Conductive flame-retardant polyester as well as preparation and application thereof

A flame retardant polyester and flame retardant technology, which is applied in the field of textile fibers, can solve the problems of lack of hydrophilic structure between molecules, poor antistatic property, endangering people's health, etc., and achieves good antistatic effect, high dimensional stability, Excellent flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

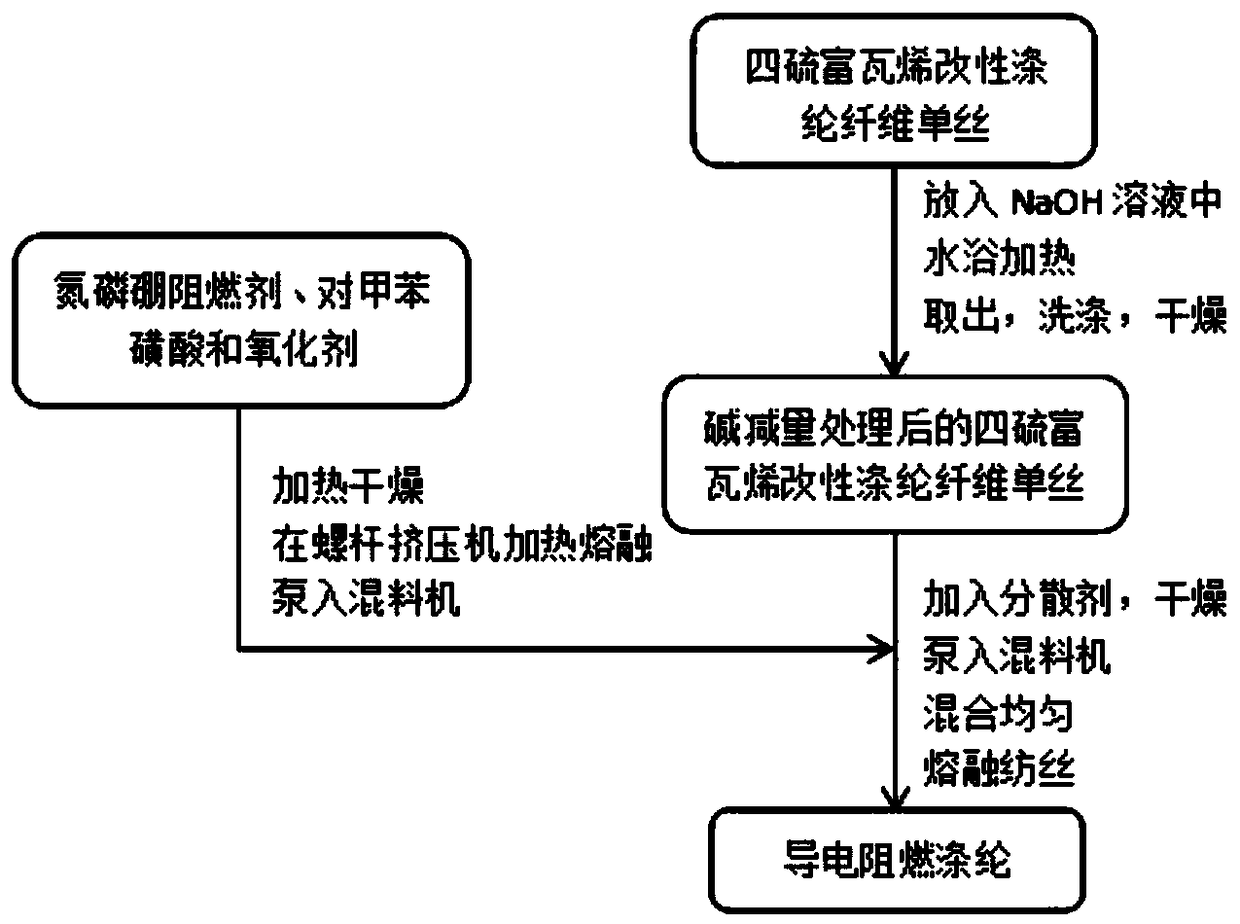

Method used

Image

Examples

Embodiment 1

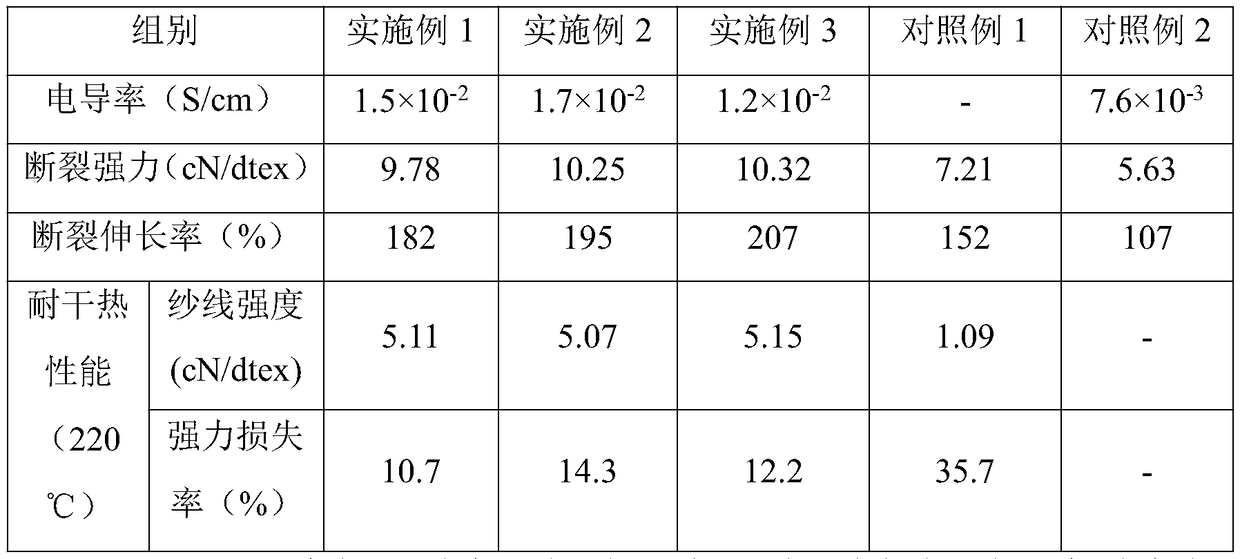

[0026] Embodiment 1 Preparation of conductive flame-resistant polyester

[0027] Raw material composition: 120 parts of tetrathiafulvalene modified polyester fiber, 20 parts of nitrogen, phosphorus and boron flame retardant, 10 parts of hexenyl bisstearamide, 1 part of p-toluenesulfonic acid, 20 parts of sodium hypochlorite;

[0028] Tetrathiafulvalene modified polyester fiber is prepared by the following method: HCl is used as doping acid, and tetrathiafulvalene and HCl are mixed in a ratio of 1:1 to form HCl / tetrathiafulvalene Mixing solution, adding lauroyl peroxide to obtain a mixed solution; padding the polyester fiber in the mixing solution during continuous operation, and leaving the yarn at room temperature after being drawn away from the padding area to make the mixing of the yarn surface The liquid is oxidatively polymerized in a non-liquid environment, and after 5 hours, a conductive tetrathiafulvalene modified polyester fiber is obtained.

[0029] Nitrogen, phosph...

Embodiment 2

[0034] Embodiment 2 Preparation of conductive flame-resistant polyester

[0035] Raw material composition: 150 parts of tetrathiafulvalene modified polyester fiber, 40 parts of nitrogen, phosphorus and boron flame retardant, 15 parts of liquid paraffin / / calcium stearate, 5 parts of p-toluenesulfonic acid, 30 parts of sodium percarbonate;

