Traditional Chinese medicine silver titanate composite porous material for burn wound healing, preparation method and application

A wound healing and porous material technology, applied in the field of medical materials, can solve the problems of no antibacterial activity and anti-infection effect, and can not deal with the susceptibility of burn wounds to infection, etc., to avoid toxicity and irritation, soft texture, and increase air permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

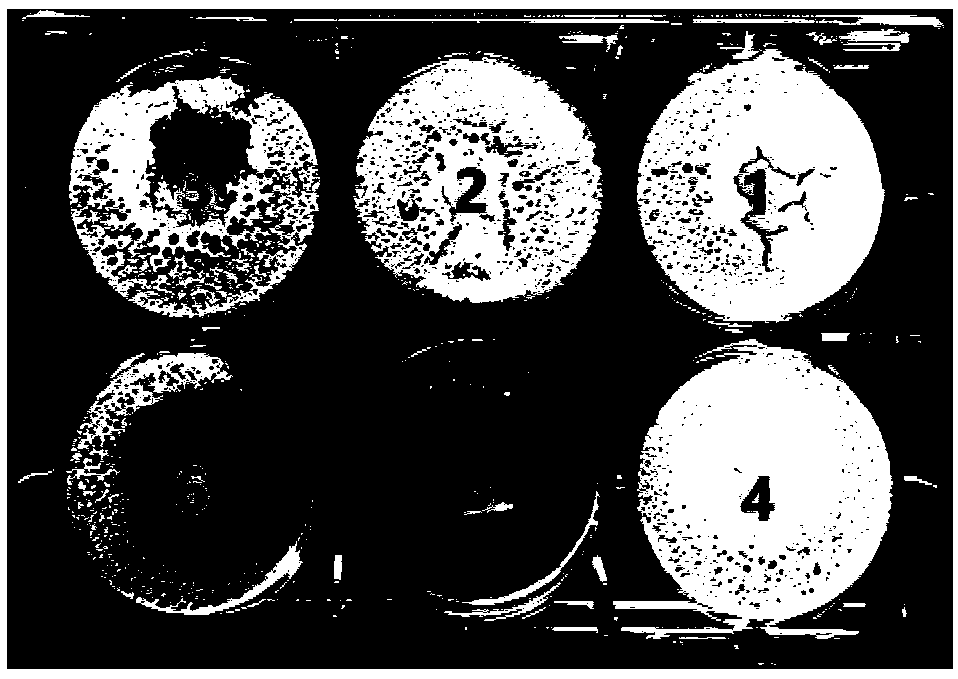

[0042] Screening of the ratio of Baijijiao and carboxymethyl chitosan in traditional Chinese medicine silver titanate composite porous material for burn wound healing

[0043] Crush the Baiji decoction pieces, add 7 times the amount of distilled water to soak for 12 hours, stir, filter, and the filtrate is set aside. The dregs are then soaked in 4 times the amount of water for 3 times, each time for 6 hours, and then filtered. The 4 filtrates were combined and concentrated, and the relative density was 1.10 (65°C). After cooling, add 95% ethanol to make the alcohol content reach 70%. Stir to precipitate a large amount of floc, leave it to stand, vacuum filter to dryness, add ethanol to the precipitate and stir, let stand, make it fully dehydrated (dehydration 3 times), suction filtration to dryness, so that the ethanol is volatilized, dried in an oven at low temperature, and grinded a little, to obtain yellow-brown dry powdered white and polysaccharide, that is, white and glu...

Embodiment 2

[0060] A method for preparing a traditional Chinese medicine silver titanate composite porous material for burn wound healing, comprising the following steps:

[0061] Adopt hydrothermal method and ultraviolet light photodeposition method to prepare silver titanate material: in 5ml tetrabutyl titanate (Sinopharm Group Chemical Reagent Co., Ltd.), drop 0.6ml concentration and be 40% hydrofluoric acid (Sinopharm Group Chemical Reagent Co., Ltd.) company), treated in a hydrothermal reaction kettle at 180°C for 36 hours, added silver nitrate with an intermediate mass of 1.0% to the intermediate, and deposited it with ultraviolet light for 30 minutes, and then put the final product at -20°C and a pressure of 1.0mBar. Freeze-dry for 12 hours to obtain the silver titanate.

