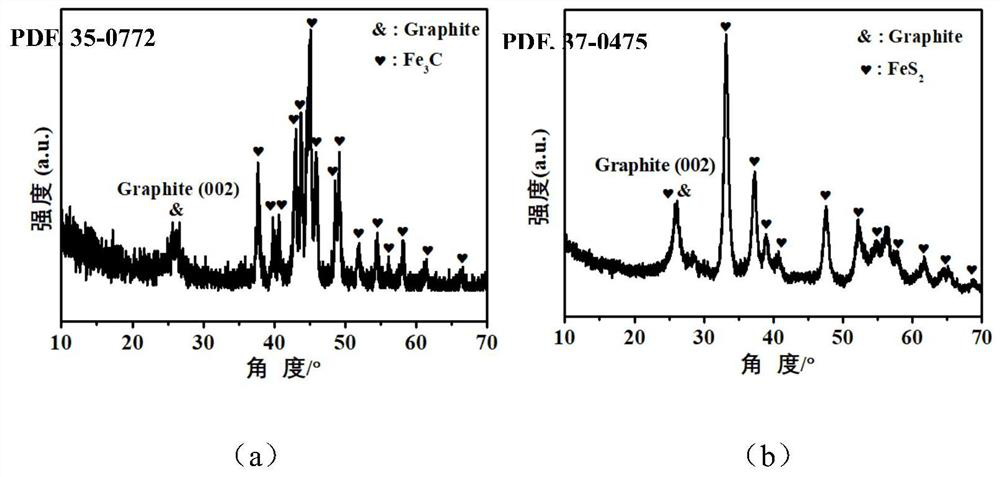

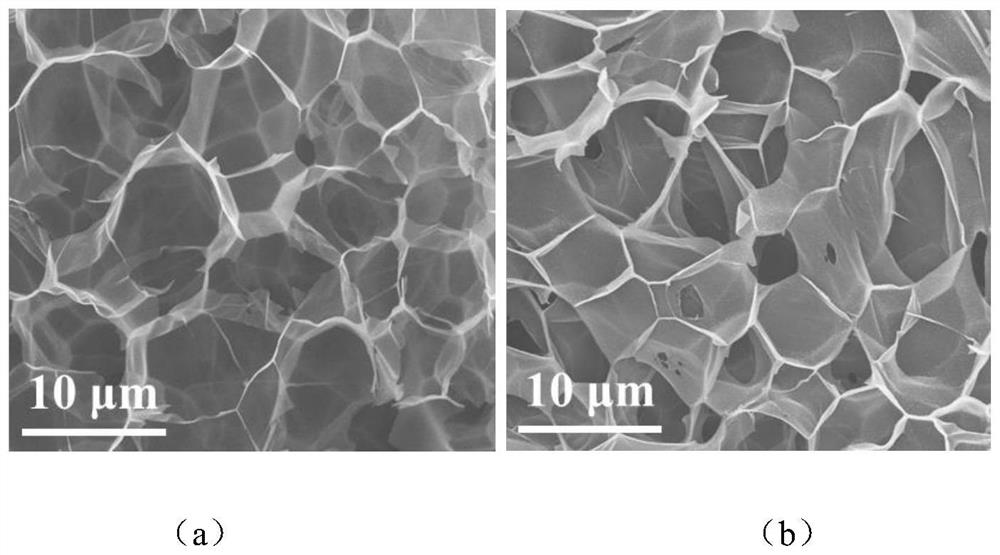

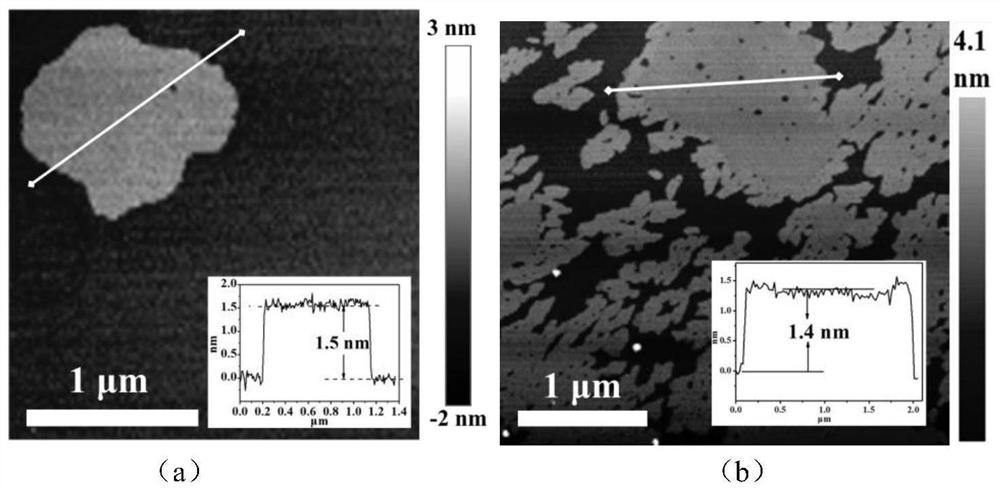

[0028] Weigh polyvinylpyrrolidone powder and ferric nitrate nonahydrate according to the mass ratio of 1:1.5, dissolve ferric nitrate nonahydrate and polyvinylpyrrolidone nonahydrate respectively in deionized water to make a mixed solution and stir it ultrasonically for 10 minutes, then place the mixed solution in air-dried Keep warm at 80°C in the box until it is completely dry, then grind the dried product into powder and transfer the powder to a crucible, which is placed in a tube furnace under N 2 Heated to 700°C at a heating rate of 5°C / min in the atmosphere, and held for 1 hour. After the tube furnace cooled, the black foamy product was collected to obtain a three-dimensional porous nitrogen-doped graphene composite material decorated with iron carbide nanoparticles. Take an appropriate amount of three-dimensional porous nitrogen-doped graphene composite powder modified by iron carbide nanoparticles in a crucible, and then place the crucible at the downstream position of ...

Embodiment 2

[0031] Mix the three-dimensional porous nitrogen-doped graphene composite material modified with iron carbide nanoparticles, the conductive agent Ketjen black and the binder polyvinylidene fluoride (PVDF) at a mass ratio of 7:2:1, grind evenly and add an appropriate amount of N- Methylpyrrolidone (NMP) is made into a slurry, which is uniformly coated on the copper foil. After vacuum drying at 100°C for 