Reactive type polyurethane hot melt adhesive for flexible packaging lithium ion battery edgefold

A polyurethane hot-melt adhesive and lithium-ion battery technology, which is applied in the field of polyurethane hot-melt adhesives, can solve problems such as insufficient adhesion between the side and the battery core body, weak adhesion between the side tape and the battery core body, and inconsistent adhesive tape positions , to achieve the effect of improving dimensional stability and safety performance, moderate opening time, and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

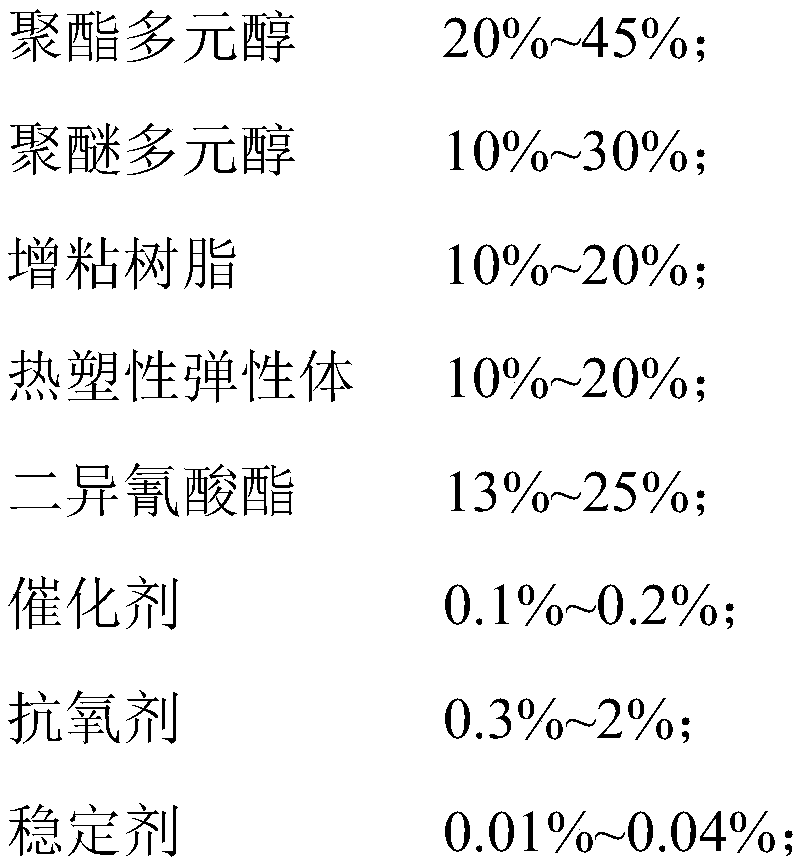

[0030] This embodiment provides a reactive polyurethane hot-melt adhesive for folding lithium-ion batteries in flexible packaging. In terms of mass percentage, the hot-melt adhesive includes the following components:

[0031]

[0032] The preparation steps of this hot melt adhesive are as follows:

[0033] (1) Pretreatment: Add Dynacoll 7360, CMA-24, DL-2000D, EVA, and rosin resin into the reaction kettle, heat to 150°C and stir for 30 minutes, let the raw materials fully melt and mix evenly, then cool down to 110°C, and stir Under vacuum dehydration for 1.8 hours, then lower the temperature to 80°C;

[0034] (2) Preparation of isocyanate-terminated prepolymer: Take the measured 4,4'-diphenylmethane diisocyanate, preheat to 60°C, add to the reaction kettle and stir evenly, in N 2 The prepolymerization reaction was carried out at 100°C under protection for 140 minutes, and the NCO% content was detected to be 2.5% by di-n-butylamine titration method for sampling;

[0035] (...

