Water-based rubber paint, and preparation method thereof

A rubber coating, water-based technology, applied in natural rubber coatings, antifouling/underwater coatings, fire-retardant coatings, etc., can solve the problems of poor high temperature and high humidity resistance, poor impact and wear resistance, poor aging resistance, etc. Good high humidity, lower production cost, good effect of UV protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

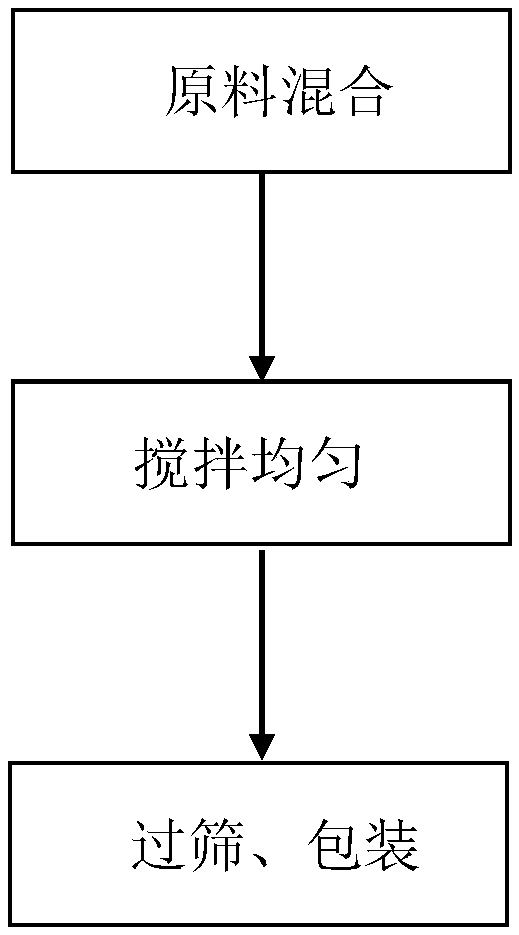

Image

Examples

Embodiment 1

[0030] 1. Preparation of water-based rubber emulsion:

[0031] Pass the natural rubber powder through a 40-mesh sieve, and prepare each raw material component according to the mass percentage, wherein natural rubber: 30%, dispersant BYK-2155: 2%, emulsifier is Japan Emulsifier Co., Ltd. Newcol-293: 3%, Distilled water: 65%, speed 1000 rpm, high-speed dispersion and emulsification for 8 hours, after dispersion and emulsification evenly, pass through a 40-mesh filter to make water-based rubber emulsion A.

[0032] 2. Preparation of water-based rubber coating:

[0033] Prepare the following components according to mass percentage, distilled water: 10%, water-based rubber emulsion A: 65%, water-based acrylic emulsion: 20%, carbon black: 3%, dispersant BYK-2155: 1%, defoamer BYK-011 : 1%, after mixing the above-mentioned raw materials, the rotating speed is 50 rev / min, after stirring for 2 hours, pass through a 40-mesh sieve, and seal the package.

[0034] 3. Experimental detecti...

Embodiment 2

[0036] 1. Preparation of water-based rubber emulsion:

[0037] Pass the butadiene rubber powder through a 40-mesh sieve, and prepare the components according to the mass percentage, butadiene rubber: 44%, dispersant BYK-2155: 15%, emulsifier: Japan Emulsifier Co., Ltd. Newcol-297: 1%, Deionized water: 40%, disperse and emulsify at high speed for 5 hours at a speed of 3000 rpm, disperse and emulsify evenly, and pass through a 40-mesh filter to make water-based rubber emulsion B.

[0038] 2. Preparation of water-based rubber coating:

[0039] Prepare the following raw material components according to mass percentage, deionized water: 10%, water-based rubber emulsion B: 45%, water-based polyurethane emulsion: 15%, titanium dioxide: 14%, stone powder: 4%; stone material: 10%, dispersant BYK-2155: 1%, antifoaming agent BYK-011: 1%, stirred for 5 hours at 200 rpm, passed through a 40-mesh sieve after stirring, and packed.

[0040] 3. Experimental detection: apply the water-based r...

Embodiment 3

[0042] 1. Preparation of water-based rubber emulsion:

[0043] Pass natural rubber, isoprene rubber, butadiene rubber powder through a 40-mesh sieve, and prepare various raw material components according to mass percentage, natural rubber 20%, isoprene rubber 30%, butadiene rubber: 10%, dispersant BYK-9076 : 2%, emulsifier: Japan Emulsifier Co., Ltd. Newcol-291-M: 3%, Newcol-297: 5%, deionized water: 30%, high-speed dispersion, emulsification for 1 hour, rotating speed 8000 rpm, dispersion, After the emulsification is uniform, pass through a 40-mesh filter to make water-based rubber emulsion C.

[0044] 2. Preparation of water-based rubber coating:

[0045]Prepare the following raw material components according to mass percentage, distilled water: 5%, water-based rubber emulsion C: 80%, water-based fluorocarbon resin emulsion 13%, leveling agent BYK-333: 1%, defoamer BYK-024: 1% , stirred for 2 hours at a speed of 120 rpm, passed through a 40-mesh sieve after stirring, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com