A kind of binary mesoporous-microporous hierarchical biochar based on lotus leaf and its preparation method and application

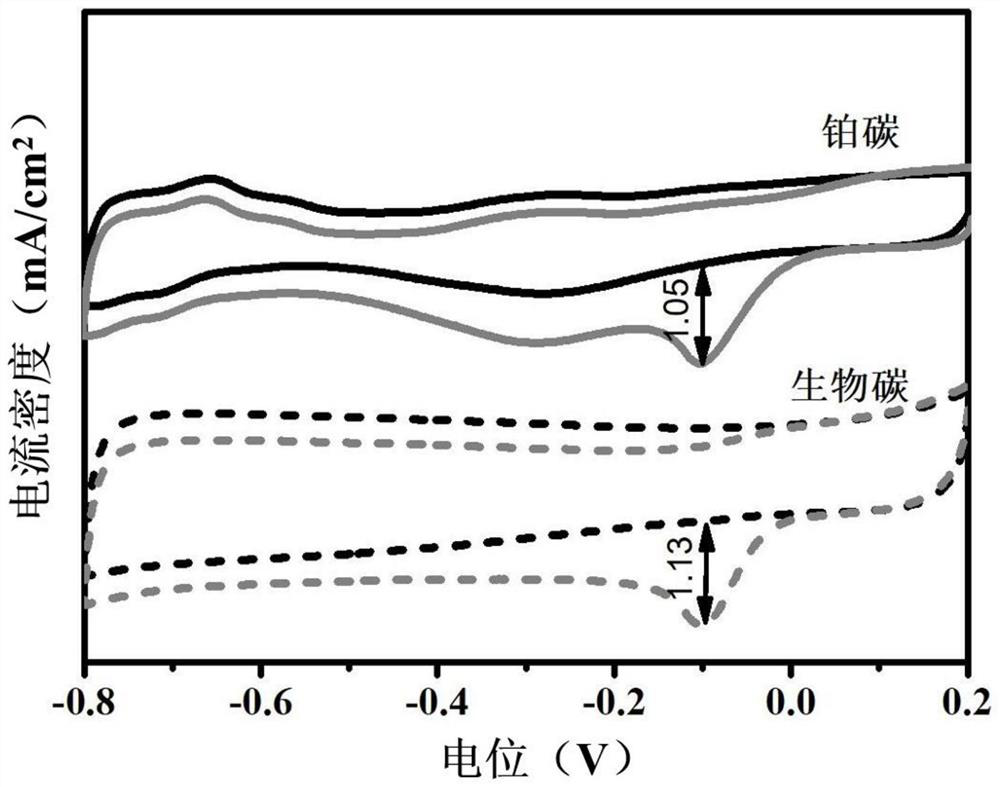

A binary mesoporous, bio-carbon technology, applied in carbon preparation/purification, structural parts, chemical instruments and methods, etc., can solve the problem that MFCs cannot really achieve commercial application, cannot be widely promoted and applied, and catalysts are expensive, etc. problem, to achieve the effect of excellent electrochemical performance, excellent electrochemical performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of lotus leaf-based binary mesoporous-microporous hierarchical structure biochar, comprising the following steps:

[0027] 1) The lotus leaf is cleaned and dried;

[0028] 2) Add the dried lotus leaf and metal chloride-ammonium salt mixed solution into the reaction kettle, fill it with protective gas, raise the temperature to 100-200°C at a heating rate of 5-10°C / min, and perform hydrothermal carbonization;

[0029] 3) After drying the hydrothermally carbonized lotus leaves, put them into a carbonization furnace, fill them with protective gas, and carry out high-temperature carbonization at 700-1100° C. to obtain a biochar with binary mesoporous-microporous hierarchical structure based on lotus leaves.

[0030] Preferably, the lotus leaves in step 1) are lotus leaves in subtropical regions.

[0031] Preferably, the drying in step 1) is carried out at 35-75° C., and the drying time is 12-24 hours.

