Composite metal hydroxide as well as preparation method and application thereof

A hydroxide and composite metal technology, applied in the field of electrocatalytic materials, can solve problems such as inability to be used in a large area, limited earth reserves, high price of precious metal catalysts, etc., to achieve suitable mass production, controllable coating thickness, and superior catalysis active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

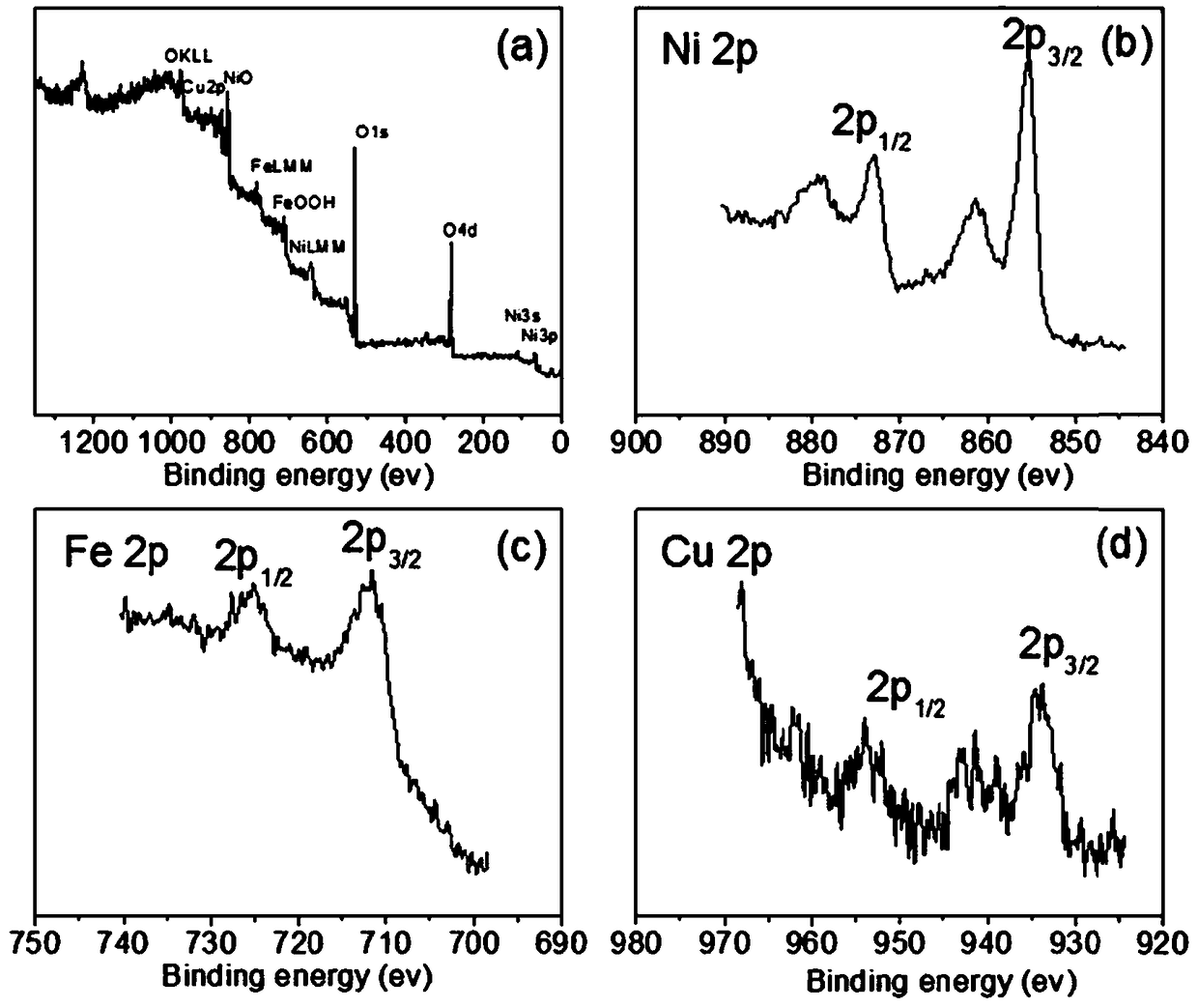

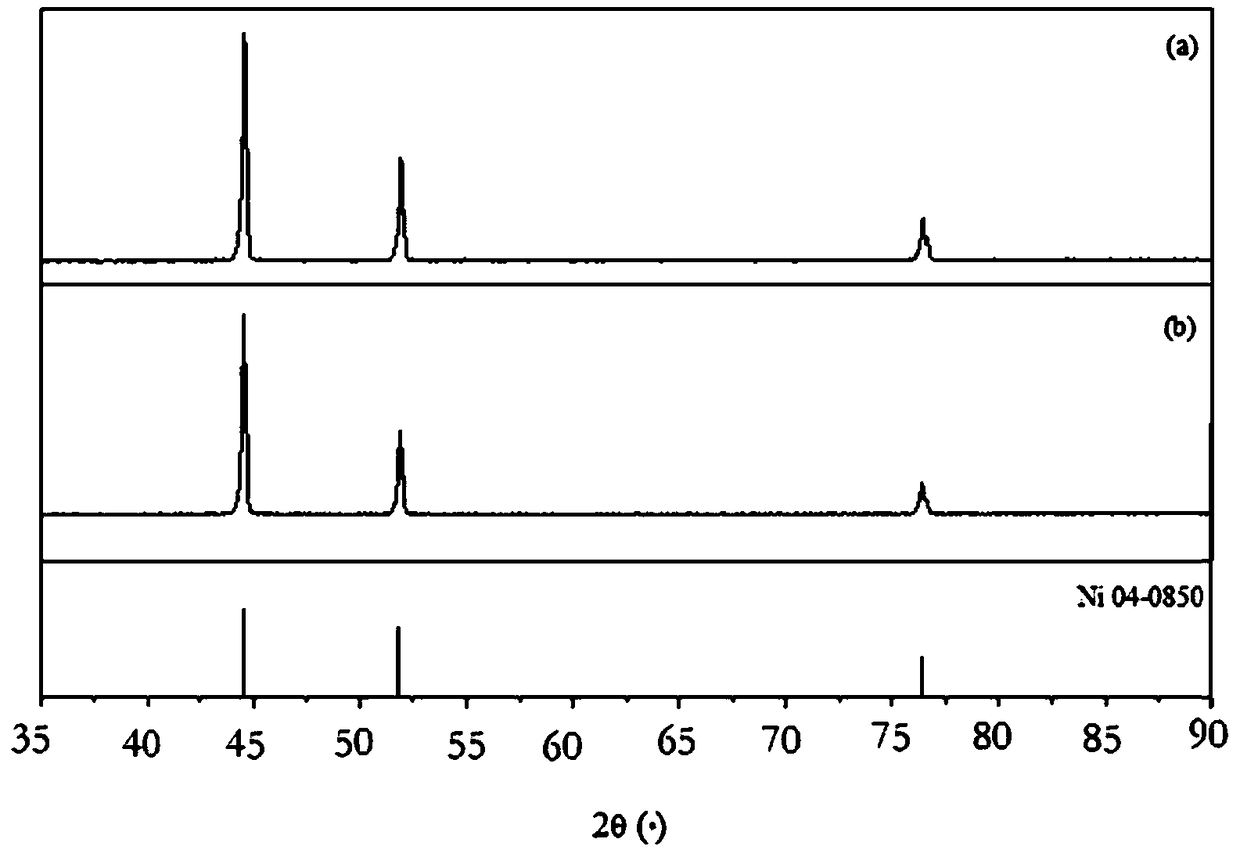

Embodiment 1

[0034] Dissolve 10 mmol of nickel sulfate, 5 mmol of iron sulfate, and 10 mmol of copper sulfate in 100 mL of deionized water, stir well, add ammonia water, and set aside. Prepare saturated sodium carbonate and sodium bicarbonate buffer solution, pour the spare metal salt solution into the buffer solution, stir evenly, and pour into the electrolytic tank. Cut 1*2cm of foamed nickel as the substrate, and switch on the anode after sufficient cleaning, and pass in 10mA / cm 2 The current is taken out after 10 minutes, rinsed three times with absolute ethanol, rinsed three times with deionized water, and dried at 100°C to obtain the nano-layered nickel-iron-copper hydroxide OER catalyst.

Embodiment 2

