Waste wood and plastic coated recycled aggregate bituminous concrete and preparation method and application thereof

A technology of asphalt concrete and recycled aggregates, applied in roads, road repairs, construction, etc., can solve problems such as insufficient bonding strength, no significant reduction in water strength, and underutilization, etc., to reduce costs and process energy consumption , huge economic and environmental benefits, avoiding the effect of high crushing index value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

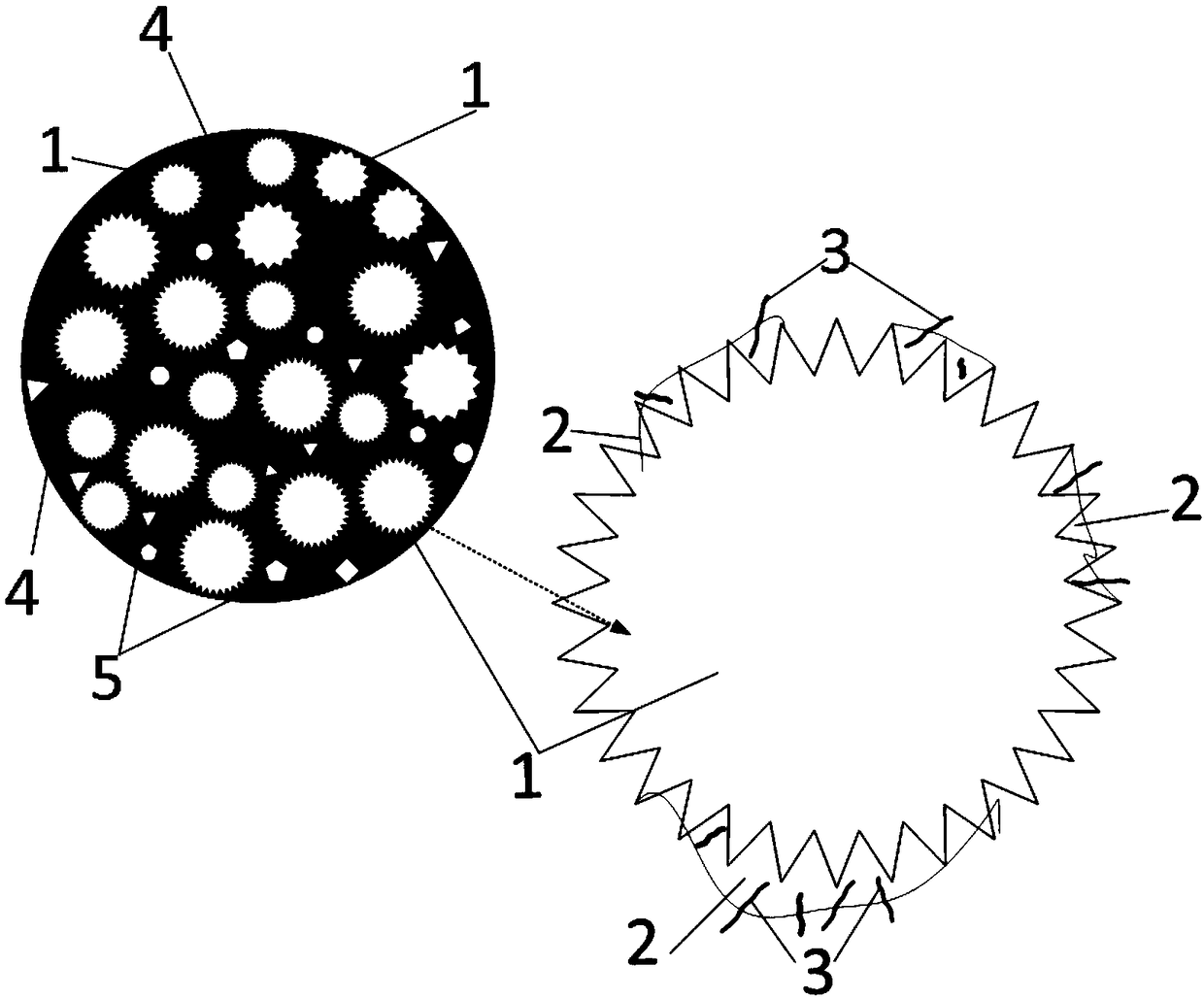

Image

Examples

Embodiment 1

[0024] The specific steps of the waste wood-plastic coated recycled aggregate asphalt concrete preparation process are as follows:

[0025] S1: Firstly, waste ethylene-vinyl acetate copolymer-based agricultural plastic greenhouse film and reinforced concrete-based building demolition concrete were respectively used in "Recycling Method for Recycling Waste Plastics After Industry" and "A Method for Using Waste Concrete to Prepare High-quality Recycled Fine Aggregate" "Method" and other technologies well known in the art for collection, classification, processing, crushing and granulation to produce recycled plastic particles with a particle size of 10-30mm, and recycled plastic particles with a nominal particle size between 2.36mm≤particle size≤26.5mm Materials, nominal maximum particle size ≤ 0.6mm regenerated mineral powder; waste wood powder is the remaining corner waste from wood processing using a wood powder crusher through crushing, screening, drying, powder making and ot...

Embodiment 2

[0032] The preparation process and structure of the waste wood-plastic-coated recycled aggregate asphalt concrete are the same as in Example 1. The difference is: the waste plastic used is polyvinyl chloride plastic, and the corresponding viscous temperature is 160°C; the recycled aggregates all replace ordinary aggregates; the application site is changed to a municipal park square.

[0033] The rheological viscosity coefficient of viscous fluid polyvinyl chloride measured by rotational viscometer is 6.7×10 3 mPa·s; The specific surface area of the recycled aggregate measured by the vapor adsorption method is 2.79m 2 / kg; Combined with the surface tension tester, the surface coverage rate of the corresponding waste wood powder / waste polyvinyl chloride wood-plastic thin layer partially coated recycled aggregate is 33.5%.

[0034] The stability, flow value, and residual stability of asphalt concrete samples coated with waste wood-plastic thin layer coated recycled aggregates ...

Embodiment 3

[0036] The preparation process and structure of the waste wood-plastic-coated recycled aggregate asphalt concrete are the same as in Example 1. The difference is: the waste plastics used are high-density polyethylene plastics, and the recycled aggregates are recycled traffic aggregates and recycled traffic mineral powders processed from waste traffic waste generated by intermediate traffic roads; the application site is changed to a basement parking lot .

[0037] The rheological viscosity coefficient of viscous flow high-density polyethylene measured by rotational viscometer is 2.2×10 3mPa s; The specific surface area of the recycled traffic aggregate measured by the vapor adsorption method is 2.34m 2 / kg; Combined with the surface tension tester, the surface coverage rate of the corresponding waste wood powder / high-density polyethylene thin layer partially coated recycled traffic aggregate is 31.5%.

[0038] The stability, flow value, and residual stability of asphalt co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com