10 h, it was cut into electrode sheets with a diameter of 10 mm by a microtome for use. With metal potassium sheet as counter electrode, glass fiber as diaphragm, 1mol / L KPF 6 / EC / DEC is the electrolyte, and it is assembled into a CR2032 button cell in an argon-protected glove box. After the battery is assembled, let it stand for 12 hours, and use the LAND CT2001A battery test system to conduct a constant current charge and discharge test with a test voltage of 0.01-2.5V.

[0032] Figure 5 It is the charge-discharge curve of the prepared three-dimensional porous nitrogen-dop...

Embodiment 3

[0034] Mix the three-dimensional porous nitrogen-doped graphene composite material modified with iron carbide nanoparticles, the conductive agent Ketjen black and the binder polyvinylidene fluoride (PVDF) at a mass ratio of 6:3:1, grind evenly and add an appropriate amount of N- Methylpyrrolidone (NMP) is made into a slurry, which is uniformly coated on the copper foil. After vacuum drying at 100°C for 10 h, it was cut into electrode sheets with a diameter of 10 mm by a microtome for use. With metal potassium sheet as counter electrode, glass fiber as diaphragm, 1mol / L KPF 6 / EC / DEC is the electrolyte, and it is assembled into a CR2032 button cell in an argon-protected glove box. After the battery is assembled, let it stand for 12 hours, and use the LAND CT2001A battery test system to conduct a constant current charge and discharge test with a test voltage of 0.01-2.5V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com