Embodiment 2

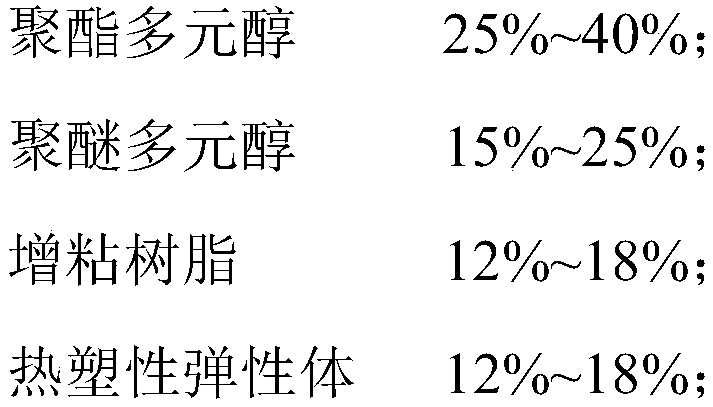

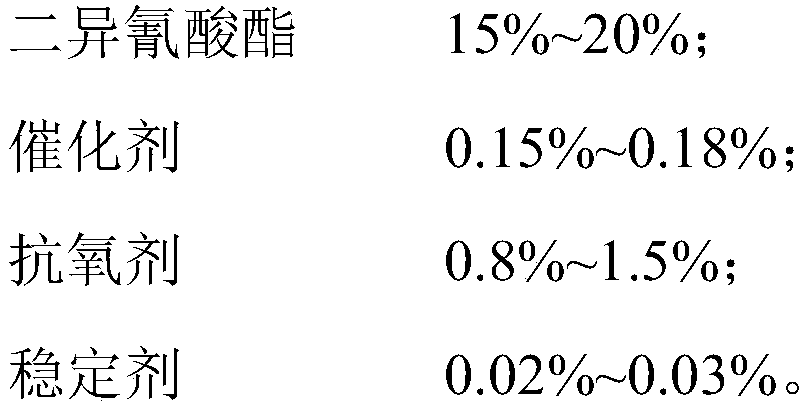

[0038] This embodiment provides a reactive polyurethane hot-melt adhesive for folding lithium-ion batteries in flexible packaging. In terms of mass percentage, the hot-melt adhesive includes the following components:

[0039]

[0040] The preparation steps of this hot melt adhesive are as follows:

[0041] (1) Pretreatment: Add Dynacoll 7380, MX-2325, DL-1000D, polymethacrylate, α-methylstyrene pure monomer resin into the reaction kettle and heat to 160°C and stir for 40 minutes to fully melt the raw materials and Mix well, then cool down to 108°C, vacuum dehydrate under stirring for 1.6 hours, then cool down to 78°C;

[0042] (2) Preparation of isocyanate-terminated prepolymer: Take the measured 4,4'-diphenylmethane diisocyanate, preheat to 58°C, add to the reaction kettle and stir evenly, 2 The prepolymerization reaction was carried out at 98°C under protection for 130 minutes, and the NCO% content was detected to be 2.6% by di-n-butylamine titration method for sampling;...

Embodiment 3

[0046]

[0047]

[0048] The preparation steps of this hot melt adhesive are as follows:

[0049] (1) Pretreatment: Add Dynacoll 7250, ODX-218, XCP-2000N, DL-3000D, hydroxyl-terminated thermoplastic polyester, and terpene resin into the reactor and heat to 170°C and stir for 20 minutes to fully melt and mix the raw materials evenly. Then lower the temperature to 112°C, vacuum dehydrate for 1.9 hours under stirring, and then lower the temperature to 82°C;

[0050] (2) Preparation of isocyanate-terminated prepolymer: Take the measured 4,4'-diphenylmethane diisocyanate, preheat it to 62°C, add it into the reaction kettle and stir evenly, and carry out prepolymerization at 102°C under the protection of argon. The polyreaction was carried out for 145 minutes, and the NCO% content was detected to be 2.4% by di-n-butylamine titration method for sampling;

[0051] (3) Addition of additives: After the prepolymerization is completed, add the metered catalyst triethylenediamine, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com