A kind of preparation method of salt-resistant thickener

A thickener and salt-resistant technology, applied in the field of textile printing, can solve the problems of difficult mixing, copolymerization, poor water solubility, affecting the effect of hydrophobic modification, etc., and achieve the effect of improving thickening performance and salt-resistant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

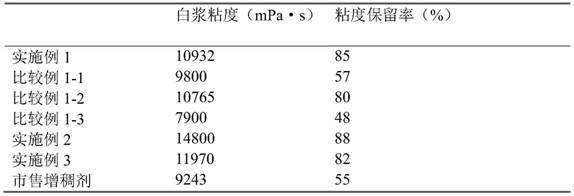

Examples

Embodiment 1

[0018] Mix ammonia water and acrylic acid monomer to a pH value of 6.5, add crosslinking agent polyethylene glycol (400) diacrylate, the amount of crosslinking agent accounts for 0.5% of the mass of acrylic acid monomer, stir evenly to obtain a water phase; , 2-acrylamido sodium dodecyl sulfonate and 5# white oil are made into oil phase, the consumption of span80 accounts for 2% of acrylic acid monomer quality, the consumption of 2-acrylamido sodium dodecyl sulfonate accounts for 5% of the mass of the acrylic acid monomer, the ratio of 5# white oil to the mass of the acrylic acid monomer is 0.5:1; slowly add the water phase to the oil phase under stirring conditions, emulsify at 1000 rpm for 90 minutes, then add the initiator dropwise aqueous solution, the initiator aqueous solution is a mixed solution of ammonium persulfate and sodium bisulfite, wherein the mass ratio of ammonium persulfate to sodium bisulfite is 4:1, and the total mass of the initiator accounts for 1.2% of th...

Embodiment 2

[0026] Mix ammonia water and methacrylic acid monomer to a pH value of 7, add a crosslinking agent polyethylene glycol (600) diacrylate, the amount of the crosslinking agent accounts for 1.0% of the mass of the methacrylic acid monomer, stir evenly, and obtain an aqueous phase thing; span80, sodium 2-acrylamido octaalkylsulfonate and aviation kerosene are formulated into an oil phase, and the consumption of span80 accounts for 5% of the mass of methacrylic acid monomer; The dosage accounts for 15% of the mass of methacrylic acid monomer, and the mass ratio of aviation kerosene to methacrylic acid monomer is 0.6:1; the water phase is slowly added to the oil phase under stirring conditions, and after emulsification at 1500 rpm for 60 minutes, Initiator aqueous solution is added dropwise, and initiator aqueous solution is the mixed solution of ammonium persulfate and sodium bisulfite, wherein, the mass ratio of ammonium persulfate and sodium bisulfite is 6:1, and total mass of ini...

Embodiment 3

[0028] Mix ammonia water and itaconic acid monomer to a pH value of 6.8, add a cross-linking agent polyethylene glycol (400) diacrylate, the amount of the cross-linking agent accounts for 0.8% of the mass of itaconic acid monomer, stir evenly, and obtain an aqueous phase thing; span80, sodium 2-acrylamido octane sulfonate and aviation kerosene are formulated into an oil phase, and the consumption of span80 accounts for 3% of the itaconic acid monomer quality; The dosage accounts for 10% of the mass of itaconic acid monomer, and the mass ratio of aviation kerosene to itaconic acid monomer is 0.55:1; the water phase is slowly added to the oil phase under stirring conditions, and after 75 minutes of high-speed emulsification at 1200 rpm, Add dropwise initiator aqueous solution, initiator aqueous solution is the mixed solution of ammonium persulfate and sodium bisulfite, wherein, the mass ratio of ammonium persulfate and sodium bisulfite is 5:1, and initiator total mass accounts fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com