Embodiment 1

[0043] A preparation method of lotus leaf-based binary mesoporous-microporous hierarchical structure biochar, comprising the following steps:

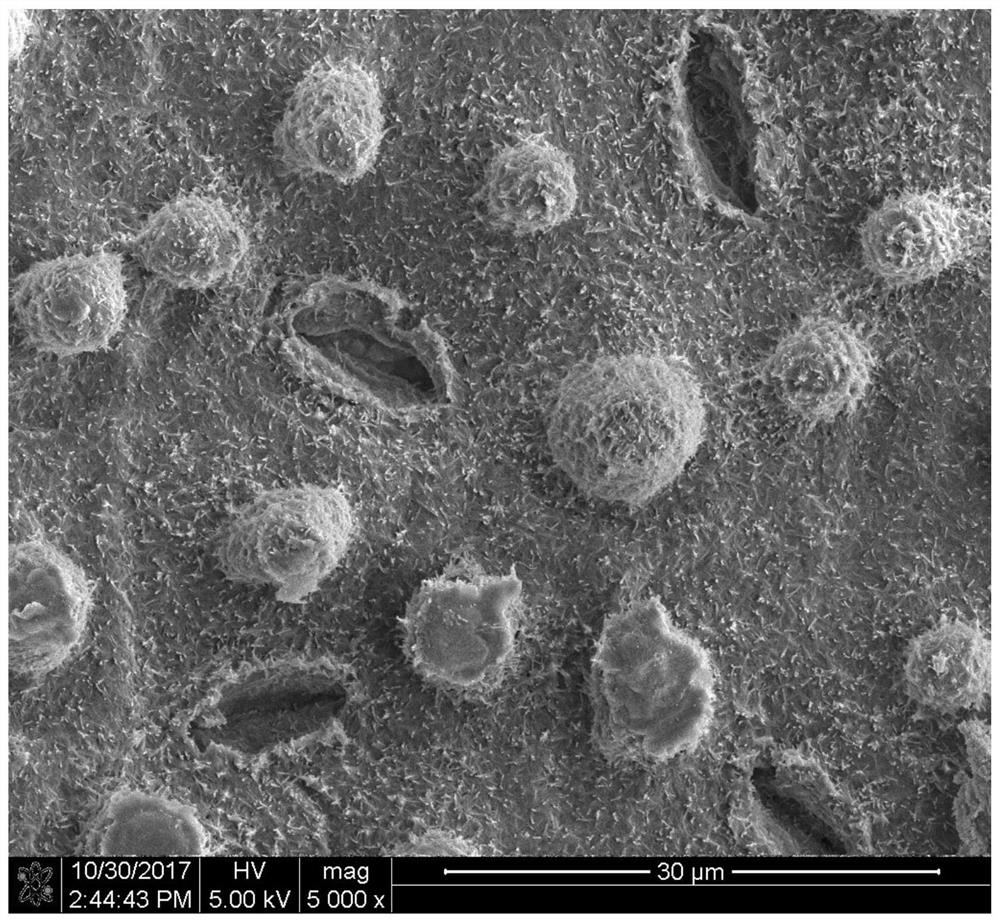

[0044] 1) Use deionized water and absolute ethanol to wash the lotus leaf (SEM image as shown in figure 1 shown) and cleaned, then cut into small pieces of 3.0cm×3.0cm, and dried in an oven at 40°C for 12 hours;

[0045] 2) Add the dried lotus leaf and zinc chloride-ammonium sulfate mixed solution (the molar ratio of zinc chloride to ammonium sulfate is 1:1, and the concentration of zinc chloride is 0.10mol / L) into the reactor, and fill it with nitrogen , and then heated up to 160°C at a heating rate of 10°C / min for 2 hours of hydrothermal carbonization;

