Waterproof, anti-seepage and high-temperature-resistant electrical insulation tape for telecommunication

An electrical insulation, waterproof and anti-seepage technology, which is applied in the field of communication materials, can solve problems such as breakage, achieve high-efficiency waterproof, improve use safety, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

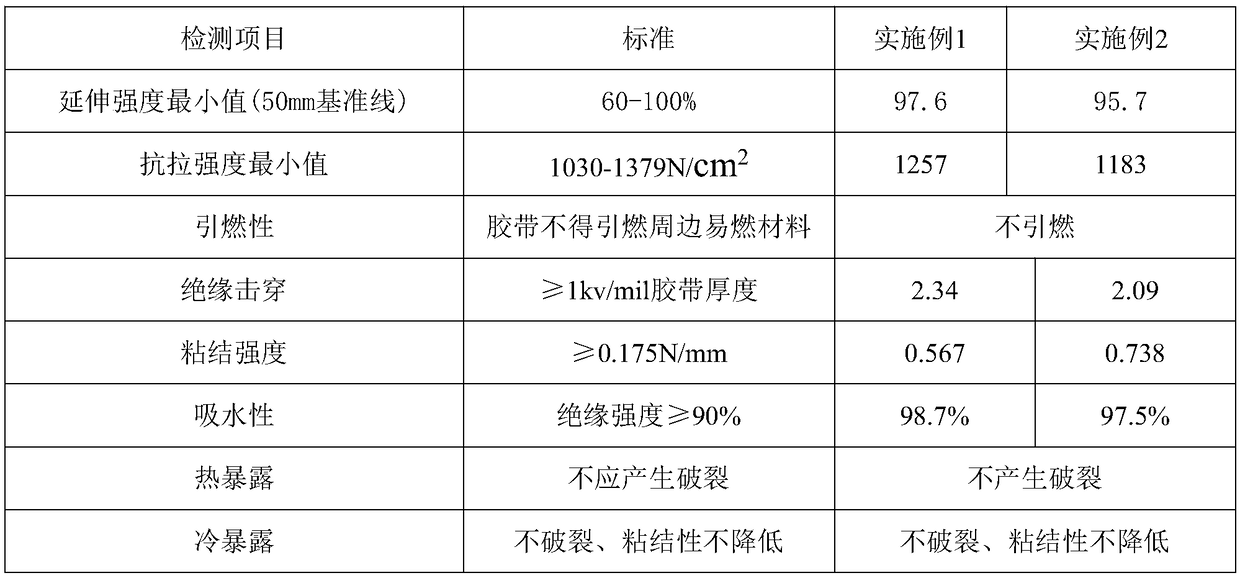

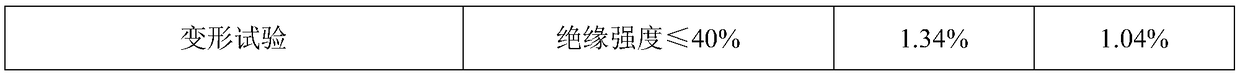

Embodiment 1

[0025] A waterproof, impermeable and high temperature resistant telecommunication electrical insulating tape;

[0026] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0027] A waterproof, impermeable, and high-temperature-resistant telecommunications electrical insulating tape, including the following specific technical solutions: The waterproof, impermeable, and high-temperature-resistant telecommunications electrical insulating tape includes the following mass fraction components:

[0028]1 part of nano-zinc powder, 13 parts of polyvinyl alcohol, 3 parts of tricresyl phosphate, 6 parts of polystyrene plastic debris, 7 parts of hydrogen peroxide, 6 parts of dimethyl silicone oil, 3 parts of impervious agent, oxidative curing 4 parts of agent, 7 parts of calcined kaolin, 5 parts of ethanol, 25 parts of polyvinyl chloride, 20 parts of polystyrene, 15 parts of sodium alginate, 2 parts of borax, 4 parts of softene...

Embodiment 2

[0042] A waterproof, impermeable and high temperature resistant telecommunication electrical insulating tape;

[0043] The technical problem to be solved by the present invention adopts the following technical solutions to realize:

[0044] A waterproof, impermeable, and high-temperature-resistant telecommunications electrical insulating tape, including the following specific technical solutions: The waterproof, impermeable, and high-temperature-resistant telecommunications electrical insulating tape includes the following mass fraction components:

[0045] 0.5 parts of nano-zinc powder, 8 parts of polyvinyl alcohol, 10 parts of tricresyl phosphate, 7 parts of polystyrene plastic debris, 6 parts of hydrogen peroxide, 5 parts of dimethyl silicone oil, 3 parts of impervious agent, oxidative curing 3.5 parts of agent, 11 parts of calcined kaolin, 6 parts of ethanol, 25 parts of polyvinyl chloride, 20 parts of polystyrene, 15 parts of sodium alginate, 4.5 parts of borax, 4 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com