[0036] Dissolve 10mmol nickel nitrate, 5mmol ferric nitrate, and 10mmol copper nitrate into 100mL deionized water, stir well, add disodium edetate, and set aside. Prepare sodium carbonate and sodium bicarbonate buffer solution (sodium carbonate 10.3 g, sodium bicarbonate 1.2 g), pour the spare metal salt solution into the buffer solution, stir evenly, and pour it into the electrolytic tank. Cut 1*2cm of foamed nickel as the substrate, and switch on the anode after sufficient cleaning, and pass in 10mA / cm 2 The current is taken out after 10 minutes, rinsed three times with absolute ethanol, rinsed three times with deionized water, and dried at 100°C to obtain the nano-layered nickel-iron-copper hydroxide OER catalyst.

Embodiment 3

[0038] Dissolve 20 mmol nickel nitrate, 5 mmol ferric nitrate, and 20 mmol copper nitrate in 100 mL deionized water, stir well, add ammonia water, and set aside. Prepare saturated sodium carbonate and sodium bicarbonate buffer solution, pour the spare metal salt solution into the buffer solution, stir evenly, and pour into the electrolytic tank. Cut 1*2cm of foamed nickel as the substrate, and switch on the anode after sufficient cleaning, and pass in 10mA / cm 2 The current is taken out after 10 minutes, rinsed three times with absolute ethanol, rinsed three times with deionized water, and dried at 100°C to obtain the nano-layered nickel-iron-copper hydroxide OER catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com