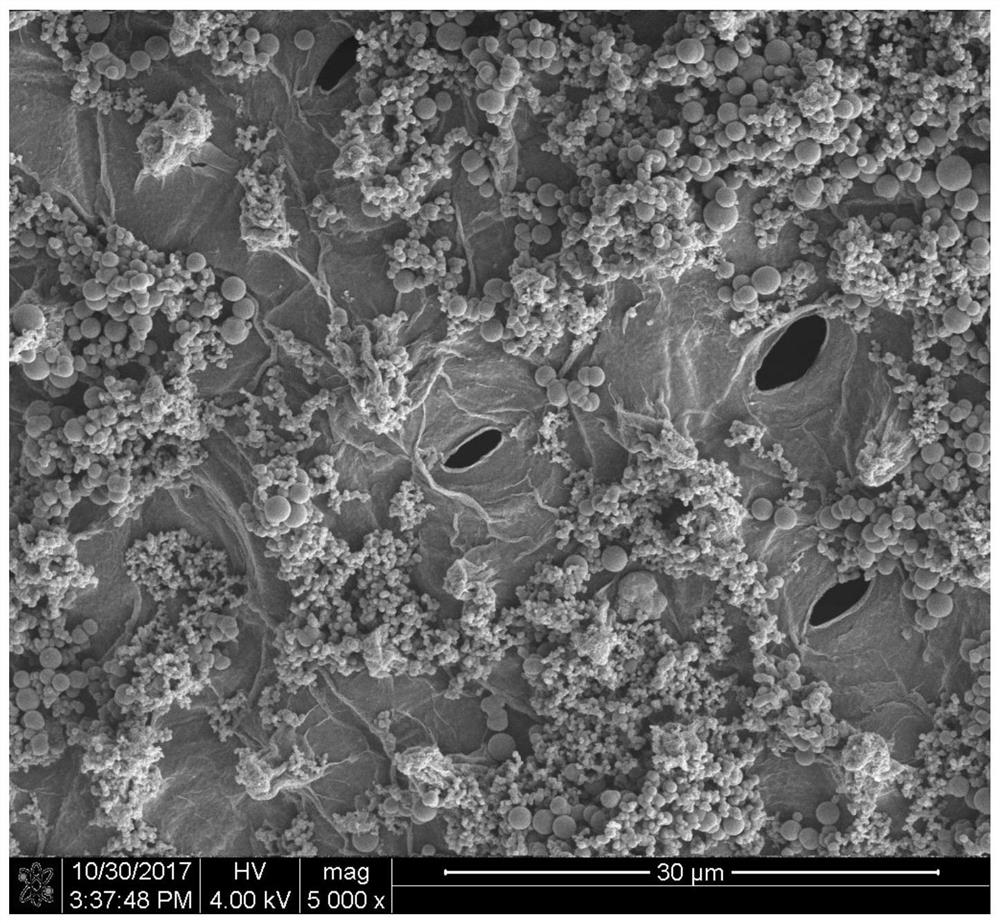

[0046] 3) Put the hydrothermally carbonized lotus leaf in an oven to dry at 60°C for 2 hours, then add it to a carbonization furnace, fill it with nitrogen, and carry out high-temperature carbonization at 900°C for 2 hours to obtain a binary mesoporous-microporous multi-level struct...

Embodiment 2

[0050] A preparation method of lotus leaf-based binary mesoporous-microporous hierarchical structure biochar, comprising the following steps:

[0051] 1) Wash the lotus leaves with deionized water and absolute ethanol, cut them into small pieces of 3.0cm×3.0cm, and dry them in an oven at 35°C for 15 hours;

[0052] 2) Add the dried lotus leaf and zinc chloride-ammonium sulfate mixed solution (the molar ratio of zinc chloride to ammonium sulfate is 1:2, and the concentration of zinc chloride is 0.07mol / L) into the reactor, and fill it with nitrogen , and then heated up to 200°C at a heating rate of 8°C / min for 2 hours of hydrothermal carbonization;

[0053] 3) The hydrothermally carbonized lotus leaves were dried in an oven at 60°C for 2 hours, then added to a carbonization furnace, filled with nitrogen, and subjected to high-temperature carbonization at 800°C for 5 hours to obtain a binary mesoporous-microporous multi-level structure based on lotus leaves Structural biochar. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com