High-heat-conductivity crosslinkable resin composition as well as prepreg and thermosetting copper-clad plate prepared thereby

A cross-linked resin and prepreg technology, applied in the field of communication materials, can solve the problems of high-speed, high-frequency, lossless and large-capacity information transmission, limited addition of thermal conductive fillers, and limited improvement of substrate thermal conductivity, etc., to achieve good industrialization The production basis, the uniformity of various properties, and the effect of suitable viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

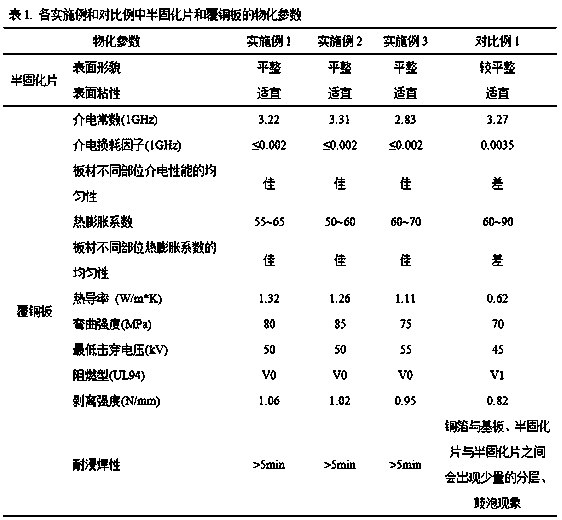

Embodiment 1

[0017] Take 70 parts of polybutadiene (Craigville Ricon130), 30 parts of polybutadiene-maleic anhydride copolymer (Craigville Ricon130MA8), 40 parts of BN (particle size 5 μm), 5 parts of SiO 2 (Xinyi Hongrun), 35 parts of decabromodiphenylethane (Shandong Haiwang Chemical) and 1 part of dibenzoyl peroxide (Qinfeng Chemical), 20 o C, stirred and mixed in a ball mill for 120 hours to obtain a uniform high thermal conductivity polydiene composition; the composition was scraped on a clean stainless steel plate to form a film with a thickness of about 0.81 mm, and after baking at 65 ° C for 25 minutes, Continue to bake at 120°C for 60 minutes. After it naturally drops to room temperature, peel off the film from the stainless steel sheet to obtain a semi-cured dielectric sheet; take 1 sheet of the semi-cured dielectric sheet and 2 pieces of loz copper foil, and heat it under a pressure of 130 ~150kg / cm 2 , and laminated for 8 hours at a temperature of 320° C. to prepare a thermose...

Embodiment 2

[0019] Take 65 parts of polybutadiene (Kray Willy Ricon130), 35 parts of polybutadiene-maleic anhydride copolymer (Kray Willy Ricon130MA8), 15 parts of BN (particle size 5 μm), 20 parts of SiC (particle size 6μm), 30 parts of flame retardant magnesium hydroxide (USA Albemarle MAGNIFIN H-5), 20 parts of decabromodiphenylethane (Shandong Haiwang Chemical) and 0.9 parts of dibenzoyl peroxide (Qinfeng Chemical), 20 o C, after stirring and mixing in a ball mill for 120h, a uniform high thermal conductivity polydiene composition was obtained; the molding temperature was set at 25 o C. Molding pressure is 30kg / cm 2 1. The molding time is 10 minutes, and the composition is made into a film with a thickness of about 0.81mm. After baking at 65°C for 25 minutes, continue to bake at 120°C for 60 minutes. Peel off the stainless steel sheet to obtain a semi-cured dielectric sheet; take 1 sheet of the semi-cured dielectric sheet and 2 pieces of loz copper foil, and press it under a pressure...

Embodiment 3

[0021] Take 65 parts of polybutadiene (Kray Willy Ricon130), 35 parts of polybutadiene-maleic anhydride copolymer (Kray Willy Ricon130MA8), 35 parts of BN (particle size 5 μm), 45 parts of polytetrafluoroethylene Pre-sintered material (Shandong Dongyue), 28 parts of decabromodiphenylethane (Shandong Haiwang Chemical) and 0.9 parts of dibenzoyl peroxide (Qinfeng Chemical), 20 o C, after stirring and mixing in a ball mill for 120 hours, a uniform high thermal conductivity polydiene composition was obtained; the composition was scraped into a film with a thickness of about 0.81 mm on a clean glass plate, and after baking at 65 ° C for 25 minutes, Continue to bake at 120°C for 60 minutes, and after it naturally drops to room temperature, peel off the film from the glass sheet to obtain a semi-cured dielectric sheet; take 1 sheet of the semi-cured dielectric sheet and 2 sheets of loz copper foil, and heat it under a pressure of 140 ~155kg / cm 2 , and laminated for 8 hours at a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com