[0062] Take 10mL of 100mg / mL baicalin solution, 10mL of Baijijiao glue with a concentration of 5%, and 30mL of carboxymethyl chitosan glue with a concentration of 4%. After mixing, place them in a water bath at 5...

Embodiment 3

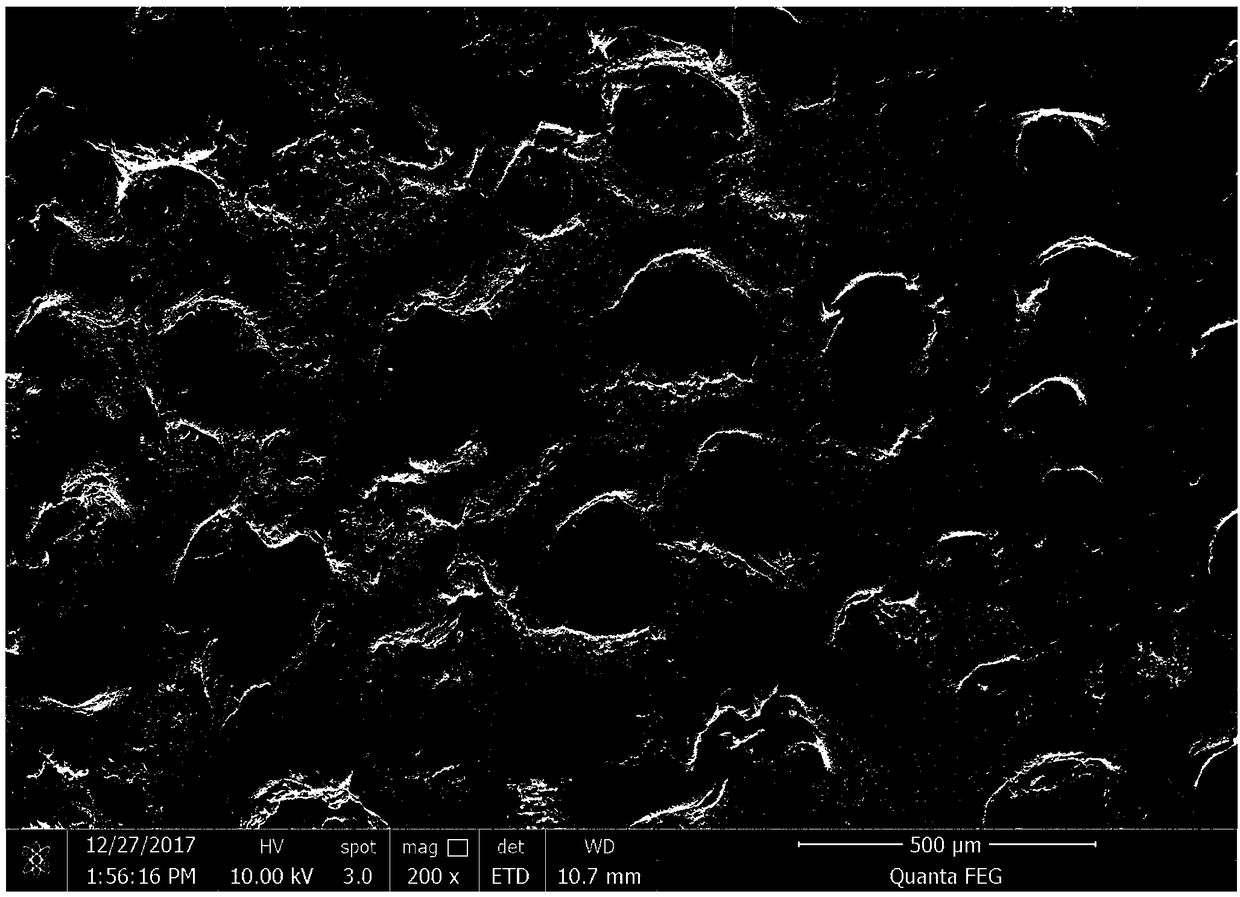

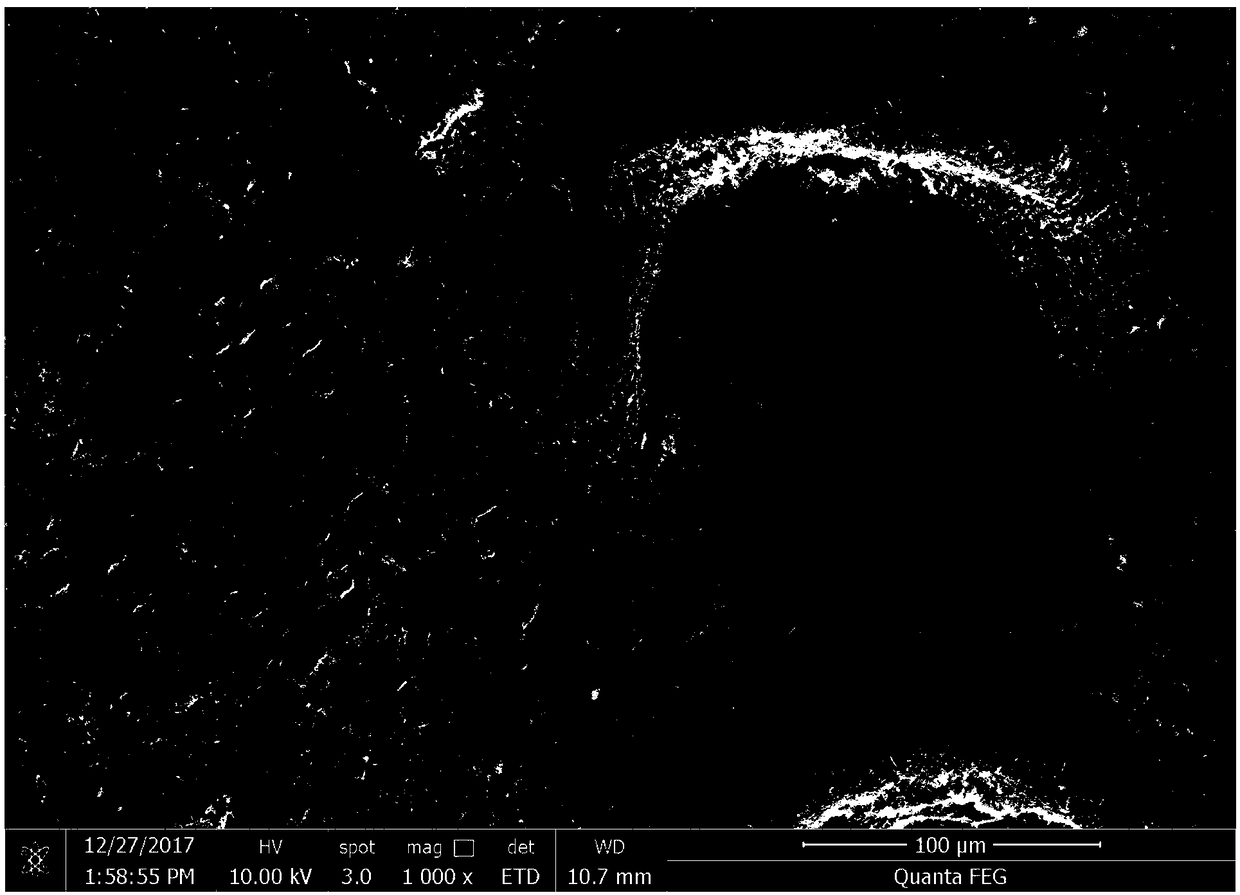

[0065] Morphological observation of traditional Chinese medicine silver titanate composite porous material for burn wound healing

[0066] Take the traditional Chinese medicine silver titanate composite porous material used for burn wound healing prepared in Example 2, place it on a sample plate with double-sided adhesive tape, observe it under a scanning electron microscope after gold plating, and obtain the traditional Chinese medicine for burn wound healing Morphology of silver titanate composite porous materials. Such as figure 2 , image 3 , Figure 4 as shown, figure 2 It is the scanning electron microscope figure (SEM 200X) of the traditional Chinese medicine silver titanate composite porous material that is used for burn wound healing that embodiment 2 prepares, image 3 It is the scanning electron micrograph (SEM 1000X) of the traditional Chinese medicine silver titanate composite porous material that is used for burn wound healing that embodiment 2 prepares, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com