Geopolymeric concrete and preparation method thereof

A geopolymer and concrete technology, applied in the field of concrete, can solve the problem of high preparation cost and achieve the effect of reducing and saving the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

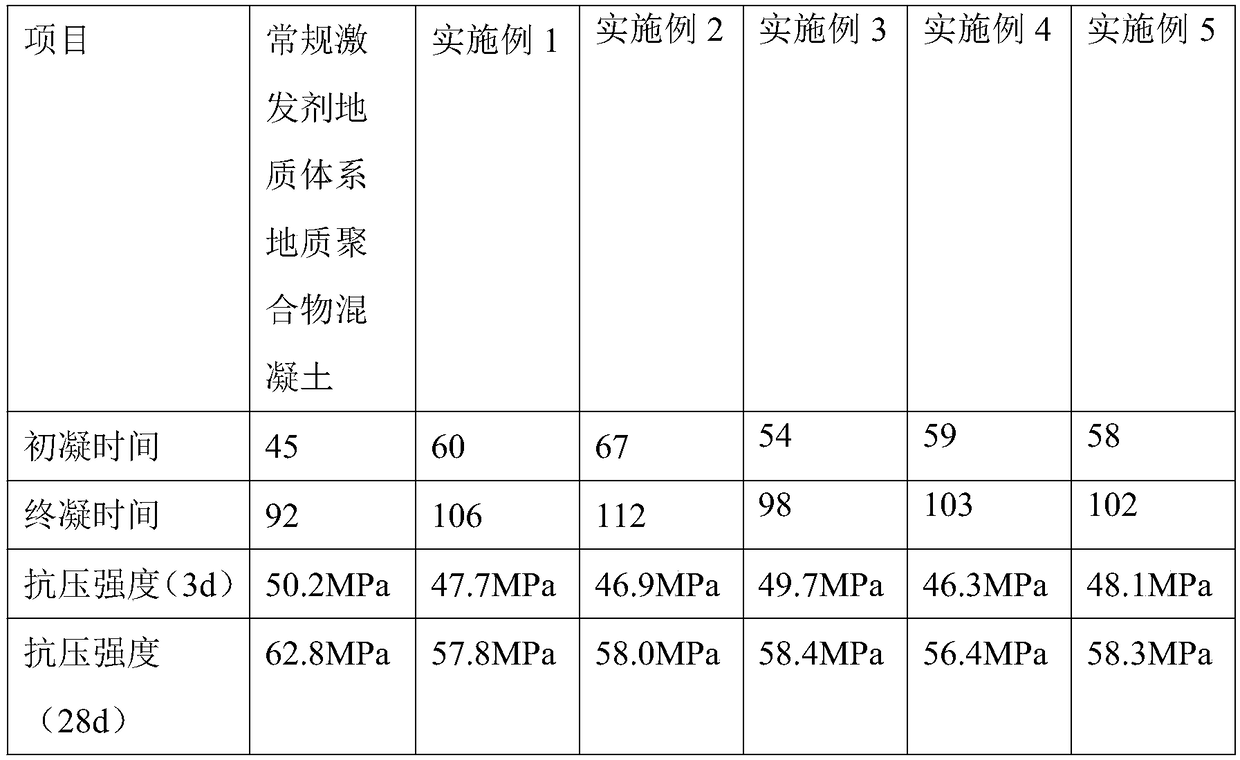

Examples

Embodiment 1

[0030] A geopolymer concrete, prepared by mixing and stirring the following raw materials: slag (S95 grade slag, specific surface area 410m 2 / kg, SiO 2 with Al 2 o 3 The mass ratio is 2.8): 300 parts, fly ash (Class I fly ash, SiO 2 with Al 2 o 3 The mass ratio is 2.4): 60 parts, silica fume (SiO 2 content 97.6%): 40 parts, composite activator: 230 parts, sodium lignosulfonate (water reducer): 2 parts, sodium pyrophosphate (retarder): 1 part, fine aggregate (quartz sand, medium sand , fineness modulus 2.5)): 680 parts, coarse aggregate (5-31mm continuously graded stone): 1230 parts, fiber (basalt fiber, length 25mm, aspect ratio 600): 4.8 parts, calculated in parts by weight .

[0031] Among them, the composite activator is prepared from the following raw materials under the heating condition of 65°C: instant sodium silicate (powder, modulus 2.9): 32 parts, sodium hydroxide (industrial grade, tablet) 4 parts, high aluminum-containing alkali Sexual waste liquid (sodium...

Embodiment 2

[0036]A geopolymer concrete, prepared by mixing and stirring the following raw materials: slag (S95 grade slag, specific surface area 410m 2 / kg, SiO 2 with Al 2 o 3 The mass ratio is 2.8): 290 parts, fly ash (Class I fly ash, SiO 2 with Al 2 o 3 The mass ratio is 2.4): 60 parts, silica fume (SiO 2 content 97.6%): 40 parts, composite activator: 230 parts, sodium lignosulfonate (water reducer): 2 parts, sodium pyrophosphate (retarder): 1 part, fine aggregate (quartz sand, medium sand , fineness modulus 2.5)): 680 parts, coarse aggregate (5-31mm continuously graded stone): 1230 parts, fiber (basalt fiber, length 25mm, aspect ratio 600): 4.8 parts, calculated in parts by weight .

[0037] Among them, the composite activator is prepared from the following raw materials under heating conditions (65°C): instant sodium silicate (powder, modulus 2.9): 32 parts, sodium hydroxide (industrial grade, tablet) 4 parts, high aluminum content Alkaline waste liquid (sodium hydroxide co...

Embodiment 3

[0042] A geopolymer concrete, prepared by mixing and stirring the following raw materials: slag (S95 grade slag, specific surface area 410m 2 / kg, SiO 2 with Al 2 o 3 The mass ratio is 2.8): 310 parts, fly ash (Class I fly ash, SiO 2 with Al 2 o 3 The mass ratio is 2.4): 55 parts, silica fume (SiO 2 content 97.6%): 38 parts, composite activator: 230 parts, sodium lignosulfonate (water reducing agent): 2 parts, sodium pyrophosphate (retarder): 1 part, fine aggregate (quartz sand, medium sand , fineness modulus 2.5)): 680 parts, coarse aggregate (5-31mm continuously graded stone): 1230 parts, fiber (basalt fiber, length 25mm, aspect ratio 600): 4.8 parts, calculated in parts by weight .

[0043] Among them, the composite activator is prepared from the following raw materials under heating conditions (65°C): instant sodium silicate (powder, modulus 2.9): 32 parts, sodium hydroxide (industrial grade, tablet) 4 parts, high aluminum content Alkaline waste liquid (sodium hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com