[0036] Tetrathiafulvalene modified polyester fiber is prepared by the following method: HCl is used as doping acid, and tetrathiafulvalene and HCl are mixed in a ratio of 1:1 to form HCl / tetrathiafulvalene Mix the solution, add azobisisobutyronitrile to obtain the mixed solution; pad the polyester fiber in the mixed solution during continuous operation, and leave the yarn at room temperature after being drawn away from the padding area to make the surface of the yarn The mixed liquid is oxidatively polymerized in a non-liquid phase environment, and conductive tetrathiafulvalene modified polyester fibers are obtained after 5-6 hours.

[0037...

Embodiment 3

[0042] Embodiment 3 Preparation of conductive flame-resistant polyester

[0043] Raw material composition: 137 parts of tetrathiafulvalene modified polyester fiber, 29 parts of nitrogen, phosphorus and boron flame retardant, 13 parts of cadmium stearate, 3 parts of p-toluenesulfonic acid, 25 parts of potassium perborate;

[0044] Tetrathiafulvalene modified polyester fiber is prepared by the following method: HCl is used as doping acid, and tetrathiafulvalene and HCl are mixed in a ratio of 1:1 to form HCl / tetrathiafulvalene Mixed solution, adding tert-butyl peroxybenzoate to obtain a mixed solution; the polyester fiber is padded in the mixed solution during continuous operation, and the yarn is led away from the padding area and left at room temperature to make the yarn The mixed liquid on the surface is oxidatively polymerized in a non-liquid phase environment, and conductive tetrathiafulvalene modified polyester fibers are obtained after 5-6 hours.

[0045] Nitrogen, phosp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com